Digitize to Optimize

Case Study: the Future of R&D Through an Outsourced, Cloud-Based Data Platform

The paint and coatings industry functions in a manner that has been in place for decades. If it’s going well enough, and the industry is certainly thriving, is there a good reason to seek for ways to optimize? Going on the principle that optimization is, by definition, a step forward, recent studies were undertaken that demonstrate that there is a new way to keep the industry just as effective, if not more so, while streamlining the R&D process, while saving both money and materials and better using one’s staff. The key is digitizing research and development. This begins with using an independent, cloud-based technical enabler platform that combines a raw materials database with a “virtual lab” in which researchers can experiment virtually, before stepping into the actual lab. This dramatic new modus operandi is already available and is being used by leading firms.

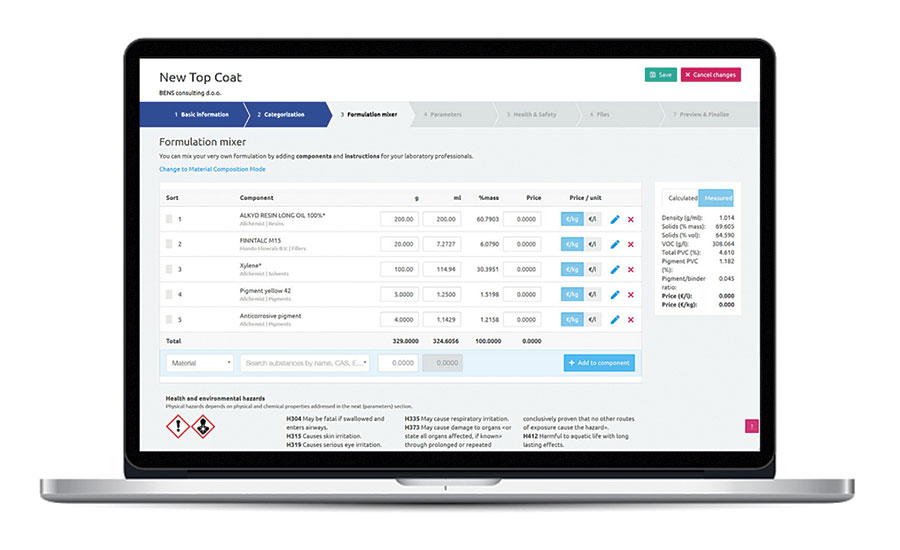

This article examines these new study results. The key shift is away from an old-fashioned approach, which is weighed down by repetitive manual labor and administrative work. Instead, the better way forward is the more modern solution of outsourcing data input and formulation experimentation to a cloud-based ICT (information-communication technology), which we will call a “technical enabler:” third-party software kept up-to-date with complete, usable data and safety information on thousands of raw materials. This database needs to be integrated into an application that allows for “virtual experimentation,” which helps to narrow the number of actual, full-scale laboratory experiments needed to bring the right new product from concept to market, dramatically reducing non-value-added work. The study in question used such a technical enabler, called Allchemist, to test both its efficacy and the result that switching to such an option would have on paint and coatings R&D departments.

The Problem

Data input is a necessary, but unwanted task for R&D departments. Technical and safety sheets, normally sent out either as papers or PDFs, are unwieldy and require a lot of data entry and constant updating. This is often done by Ph.D.s who are eating up a lot of their time typing into spreadsheets, when they could provide far more benefit to their firms by using their talents to research and develop. Technical enabler software streamlines these time- and energy-consuming steps by outsourcing them, eliminating the need for data and safety information to be requested, gathered, entered and manually checked by R&D staff. In turn, this frees researchers to do what they do best and for what they are paid - to develop new products.

Thus, the data entry component of the problem is removed through outsourcing, and the result is a technical enabler data platform that offers complete and up-to-date safety and technical information on thousands of raw materials. Then comes the second step in the streamlining process. The information in the technical enabler allows for “virtual experimentation,” with issues such as hazards in mixing certain raw materials, price points, etc., calculated “live” within the software. This allows the software to raise potential red flags for the researcher, without actually stepping into the lab and using up time and materials unnecessarily.

