Puzzled by Global VOC and Emission Standards in Architectural Paints?

Credit: Eastman Chemical Co.

Credit: Eastman Chemical Co.

Credit: Eastman Chemical Co.

Credit: Eastman Chemical Co.

Credit: Eastman Chemical Co.

Credit: Eastman Chemical Co.

Jennifer Cogar, Global Application Technology Leader, Architectural Coatings, Eastman Chemical Co., recently presented a webinar on the global volatile organic compound (VOC) and emissions standards for architectural paints. Following is key information gleaned from her presentation. For a more detailed understanding of the “standards puzzle”, you can view the webinar on demand at www.pcimag.com/events.

Q: What is the difference between VOC and emissions?

A: Regulation of VOC is focused on reducing ozone and impact on the environment. To accomplish this goal, the regulations focus on the VOC content in the can. In-can content regulations are defined for both raw materials and final formulations. The materials that are defined as VOC in architectural coatings vary by region. In comparison, emissions are more concerned about the quality of indoor air and the impact on human health. For emissions, the focus is on emission of organic compounds from dry paint films, and this is defined for the entire formulation.

Q: What is the definition of an effective architectural VOC regulation?

A: There are basically three components that go into an effective architectural VOC regulation. 1) You need a definition of what is considered a VOC, preferably for the raw material, but also for the formulated paint; 2) You need to define product categories for the paints and establish the VOC limits for these categories; 3) You need to have an official test method(s) to determine whether or not the paints are meeting the limits.

Q: How do the different global regions define and measure VOC?

A: VOC definitions, limits and calculations are different all over the world. In the United States and Canada, a VOC is any compound of carbon that participates in atmospheric photochemical reactions, excluding carbon monoxide, carbon dioxide, carbonic acid, metallic carbides, carbonates and ammonium carbonate. It is not a simple definition, as it is sometimes hard to tell if something is participating in atmospheric photochemical reactions. VOC in the United States and Canada is measured by ASTM Method 24. Method 24 includes a number of tests and calculations, including determination of volatiles at elevated temperature and determination of water content. Work is being done to develop a standardized GC (gas chromatograph) test method.

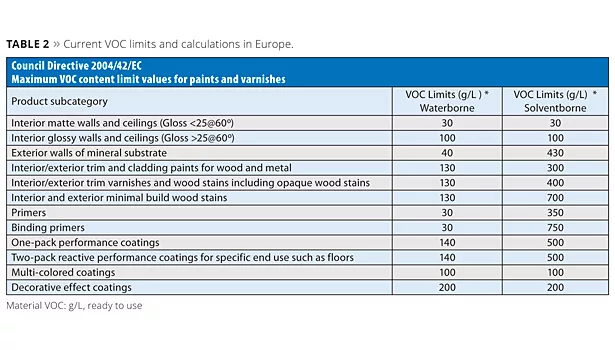

The European Union defines VOC as any organic compound having an initial boiling point less than or equal to 250 ºC under standard pressure of 101.3 Pa. This is a much more straightforward definition than we have in the United States, which makes it very easy to classify raw materials and determine what is going to contribute to the VOC content of a paint. Formulated coating VOC is tested by GC (ISO 11890-2).

China has standards for both interior architectural coatings (National Standard GB 18582-2008) and exterior wall coatings (GB 24408-2009). Korea also has mandatory government regulations, primarily for the Seoul area. Both countries define VOC very similarly as the European definition, as any organic compound with an initial boiling point lower than 250 ºC under standard pressure of 101.3 Pa. Like Europe, formulated coating VOC is tested by GC.

There are currently no mandatory VOC regulations in Latin America, so nothing has been defined. There is, however, a lot of activity going on in the region in defining what they want those regulations to look at. One of the leaders in this effort is Brazil. Brazil does have a committee in place working under ABRAFATI, which has agreed to use the Deco Directive definition (250 ºC boiling point), and also the same ISO testing (ISO 11890-2). Right now the methodology for the Brazil standard is in a comment period, allowing paint manufacturers the opportunity to comment on that standard. Brazil still needs to finalize the actual VOC limits for the different paint categories. Argentina has also established a committee, which is first taking a look at all of the different global regulations, in an effort to model their system on a program that already exists, rather than introducing a whole new set of standards. Columbia initially focused on using the U.S. EPA rule, but has since backed off and is investigating various other standards. Mexico is also starting to look at having VOC limits. Working with ANAFAPYT, they are trying to develop a Latin American Coatings Producers Federation, which will help bring standardization to the entire region. This is an effort that is really just beginning.

India does not currently have mandatory VOC requirements, but many companies focus on meeting Green Seal GS-11. Green Seal GS-11 defines VOC as materials with a boiling point above 280 ºC. As with many independent labeling programs, GS-11 also has a number of other requirements that must be met.

