Industrial Coatings in Architectural Areas

Credit: Bayer

Credit: Bayer

Credit: 2009 AHA report

Credit: Bayer

Credit: Bayer

In your rush to check into a hotel, have you ever looked around and thought what a difference industrial coatings could make? At first glance, taking a coating technology that might be more at home on a bridge and applying it in a hotel lobby seems like a significant leap of faith. But these areas have more in common than you might think. Both require coatings that provide durability, cleanability and chemical resistance. Increasingly, the same properties that have made industrial coatings well-suited to large-scale infrastructure are now making them attractive for architectural applications.

When talking with key stakeholders along the building and construction value chain, one attribute they consistently sought was a more durable, scrubbable wall coating for walls, doors and trim in high-touch, high-traffic areas, such as hotel lobbies and hospitals.

Due to enhanced and innovative technology that is required in high-touch and high-scrubbed areas, industrial coatings help reduce the repaint cycle, keep areas safe and offer cost efficiencies in the architectural market.

We’re not talking about an incremental shift in durability or scrubbability. We are talking about an exponential improvement in durability, where the coatings are easy to clean repeatedly and possess excellent scrub and chemical resistance compared with higher-end traditional architectural coatings. We will share more details about the technology later in this article. First, let’s take a closer look at what we heard from the key stakeholders with whom we spoke.

What Decision Makers Want

We reached out to the market to dialog with key decision makers along the value chain. We spoke with architects, specification writers, paint contractors, and maintenance, facility management and environmental services personnel. During our conversations, we asked: What challenges do you face with current technologies and regulations? What does your perfect world for coatings look like? What attributes are you seeking in a coating solution? We listened to how they defined the problems and prioritized what they wanted:

- A very low-odor coating that would not disrupt operations;

- More durable, scrubbable wall coatings in high-touch areas;

- “Warmer” eggshell or matte coatings with durability (low sheen);

- An easy-to-clean, seamless surface;

- Less downtime;

- Ability to use in-house painters for cost savings;

- Reduced yearly maintenance costs.

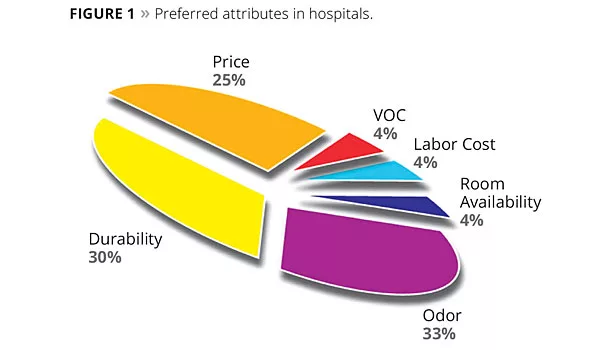

Figure 1 visualizes the specific attributes hospital administrators wanted. Low odor was the most sought-after property, with one-third of respondents rating it as the most important attribute. Durability placed a close second with 30 percent. Surprisingly, price came in third at 25 percent, demonstrating that participants understood the value of total vs. first costs.

In the healthcare market, hospital-acquired infection (HAI) is a major threat to human life. To combat HAI, stricter guidelines for the safe operation of healthcare facilities require areas of higher contamination risk, such as emergency, operating and procedure rooms, to be cleaned more often using stronger disinfectants. The increased cleaning with harsh chemicals detailed by new protocols is increasing demand for high-durability architectural wall coatings that are more scrubbable and chemical resistant. Of course, these priorities must be achieved with limited budgets in mind, so pricing is an important factor.

When all the results were tabulated, it came down simply to three key points. The majority of decision makers wanted an extremely durable coating available in low-sheen finishes that had low odor during application.

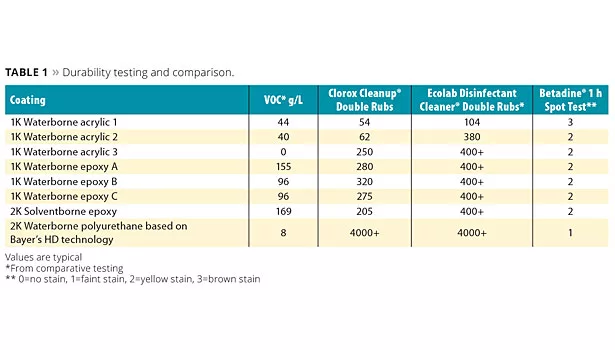

High-Durability Technology Passes the “Sniff” Test

We spent time analyzing the key stakeholders’ responses and determined that high durability (HD) coating technology based on two-component (2K) waterborne polyurethane technology could be formulated for use in high-touch, high-scrub areas to reduce long-term maintenance costs. HD coating technology is engineered to survive repeated, harsh scrubbing without compromising its integrity, surface sheen or color. To verify this, we conducted a comparative durability test of several coating formulations when cleaned with commonly used disinfection chemicals (Table 1 and Figure 2).

As the table and figure show, the HD wall coating technology based on 2K waterborne polyurethane performed better than the acrylic and epoxy formulations, resulting in a long-lasting finish with improved scrub and stain resistance. The HD technology was also tested for resistance to common staining agents such as coffee, ketchup, mustard, and red wine, with excellent stain resistance in all cases.