This is key, because once calculations are made and a variety of formulations are prepared, they are tested in the laboratory, creating the product and its variations until what appears to be the optimal solution is reached. However, the first (or indeed the first few) variations on this formulation rarely satisfy all departments and come to market. New formulations will be sent to marketing, safety and other departments, and it is often the case that the formulation will not satisfy these other departments, and so R&D must “go back to the drawing board” and come up with a variation. The two most frequent stumbling points in developing new products - safety issues and price points that are incompatible with the estimates of marketing departments - can be eliminated or reduced through virtual experimentation.

A technical enabler that combines an outsourced data platform with a built-in “virtual lab” can save much of this. It can be used to virtually experiment with new formulations for products, thereby catching potential issues, like hazards and price points, early on, in the virtual stage, saving time, money and materials by requiring fewer complete lab experiments and thus fewer back-and-forth between various departments.

Until now, there has been no other viable option. R&D departments continue to push on, functioning and producing, certainly, but with significantly less efficiency, and with greater expense, because there is so much non-value-added time at play in this current system.

Can technical enabler software make a strong, positive difference?

Case Study in Practice

A 2018 study undertaken in Slovenia (accepted for publication but as yet unpublished) used a new technical enabler platform called Allchemist that matches the aforementioned characteristics, in order to test relative efficiencies in the experience of coatings formulators. The formulators participating in the study first used the traditional system, which was divided into two steps, data acquisition and formulation. They then modeled what the process would look like using the technical enabler.1 Formulators from three different companies, each of a different size, were involved in the research.

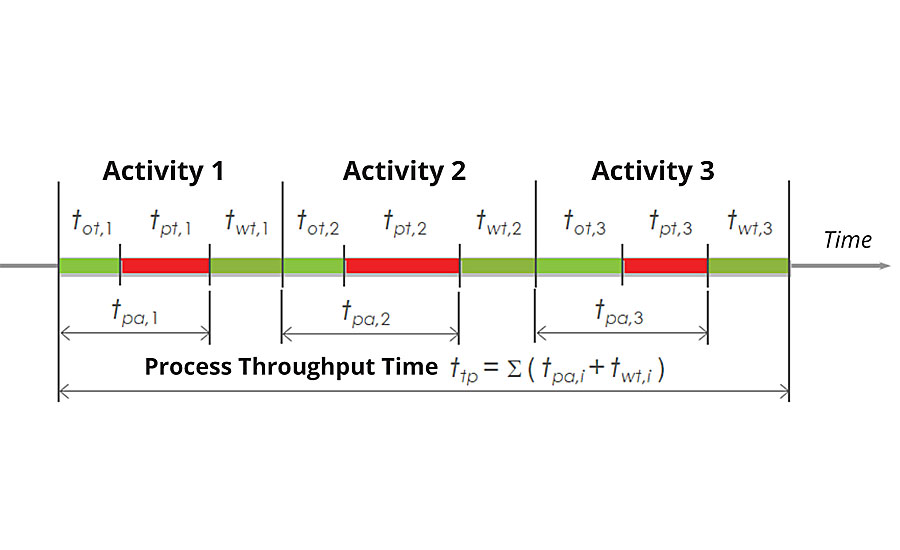

This project divided the execution of all R&D activities into a timeline: waiting time (twt), orientation time (tot) and processing time (tpt). Combining these categories resulted in total activity throughput time (Figure 1).

Product development was subdivided into the following: creating a new product idea, marketing analysis of existing products, searching for suitable binders, study of binder properties, searching for pigments, searching for additives, searching for solvents, searching for fillers, formulation (modified) formulations, ordering samples, product laboratory testing, product parameters measurement, product hazard identification, product price calculating, internal validation, external validation, preparation of documentation draft and creating documentation.

For each category, the researchers asked the three companies in the study to predict the expected time, optimistic time, most probable time and pessimistic time for completing the phase in question. Phases such as “waiting time after activity” are often overlooked but are crucial to the overall timeline. Not only active time, but waiting time between actions is an aspect of the process: for instance, if results are sent to a colleague, then one must wait until the colleague receives the results, takes the time to examine them, writes up a response and sends the response back. What may map out as, say, seven hours of total work to complete a project may be seven hours of active work, but when one integrates delays and waiting between actions, then seven hours can easily transform into seven days or seven weeks.

