Ebeam Technology: a 40-Year-Old Secret

figure 1

The BroadBeam™ LE Series electron beam system with patented Integrated Shield Roll is a very popular model and configuration for printers and package converters.

An example of the BroadBeam LE Series electron beam system equipped with a 4-in-1 configuration for package decoration.

Though ebeam technology has existed for over 40 years, there are still quite a few seasoned coatings professionals that are not aware of the effectiveness of ebeam curing and the value it holds over its competing technologies. Fortunately, however, the cat is slowly coming out of the bag: use of ebeam technology continues to be a growing topic among coaters, printers and package converters. Ebeam instantly dries – or more accurately, cures – ebeam-friendly inks, coatings and laminate adhesives onto paper, film, paperboard or metal. Those using ebeam have documented benefits that include superior product consistency, improved product performance, higher process throughput and greater energy savings.

How Ebeam Curing Works

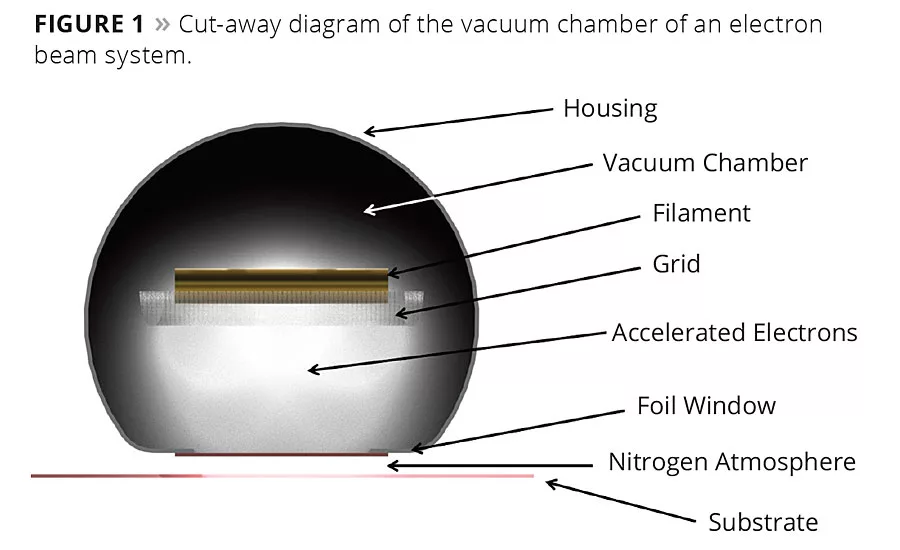

Figure 1 is a cut-away diagram of the vacuum chamber of an electron beam system. The ebeam curing/crosslinking process starts when an electrically charged filament – usually made of tungsten – generates clouds of electrons within an ebeam system’s vacuum chamber.

These electrons are then accelerated through a thin, metallic foil window onto the moving web surface. These accelerated electrons ionize most organic materials, which leads to the formation of free radicals. This reaction initiates polymerization of liquid polymer monomers and oligomers. The end result is instantaneously “drying” of an ink, paint, coating or adhesive (called curing); often with the added bonus of strengthening the impacted material (called crosslinking). Some applications result in both curing and crosslinking.

Ebeam curing continues to build momentum as a desirable alternative to both oven (thermal) drying, and ultraviolet (UV) curing for several reasons. In comparison to thermal drying, ebeam systems take up much less space than ovens, which can run hundreds of cubic feet in size in some instances. Converters replacing decades-old oven configurations with an ebeam system often find they have freed up more than enough floor space to put in a new line. Additionally, ebeam systems generate very little heat in the substrate being targeted. This makes ebeam a superior choice when using heat-sensitive materials like thin films (such as those found in shrink-sleeve labels) over thermal drying and UV curing.

