Innovative Coating Shields Metal From Rust

Credit: Rust Bullet

Credit: Rust Bullet

Credit: Rust Bullet

Credit: Rust Bullet

Credit: Rust Bullet

Credit: Rust Bullet

The physical integrity of a metal coating is as important as its chemical barrier properties in many applications. Selecting the best metal coating for an application requires evaluating all effects of the specific environment, including thermal and mechanical conditions. There are three main types of exposure to which coatings are subjected: atmospheric, immersion and underground exposure. The main difference between atmospheric exposure, immersion and underground exposure is weather resistance.

A coating under atmospheric exposure must endure a variety of conditions, including heating and cooling, oxidation, and wetting and drying. Immersion coatings are primarily subjected to water solutions ranging from pure water to high concentrations of various chemicals. Coatings used in underground applications must be resistant to ground water and soil forces, so they are generally applied thicker than atmospheric or immersion coatings.

In general, corrosive environments contain more than one active material, and the coating must resist penetration by a combination of oxidizers, solvents or both. Thus, the best barrier is one that resists "broadband" corrosion.

The anti-corrosion coatings market, like many other mature markets, is dominated by strong attitudes based on long experience. Most “old guard” engineers insist that to be effective, an anti-corrosion coating must be zinc-rich. Indeed, for decades zinc has been the gold standard in preventing corrosion on ships, bridges, drilling platforms, aircraft towers and many other structures in marine, industrial and agricultural applications.

Zinc is easy and cheap to produce, but vulnerable to abrasion and chemical attacks. Although zinc serves as a good cathodic protection agent, zinc oxide is permeable and will dislodge from the metal that it is designed to protect. In recent years, research has revealed serious environmental risks associated with zinc, so demand for an alternative has grown. This has led to the emergence of multi-layer epoxy-based coatings and zinc-filled conventional urethane coatings for corrosion mitigation and control. However, market acceptance has lagged. The hassle associated with laborious surface preparation and the time required to apply numerous catalyzed layers has caused resistance. In addition, companies concerned about environmental impact balk because many of these coating alternatives still contain zinc and other harmful ingredients.

Rust Bullet has created an innovative solution that addresses all the causes of corrosion and prevents further damage. Based on novel chemistry, the new coating uses a moisture-cured urethane to penetrate and dehydrate rust until it reaches the metal surface underneath instead of simply protecting metal beneath a zinc-loaded film or an unfilled resin. Using metallic flakes made of aluminum oxide, a protective micro-layer of metallic flakes forms in the resin matrix. As the coating cures, these metallic flakes align themselves to form an armor that reinforces the coating and physically shields the underlying metal.

How it Works

Aluminum is tougher than zinc in many ways. Aluminum oxide is less permeable and is more tightly formed than zinc oxide. More energy is required to produce aluminum than zinc, and therefore far more energy is required to oxidize aluminum than zinc. Type 2 aluminized steel with the Rust Bullet coating on each side resists atmospheric corrosion and has been shown to outlast zinc?coated sheet in industrial environments by as much as five to one. Typical applications for such coated steel include industrial and commercial roofing and siding, drying ovens, silo roofs, and housings for outdoor lighting fixtures and air conditioners.

The urethanes also play a key role. Rust Bullet is an aromatic urethane with aliphatic properties. Aliphatic and aromatic coatings differ in the types of polyols and isocyanates used in the formulation, hence their stabilities in atmospheric conditions differ significantly.

Aliphatic coatings are the superior choice for exterior protection because they are very stable when exposed to ultraviolet light, weathering and hydrolysis. The raw materials used in formulating aliphatic systems are generally more expensive and have higher viscosities than their aromatic counterparts.

Aromatic coatings are more heat and chemical resistant than the aliphatic coatings. Aromatic coatings do not stand up as well against atmospheric exposure since UV light causes yellowing and chalking.

