Infrared Colorants for Cool Coatings

With concerns over the heat island effect in large cities and the general need to reduce energy consumption, there has been an increasing focus on colorants that utilize materials that reflect infrared wavelengths to reduce heat build. In addition, many countries are beginning to enact regulations to reduce energy consumption through the use of “cool” coatings. To meet these new requirements, coatings formulators are looking for the tools to support their development.

It is known that our Sun is the primary source of infrared energy. As these wavelengths are absorbed by any exterior surface, the surface becomes increasingly warmer. With black surfaces, the surface can be hot enough to burn skin. A black asphalt road at the peak of a bright summer day is hot because the dark color does not reflect the infrared radiation from the Sun away from its surface. In addition, this effect on a building’s dark-colored roof leads to warmer interior temperatures. In buildings without air conditioning, temperatures can be fatal. In buildings with air conditioning, the cost to cool interior space increases.

The use of infrared reflective pigments in coatings is a way to reflect infrared energy from the surface of the coating back into the atmosphere. This effect results in a cooler surface. While roof coatings are an obvious application for these colorants, there are many other applications where these types of colorants will benefit people and the environment. This article will provide an overview of the technology and its applications.

Total Solar Radiation

Total solar radiation consists of approximately 3% ultraviolet (UV), 44% visible and 53% infrared (IR) radiation. A substantial amount of the energy from UV wavelengths is absorbed by our atmosphere. In addition, the atmosphere absorbs or scatters a large amount of visible wavelengths in the blue region, which is the reason the sky appears blue. However, most of the energy in the IR wavelengths makes it to the surface of Earth, and heat is generated in the infrared wavelengths. The near-infrared wavelengths (approximately 700-2,500 nm) contain most of the heat energy produced by our Sun. Figure 1 shows the relative amount of solar energy in space as well as at Earth’s surface for ultraviolet, visible and infrared wavelengths.

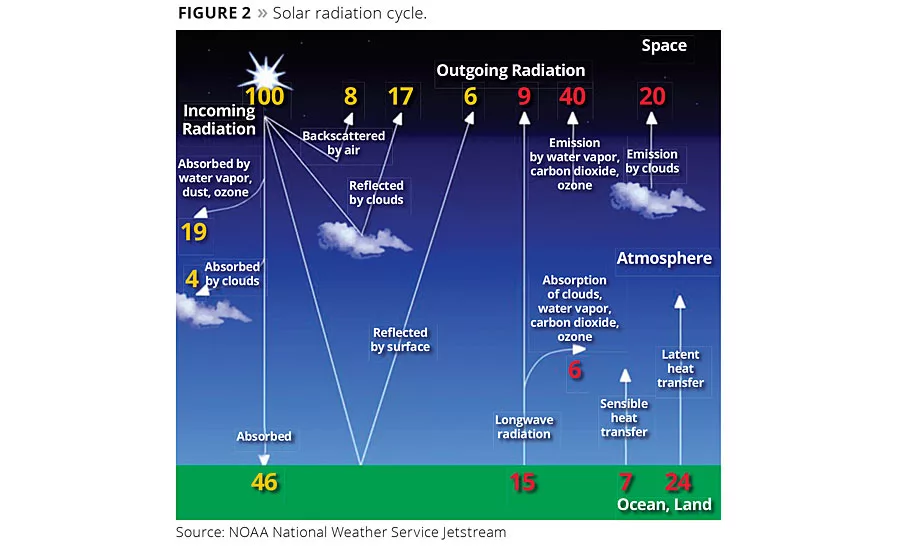

There is a normal daily process where Earth absorbs the Sun’s radiation during the day and radiates it back into space at night. Of the solar radiation reaching Earth’s atmosphere, approximately 23% is absorbed by the atmosphere, 31% is reflected back into space and 46% is absorbed by Earth’s surface. The Earth’s surface will radiate the absorbed radiation back into space through long-wave radiation, latent heat transfer and sensible heat transfer. Figure 2 depicts this process.

When the incoming and the outgoing radiation are at equilibrium, there is no change in the overall temperature of Earth’s surface. However, as Earth’s surface is covered by heat-absorbing materials such as black roofs, coated concrete, asphalt, or other dark surfaces, there is the potential to shift the balance of incoming and outgoing radiation.

