DYNAFLOW INC. Adds to Materials Testing Capabilities

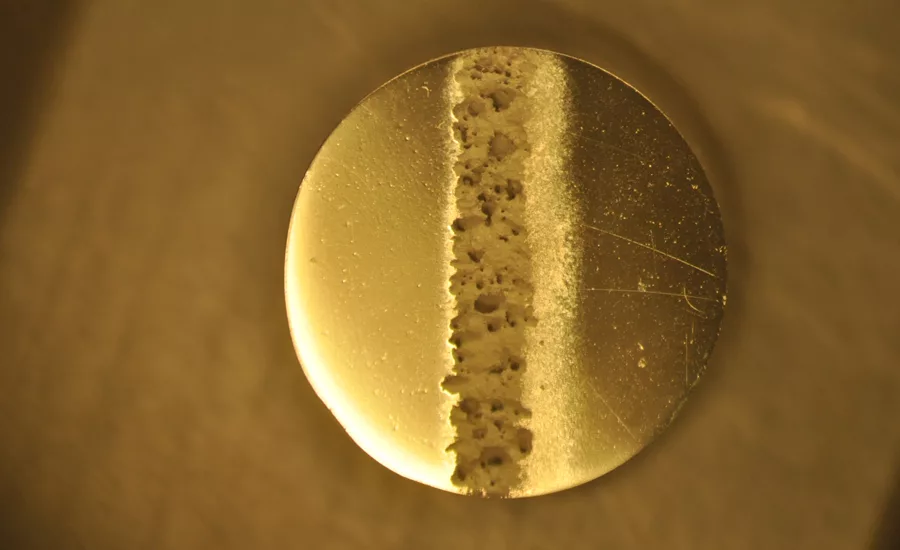

JESSUP, MD — DYNAFLOW INC. announced additions to its specialized materials testing capabilities. To further its capabilities to test the resistance of materials to cavitation and liquid impact, a new test rig allows for testing of resistance to micro-solid particle impact. The facilities allow the study of the properties of materials undergoing rapid loading and help engineers select the most resistant material or coating formulators improve their coating.

DYNAFLOW INC. conducts standard (ASTM G32, G73, G76, G134) tests as well as customized erosion tests for cavitation, liquid droplet, slurry, and solid particle impact, using ultrasonic excitation, high-pressure air and water jets, and whirling disk devices. The various test loops can accommodate a wide range of erosion intensities with water-jet pump pressures varying from tens of psi’s to 40,000 psi. DYNAFLOW also conducts split Hopkinson pressure bar tests to measure materials properties at high rates of strain (~5,000/s). For additional information, call 301/604.368 or e-mail info@dynaflow-inc.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

-(1).webp?height=200&t=1668413861&width=200)