Additionally, the 2K waterborne polyurethane formulation had significantly lower VOC levels at 8 g/L compared with as much as 44 g/L for a typical waterborne acrylic formulation, and as much as 155 g/L for a waterborne epoxy formulation.

This is an important attribute as the focus on sustainable building and construction is creating demand for more environmentally friendly coating technology with reduced VOCs. The development of standards by the Master Painters Institute (MPI) and The Society for Protective Coatings (SSPC) are also guiding evaluation and application of these high-performance coatings in the built environment. For example, the MPI #252 standard was specifically created for this type of extreme durability architectural coating and takes into account scrubbability, chemical and disinfectant resistance, abrasion, and burnishing.

Of course, low VOC content does not always equate with low odor. As one interviewee quipped, “There’s VOC and then there’s stink.” We conducted an informal “sniff” test among our colleagues to qualitatively verify the low-odor properties of the HD coating technology. The results indicated that the HD coating technology based on 2K waterborne polyurethane has one of the lowest odor values along with two of the 1K waterborne acrylic formulations promoted as being “no odor.”

We verified these anecdotal results with a formal odor test conducted by an independent third party, a trained panel of judges from St. Croix Sensory Testing (Table 2). The HD coating technology had a low-odor intensity compared with 1K waterborne acrylic epoxy. Additionally, the smell of HD coating technology was ranked the most pleasant when compared with 1K waterborne acrylic latex and 1K waterborne acrylic epoxy formulations that advertise low odor as an attribute.

A Cost-Effective, Durable Coating Technology

Just as importantly, the increased durability can also help save maintenance costs. Compared with conventional wall paint, 2K waterborne polyurethane coatings built on HD coating technology are a minimum of six times more durable and scrubbable than acrylic coatings based on real-world applications. By significantly reducing the need to re-paint surfaces, HD wall coatings can lead to significant labor savings, lower maintenance costs and decreased raw material usage.

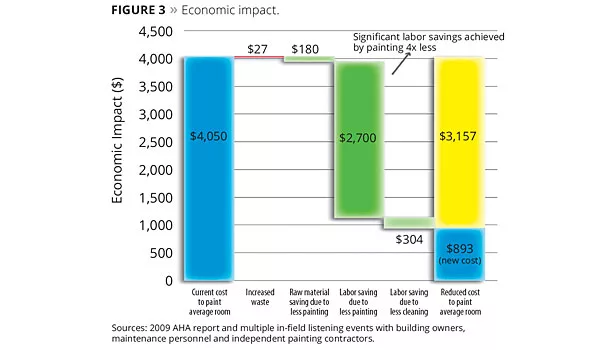

The potential economic impact is significant. HD coating technology can save as much as 80 percent in maintenance costs when compared with current costs to paint an average-sized room with traditional coatings. In the economic waterfall (Figure 3), red is additive to the current state, i.e. the large blue bar on the left indicates the total cost of labor and materials for one average-sized room being painted four times. The green bars are subtractive, i.e. savings over the current state. Yellow is the reduced cost to paint a room. The small blue bar is new state cost due to painting only once with the HD technology and includes raw material savings due to reduced waste.

At the same time, HD coatings provide similar ease of use, a wide color palette and a more pleasing, low-gloss finish. The concept of an HD coating available in a low-sheen finish is important to facility maintenance personnel as well as design architects. For maintenance personnel, it means they can hide drywall defects, nail pops and poorly finished joints. However, low sheen is important to design architects for totally different reasons. They want to design the commercial wall spaces to be warm, homey and aesthetically pleasing rather than being glossy and institutional-looking.

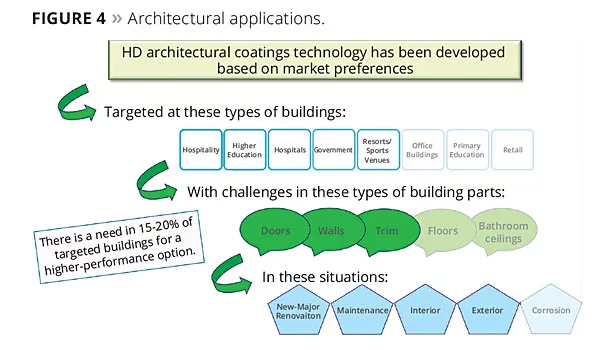

HD coating technology is also being used in other high-traffic commercial buildings, such as schools, universities, hotels and restaurants, where architects and facilities managers can benefit from the coatings’ unique combination of physical properties and aesthetic characteristics, such as color stability and low-gloss finishes, to provide good looks and long service (Figure 4).

Summary

HD coating technology based on 2K waterborne polyurethane is meeting market demand for architectural coatings with the expected durability, cleanability and chemical resistance of industrial coatings. The technology also fulfills additional architectural coating requirements of scrubbability, color retention, low VOC and odor, and low sheen. These coatings offer similar application properties to traditional acrylic wall paints, but offer much higher durability, nearly no odor and improved resistance to harsh disinfecting chemicals, such as strong bleach solutions and industrial cleaners.

As the advantages of utilizing HD two-component waterborne polyurethane technology for the architectural market become more well-known, these coatings will continue to migrate beyond their initial uses into hospitality, higher education, government, resorts and sports venues.

For more information, visit www.materialscience.bayer.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!