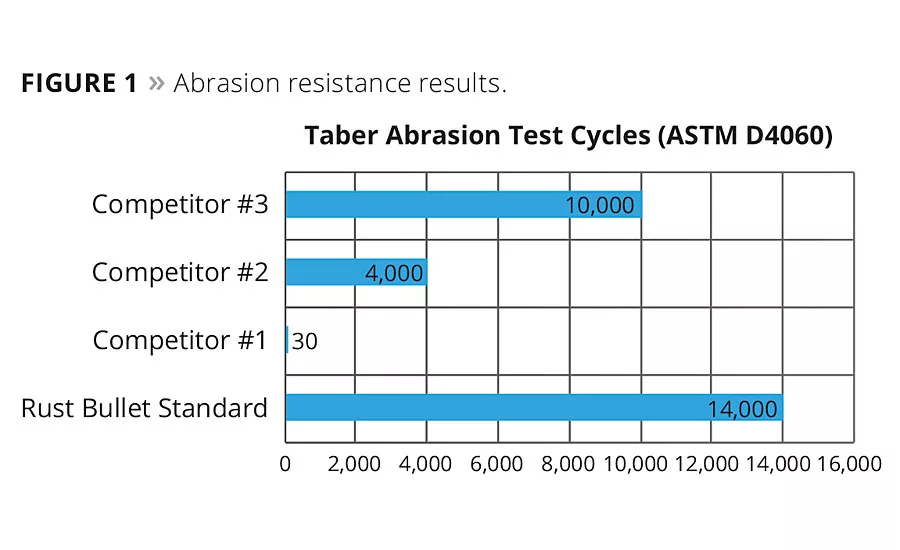

Due to the crosslinking density of a polyurethane coating (short chains and branching) it has a high degree of chemical and moisture resistance, as well as excellent adhesive properties. These qualities position polyurethane coatings as the best choice in protecting metals from corrosion. As elastomeric coatings do not perform as well in such areas, they are superior in terms of abrasion and impact resistance as well as protection for substrates that demonstrate more movement than metals (such as concrete). The Rust Bullet coating exhibits exceptional flexibility, and impact and abrasion resistance (Figure 1).

Rust Bullet is not a paint in the ordinary sense of the word. It requires no preparation, except the removal of large flakes of loose rust by light scraping or brushing. When applied, the coating does not form a film immediately, but rather penetrates the porous rust, reaching the metal underneath. Its method of protection dehydrates or dries out the corrosion through chemical activity, allowing the resin to solidify into a tough coating with phenomenal adhesion.

The corrosion particles become intertwined in the resin matrix and remain a permanent part of the coating. Subsequent coats fill any pinholes in the first coat and build up to provide an impenetrable coat. The layers of specialty aluminum form a new surface that protects the substrate against corrosion attack, also serving as a sacrificial anode. The polyurethane component provides a moisture barrier. As it cures, the urethane captures the dehydrated rust and incorporates it in the resin matrix -killing the rust permanently. With all the components combined, Rust Bullet becomes a corrosion-free, fire-retarding, chemical-resistant, UV-resistant and armor-like coating.

Application Process

Rust Bullet is a one part process, and the initial coat is ready for any subsequent coats within 2 to 4 hours. Although Rust Bullet does not require a catalyst for curing, cure can be accelerated by up to 80% by using Rust Bullet Rapid Fire accelerator. If a color other than metallic gray is desired, a topcoat may be applied within 24 to 48 hours after the final coat. The coating continues to cure for approximately 5 to 7 days. Epoxy coatings generally take 7-10 days to fully cure and allow the solvents to evaporate. Some even require force curing.

Due to the exothermic (heat-releasing) nature of the reaction during polyurethane curing, the coating can cure at almost any ambient temperature, even during cold months. Epoxy coatings require temperatures above 50 °F.

The Rust Bullet coating features a unique, “self?inspecting” property in that it fails almost immediately if it is incorrectly applied or if there is a problem with the surface preparation. Thus, polyurethane coatings can be inspected immediately after application and any defects will be visible and can be remedied quickly. This is not the case with an epoxy coating that requires an extended curing time and multiple-step process for remedy. Breaches in an epoxy coating are labor intensive and involve a large area outside the breach to be included in the repair. The Rust Bullet coating rarely experiences a breach but, when it does occur, the breach is easily repaired with simple scuffing and application of additional product.

Plural-component epoxy coatings require that precise mixing ratios be obtained at the point of application to avoid coating defects and failures. This is not an issue with the Rust Bullet coating, as it is a one?step, one?part, multiple-coat process.

The coating also has several other ancillary benefits besides corrosion protection, including:

- Contains no lead, zinc, chromates or heavy metals;

- Can withstand temperatures up to 325 °C for up to 72 hours continuously with no visible degradation;

- Has a fire spread index of 0 and smoke develop index of 0.5;

- Is approved by the US FDA for primary and secondary potable water storage or carry equipment;

- Encapsulates mold, preventing further microbial growth;

- Is UV, chip, scratch and chemical resistant;

- Can be applied with a one?step, multiple-coat process.

Conclusion

Rust Bullet has been proven through independent lab testing and university research to be an effective replacement to zinc-rich, environmentally unsound corrosion-control products. It can be used widely in many applications such as the automotive, oil and gas, marine and construction industries. By protecting the metal it ensures longer life of equipment and property, improves structural integrity and helps retain property value.

For more information on Rust Bullet, its technologies, standards and testing results visit www.rustbullet.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?height=200&t=1730486322&width=200)