A Viable and Sustainable Alternative to Dioctyl Sebacate Plasticizer

Emery Oleochemicals’ ozone reactor plant in Cincinnati, Ohio.

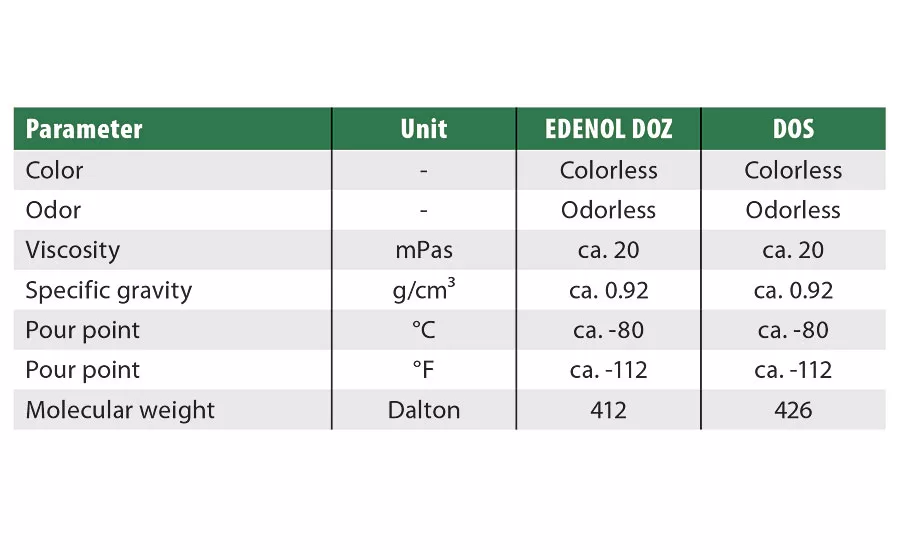

TABLE 1 » Physicochemical properties of EDENOL DOZ and DOS.

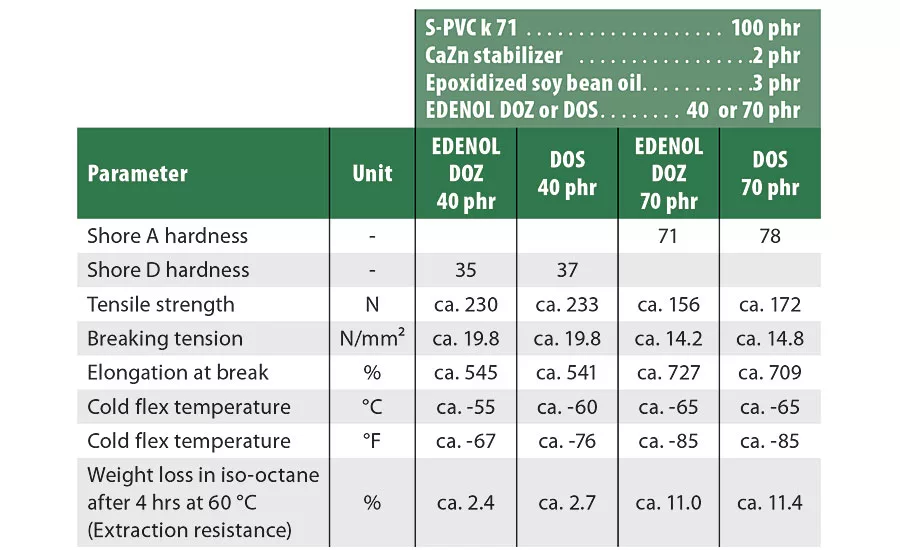

TABLE 2 » Properties of PVC plasticized with EDENOL DOZ or DOS.

In the coatings industry, soft PVC is mainly used to coat truck tarpaulins, marquees, floor coverings and as metal coatings. While dioctyl sebacate (di(2-ethylhexyl) sebacate, or DOS) is a widely used plasticizer, it has become more challenging for companies to acquire sebacic acid-based plasticizers like DOS due to increasing costs, along with the uncertainty and lack of stable supply of sebacic acid. EDENOL® DOZ is a new plasticizer able to replace DOS in developing most soft PVC coatings.

The Uncertainty of Sebacic Acid Supply

Sebacic acid, also known as decanedioic acid, is a useful building block for plasticizers and polymers. The most well-known polymer derived from sebacic acid is polyamide (PA 6.10). Sebacic acid is produced on an industrial scale mainly from castor oil, which is a biobased raw material. Therefore, products made from sebacic acid can be labeled as partially or fully biobased depending upon the other ingredients in the end-product formulation.