Counteracting Absorbed Infrared Radiation

To counteract the effects of absorbed infrared radiation, there are coatings that will reflect IR radiation from the coated surface back into the atmosphere. Infrared-reflective coatings can be formulated with various pigments, metals (such as aluminum) or other materials to produce an IR-reflective barrier. These materials reflect wavelengths in the near-infrared region where most heat is generated. Due to the reflection of these IR wavelengths, the IR-reflective coated surface will be at a lower temperature when compared to traditional coatings.

A way to think about how this concept works is to consider how a white color appears in visible wavelengths. Since a white color reflects all wavelengths in the visible spectrum, the color appears white to the human eye. In fact, TiO2, which is used in the majority of white coatings, is a material that reflects infrared radiation as well as visible radiation. Conversely, a material that reflects no visible wavelengths appears black. Carbon blacks also absorb most infrared wavelengths and, therefore, become hotter than most colors. If we were able to see the color of a material in infrared wavelengths, a coating that reflects all IR wavelengths would appear white. Figure 3 depicts this phenomenon by showing a gray color formulated with non-IR‑reflective pigments such as carbon black and IR‑reflective pigments in visible and infrared wavelengths.

Because people desire more options when it comes to coloring a surface, white coatings are not the answer for many applications. There are numerous colored materials that provide a wide range of colors as well as reflectance of infrared wavelengths. These materials have been formulated into liquid dispersions by Chromaflo Technologies to provide ease of use by coatings formulators.

Color Options with IR-Reflective Colorants

When determining color options along with IR reflectance, the Total Solar Reflectance (TSR) of the material needs to be considered. TSR is the amount of solar radiation that is reflected away from the surface of a material and is expressed as a percentage. At higher TSR values, the surface will absorb less solar radiation and will have a lower temperature. The temperature change is measured in degrees and is known as Heat Build. White coatings have a TSR value of about 75%. The reason is because TiO2 reflects over 90% of the IR wavelengths between about 700-1,300 nm and drops off to about 30% around 2,500 nm. Carbon black coatings have a TSR value of about 5-10%. The TSR values of colored materials used in coatings range from about 25- 70%. Blends of any IR-reflective colorants will shift the TSR values of the pure colorants. Therefore, the proper choice of colorant for a particular color space is very important when targeting a specific TSR value for the final color.

Currently, this technology has application in roof coatings, exterior building coatings and joinery (window and door) coatings. These applications tend to focus on reducing the heat absorbed by the surface of a building in an effort to decrease energy costs by reducing the need to cool interior building spaces and protect the substrates from high temperatures. This technology would also be applicable in coatings formulated for exterior tanks, playground equipment, pool decks, concrete surfaces, automotive interiors and theme parks, among others. In summary, any exterior surface coating that could benefit from reduced temperatures will be an application for an infrared reflective coating.

Solvent- and Water-Based Formulas

There are colorants containing infrared-reflective materials with both solvent and water-based formulas designed for broad compatibility in coatings. An example of a solvent-based IR-reflective colorant is the Spartacryl PM® Series, which has been formulated to provide a universal colorant system to the coatings formulator for tinting and full pigmentation of most solvent-based industrial coatings. There is also a low-VOC solvent-based line called Chroma-Chem® 846. These pigments provide broad color space, excellent durability, lightfastness and chemical resistance, and are dispersed in a unique, proprietary acrylic resin vehicle that provides excellent wetting and dispersing properties. The solvents used are a variable blend of proprietary esters and propylene glycol monomethyl ether (PM) acetate.

Some examples of water-based IR-reflective colorants are the Chroma-Chem 50-990 Series and 897 line. The former are low-VOC pigment dispersions consisting of pigments finely milled in a blend of water, additives and a unique low-VOC binder. This package produces colorants with compatibility in a wide range of water-based chemistries. To better meet current VOC regulations, these colorants do not contain any added VOCs and are glycol free. The 897 products are high-strength, low-VOC colorants designed for use in a wide variety of water-based industrial coatings. The pigments provide excellent durability, light fastness, chemical resistance and are APE free.

For more information, visit www.chromaflo.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!