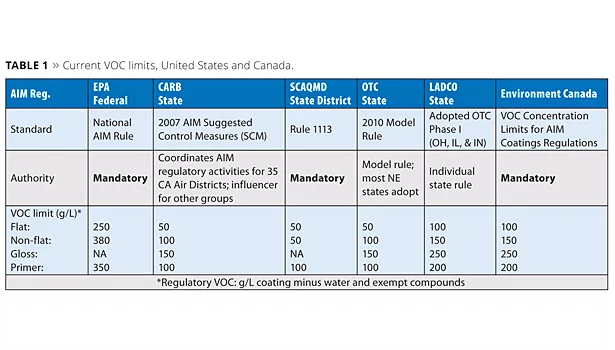

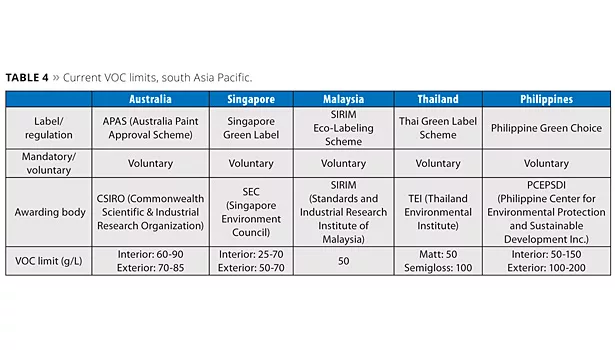

Q: What are the current VOC limits?

A: VOC limits vary by region and by paint type, and can be seen in Tables 1-4.

Q: What is the future direction of these limits?

A: Currently, in the United States we expect reduction of allowable VOC limits in SCAQMD (South Coast Air Quality Management District). In Europe and China there is more focus on the development of emissions standards. In Latin America we should see VOC standards being developed.

Q: Are there mandatory emissions standards?

A: Currently, all of the global emissions standards for wall paints are voluntary, except for the French Le Grenelle labeling regulation, and a program that applies to public-use buildings in Seoul, Korea. There are some emissions programs designated for use within specific building codes. Emission programs vary in the content allowed and sometimes include lists of “chemicals of concern,” which may have separate allowable limits. An example of a chemical of concern would be formaldehyde. There is one basic test, ISO 16000, that helps define the methodology used in many of the other standards that are based on chamber tests, although specific test conditions will vary in different standards.

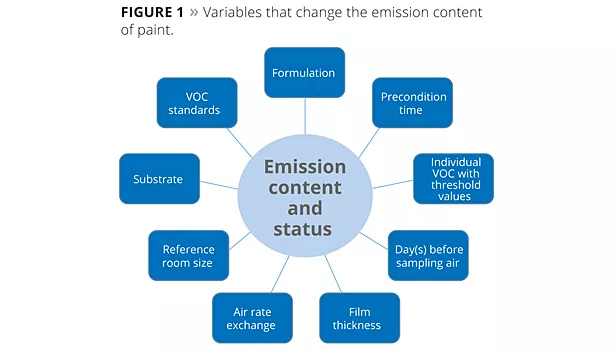

Q: What variables change the emission content of paint?

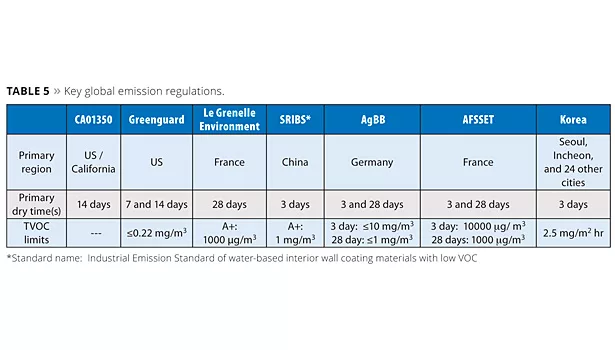

A: Measuring emissions is less direct than measuring VOC. There are numerous variables that impact the emissions content, and emissions have to be determined for each individual formulation. Figure 1 shows the many variables that can change the emissions content of a paint. The pigment volume concentration (PVC) of the formula can impact emissions. And, testing parameters such as substrate, film thickness and timing of sampling can also have a significant impact on emission levels. It is critical to understand the parameters for the specific emissions standard you are trying to achieve. Standards can vary, and each will list specific definitions and guidelines on how and what to measure along with the required limits (Table 5).

Q: How can formulators meet current VOC regulations without changing their formulations too much?

A: In discussions with our customers, we have found that minimizing reformulation time is extremely important to them. The versatility of a supplier’s portfolio allows them to offer suggestions that work across regions, formulation parameters and customer preferences. For example, in many regions, conventional coalescents like Eastman Texanol™ ester alcohol are not considered VOC, so reformulation can be focused on reducing glycol levels and additives that contain volatile solvents. In regions where the standards do consider Texanol a VOC, the best way to minimize reformulation is to simply reduce the Texanol to the required VOC level, then add a nonvolatile coalescent like Eastman Optifilm™ 400 enhancer to maximize the film formation. This approach minimizes the reformulation required and maintains performance most like the current higher-VOC formulation.

By Eastman Chemical Co., Kingsport, TN

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!