New Technology Helps to Accelerate Coatings Development

POTSDAM, Germany - Developing wall paints and varnishes presents a big challenge for manufacturers. One reason is that samples merely enable them to estimate what the dispersion behavior in the reaction container will be. By teaming up with PDW Analytics GmbH, Fraunhofer researchers are now for the first time able to monitor the production of paints, varnishes and adhesives continuously and in real time – allowing them to design more efficient processes.

Not all wall paints are the same – anyone who has ever tried to paint over a colored wall using cheap white paint can tell you that. While high-quality, expensive paints have excellent coverage, bargain products allow the old, colored coat of paint to shimmer through. Application, drying properties and gloss finish differ enormously. The material properties of wall paint depend to a large extent on the size of the particles it contains – for example filler material, bonding agents, pigments or additives. That is why, when developing new paints, manufacturers want to know precisely what goes on in the reaction containers and how the sizes of the particles change during the process. Normally, manufacturers take a sample of the paint, thin it down and analyze it. This is very time-consuming; not only can the properties of the manufactured wall paint change during this time, but the act of thinning can also affect the sample. For instance, smaller particles may clump together to form larger particles. Consequently, the particle size in the sample will not necessarily be the same as that in the reaction container.

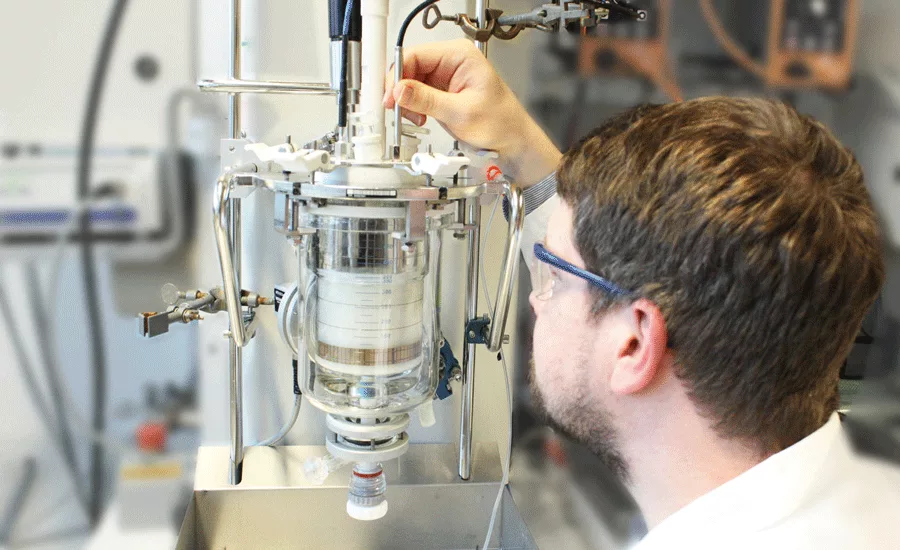

In the future this process will be simpler, quicker and more precise: for the first time manufacturers will be able to analyze wall paints, varnishes or even adhesives inline. In other words they will no longer need to take samples, but can analyze their product continuously and in real time directly during the manufacturing process. This is made possible by a new sensor that has been developed by the staff of the Potsdam-based company PDW Analytics GmbH, and integrated by the researchers from the Fraunhofer Institute for Applied Polymer Research IAP into their existing process development system. “This is a globally unique process-analytical detection method that allows key parameters in the manufacture of paints, varnishes and adhesives to be continuously monitored in real time,” says Dr. Antje Lieske, head of department at Fraunhofer IAP. “This helps us to get a much better understanding of processes, design them more efficiently and avoid production failures.”

At the heart of this technology is a sensor based on photon density wave spectroscopy – a process developed by PDW Analytics. This sensor works by radiating laser light into the liquid wall paint via optical fibers. The intensity of the light is modulated up to the gigahertz range. Next, the method analyzes how – depending on the frequency – the light propagates in the liquid. From these data the size of the individual particles is determined. The researchers at the IAP have developed reference systems by using the photon density wave spectroscopy technique to measure various samples with particles of a given size.

The IAP researchers use the sensor to reconstruct and analyze production processes for their customers. “We interface this novel sensor with our existing system as well as with our expertise,” Lieske explains. For some time now, the scientists have been working with a process development station that, in the case of suspensions with particle sizes of between one micrometer and one millimeter enabled them to determine not only viscosity and heat flow but also the particle sizes. An infrared sensor additionally detected the chemical changes and showed to what extent the chemical reactions have advanced. “With this new sensor, we can now also measure particle size across the entire relevant size range from nanometer to micrometer,” Lieske adds.

Customers can opt to have their processes analyzed at the IAP, for example in the case of issues a company is unable to resolve itself. Alternatively, because the whole system is transportable, they can use it on site at the company’s premises. Typical questions are: Can polymerization time be reduced? How can uncertainties in the process be eliminated and material properties improved – for example, how to ensure that adhesives adhere better or wall paint covers better?

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?height=200&t=1745333386&width=200)