The production capacities of sebacic acid from castor oil are mainly located in China and India. In December 2016, the Chinese government ordered a shutdown of factories in northeast China, with the target to reduce the heavy air pollution in that region.1 As several plants producing sebacic acid were affected by this measure, this shutdown was followed by a series of force majeure declarations on sebacic acid. With the restrictions on air pollution becoming even stricter in the future, this situation most likely will occur again during the next Chinese winter season.

Impact on Dioctyl Sebacate Plasticizer

One of the products derived from sebacic acid that was heavily affected by the force majeure is the widely used plasticizer, DOS. DOS, an odorless and colorless liquid with low viscosity, is generated by reacting sebacic acid with 2-ethyl hexanol. DOS is food contact compliant according to FDA CFR 21. It has become an industry standard as a low-temperature plasticizer for PVC coatings due to its low volatility and good weathering properties.

However, because of these supply challenges, the PVC industry is in need of a technically equivalent plasticizer to DOS from a secure supply chain. The alternative should also be FDA food contact compliant and at least partially biobased to meet market needs.

Readily Available Azelaic Acid Alternative

Azelaic acid, also known as nonanedioic acid, is a viable substitute for sebacic acid as it differs only slightly in chemical structure. Emery Oleochemicals was the pioneer in the commercial development of azelaic acid over 60 years ago.2 Emery’s integrated manufacturing processes and readily available feedstock of azelaic acid through its proprietary ozonolysis process ensures a secure supply to the market.

Starting from natural oils and fats, the company produces oleic acid, among other oleochemicals. This oleic acid is then fed into Emery’s proprietary ozonolysis process, which cleaves the oleic acid with ozone based on natural oxygen. The cleaved products are azelaic acid and pelargonic acid, which are then further purified.

A New Alternative

A new alternative to DOS, EDENOL DOZ is di(2-ethyl hexyl), or dioctyl azelate, which provides the following benefits:

- food contact compliance according to FDA CFR 21;

- partially biobased material, with azelaic acid derived from natural sources;

- same, or very similar, application characteristics in PVC compared to DOS, which is outlined later in this article; and

- security of supply: the production process is back-integrated, beginning with conversion of natural fats and oils feedstock into oleic acid, production of azelaic acid by ozonolysis, and finally, synthesis of the ester EDENOL DOZ.

Comparison of EDENOL DOZ and DOS

As azelaic acid is a close homologue of sebacic acid, the respective esters are very similar in their product properties. As shown in Table 1, viscosity and specific gravity are the same. Thus, when switching from DOS to EDENOL DOZ, little to nothing needs to be changed in the dosing system.

Since the chemical structure and physicochemical properties of EDENOL DOZ and DOS are very similar, the behavior of both plasticizers in a PVC formulation was compared. A basic PVC formulation was used: a CaZn-stabilized PVC with epoxidized soy bean oil as co-stabilizer and the plasticizers, EDENOL DOZ or DOS, at two respective dosage levels of 40 or 70 phr (Table 2).

Comparing EDENOL DOZ and DOS, one can recognize the deviations are quite small and often within, or close to, the tolerances of the respective measurement. The Shore hardness tends to be slightly lower with EDENOL DOZ compared to DOS; therefore, the plasticizer dosage in this formulation could have been reduced when switching from DOS to EDENOL DOZ. With the tensile strength at 40 phr dosage being the same for both plasticizers, the difference at the higher dosage is minimal. Breaking tension, elongation at break and the cold flex temperature do not show any significant differences. The extraction resistance to iso-octane shows a small advantage for EDENOL DOZ within the accuracy of the measurement. Although the differences in behavior depend upon the full formulation used, EDENOL DOZ is certainly the closest alternative to DOS that is available in the market.

Conclusion

EDENOL DOZ provides similar properties to DOS in substance as well as incorporated in PVC. Both plasticizers provide food contact compliance according to FDA CFR 21 and both are partially biobased materials. However, while DOS is dependent upon the supply chain of castor oil and sebacic acid, the new plasticizer is based on azelaic acid, which is derived from a reliable and proven process of ozonolysis of oleic acid. Oleic acid is sourced from numerous natural fats and oils, so EDENOL DOZ provides the highest level of safety of supply for the PVC industry, and therefore, it represents a viable and sustainable replacement for DOS.

For more information, contact gp.americas@emeryoleo.com or gp.europe@emeryoleo.com, or visit http://greenpolymeradditives.emeryoleo.com/additives/.

References

1 http://www.chemceed.com/tag/sebacic-acid/

2 https://www.google.com/patents/US2813113

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!