Ovens require an enormous amount of energy, and older, less efficient systems can be painfully expensive to operate and maintain. In fact, studies exist that have shown that in some cases an ebeam system requires up to 95% less energy than the oven it replaces. Since their coating and ink formulations have no solvents to remove to effect drying, ebeam curing eliminates the potentially dangerous volatile organic compounds (VOCs) that are associated with thermal drying. Lacking solvents, ebeam inks and coatings require fewer shipping expenditures and take up less inventory space. Finally, companies replacing giant oven driers with virtually heat-free ebeam curing systems experience a much more comfortable work environment, especially in the summer months.

Specific to UV curing, ebeam curing also offers several significant but different advantages. In order for light-based UV curing to work, it requires photoinitiators to complete the curing process. Photoinitiators are toxic, and run a slight but nonetheless legitimate risk of migrating into food. Ebeam curing does not need photoinitiators to work, and as such poses no potential for migration. This makes ebeam curing an extremely desirable technology alternative for food package printers and converters, and other companies manufacturing products that are likely to come in contact with food.

Ebeam curing offers stronger penetration than UV curing and does a better job of curing thick, opaque and/or high-density ink and coating layers. Similar to thermal drying, UV curing produces a significant amount of heat; in certain cases ebeam curing has been shown to require up to 80% less energy than UV curing. Unlike UV bulbs, whose power declines over time, ebeam curing offers extremely precise processing, with a stable energy output that does not drift over time. Ebeam curing provides higher-gloss finishes, and, as an added bonus, because of its crosslinking effects, ebeam strengthens cured surfaces with additional scratch and scuff resistance properties.

New Horizons in Ebeam Applications

For much of its history as a coating and ink curing solution, web offset printing presses were the application of choice when incorporating ebeam. In recent years coating and ink formulations have also been developed for flexographic and gravure printing, as well as metal coat curing. Most recently, ebeam use in curing digital inkjet materials has produced significant interest and offers promise of growing rapidly.

Printers and package converters have also discovered that ebeam can be used not only for curing, but also as a useful tool to give extra ‘eye appeal’ to packaging. By adding a 4-in-1 converting line to an ebeam system, package converters can use electrons to create innovative package designs. Visual enhancements offered by an ebeam package decorating system include overprint coating, laminating, cold foil transfer and Cast & Cure™ holographic embossing.

Ebeam provides instant curing of coatings and adhesion of laminates to a packaging surface, providing a high gloss and inherent durability that is not possible with other curing technologies. Packagers take advantage of increased package brightness and strength capabilities to give products a new visual pop while reduce package abrasion and breakage risks.

With cold foil transfer, an ebeam-curable adhesive is applied to the substrate in registration with the desired printed graphics. Then the substrate is paired with a metalized film over its surface and ebeam cured. The metal transfers to the cured adhesive areas, producing a visually pleasing metallic visual. Nearly any type of hot or cold stamping foil can be used in an ebeam cold foil process.

Cast and Cure (Cork Industries, Inc.) is a decorative coating process that combines the “casting” of holographic images with the “curing” of the targeted coating. Similar to cold foil transfer, an ebeam-curable adhesive is put on a substrate in registration with the desired printed graphics. The substrate then comes in contact with a film containing the desired holograph and ebeam cured. Ebeam passes through the film and ‘freezes’ the image onto the adhesive areas as it cures them. It provides a consistent high-quality finish, and can generate ultrahigh gloss, matte and holographic images onto a variety of substrates. Casting film can also be reused numerous times for substantial cost savings.

Ebeam package decorating systems are designed for use with web-printed packaging materials, including flexible packaging, folding cartons, labels and multiwall bags. These systems work at high speeds, are compatible with wide web widths and generate low substrate heating, which is important when utilizing sensitive flexible packaging materials like thin films.

Conclusion

Ebeam systems have grown increasingly popular in the converting industry, both as an alternative to traditional curing methods and in a new role as a tool to produce innovative package decoration. Paint and coatings professionals who continue to contribute to the evolution of ebeam-friendly formulations and applications help bring light to this important but often secretive technology, and also equip their customers with new tools to save money, improve their production techniques and introduce new, differentiated products. Those willing to continue pushing the envelope in these areas promise to experience some very exciting times in the coming years.

To learn more about ebeam technology visit www.teampct.com .

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!