In this study, 18 different activities were tested via both static and dynamic process testing at three companies of varying size, all in the paint and coatings field and all based in Europe.2 Simulations were carried out over 231 days, eight hours a day - the total number of working days and hours in one calendar year. Each company functioned as an independent case study, with the researchers asking R&D department employees at each company to keep track of the time they took to complete research and development activities using the traditional methods employed by each company, and then while using an outsourced, cloud-based technical enabler application.3 This data was sent to the researchers for analysis.

Data Acquisition

In lieu of the traditional method of data acquisition, requesting data on raw materials from chemical producers, receiving it in PDF form and inputting the data into in-house software, this study asked the companies involved to estimate what a timeline for development would look like if they used a technical enabler, in the form of an independently run, cloud-based application. This application already contained data, pricing and safety information on over 2,000 of the most-frequently-used raw materials in the coatings industry, and this was updated on a regular basis by dedicated, trained staff, keeping tabs on new information about existing products (such as changes in properties or parameters), and also adding new raw materials to this ever-expanding database.

The result of this predictive modeling approach to how the companies’ operational procedure would play out using such an application was that the companies involved in this study did not need to dedicate a single moment to data entry and acquisition. None of the companies involved in the study needed access to data on raw materials that were not already in the technical enabler’s database. They had access to the technical enabler’s application and just logged on.

Lab Formulation and Testing

Laboratory testing is the most cumbersome of all the necessary activities among the processes in coatings research and development. Yet it is an essential step, as lab results are essential to new product launches. The key is to locate weak points in the formulation and testing process, to see if aspects can be streamlined or eliminated, in order to improve the overall process of bringing new products to light.

The research noted that unnecessary laboratory tests could be greatly reduced, if not largely eliminated. Functionality testing (for instance, is a new paint the right consistency) is necessary, but other details (hazards, environmental friendliness, pricing) could be determined in a virtual environment. By working in a “virtual formulator” that was part of the technical enabler’s application, companies were able avoid lab tests that they could already tell were not going to produce the end result that was required (Figure 2). Paint and coatings companies are used to running numerous lab tests, only to come up with one that produces the desired result and opens up a new product. R&D staff must have access to a functioning, programmed, software-enabled database, as opposed to the passive spreadsheets employed by most companies to keep track of raw material data, in order to be confident using a virtual formulator. They need a broad database that is usable (read as: not in PDF or Excel formats), in which they can experiment virtually.

Experimenting using a virtual formulator funnels out the lab tests that need to be done physically. One begins with many different ideas of how to solve a problem and come up with a new product. Rather than seeing out complete lab testing of many of these ideas, formulations were mapped out in the virtual formulator, and those without maximum promise are eliminated. This software kept regular track of the total cost of the raw materials going into the recipe and highlighted any hazardous interactions of selected materials and environmental warnings. This meant that, within the confines of the virtual formulator, R&D staff could experiment with different formulations and see which would not work from a pricing, hazards and environmental perspective. This process does not eliminate lab tests, but fewer lab tests were run, and those that were run had a greater likelihood of being useful, leading to an end product.

Conclusion of the Case Study

Though the scale of this study was small, it showed dramatic results in companies of a variety of sizes, providing optimism for this new approach to coatings R&D, and paving the way for new, more expansive studies. Results show a 47% reduction in the R&D process throughput time for a newly developed product. There was also a 70% shorter throughput time for the execution of R&D activities for which the technical enabler had a clear, direct result (such as in the virtual formulation experimentation). Surprisingly, there was a 7% reduction in throughput time for activities for which the technical enabler did not have a clear, direct role, for example in the actual lab testing. This suggests that this streamlined approach not only speeds up the process at the obvious points, but also results in what might be called a “streamlining culture” that positively benefits all aspects of the R&D process, even those not directly involving the technical enabler application.

References

1 “Research into Digital Transformation Eligibility in the Field of Paints and Coatings Development.” University of Maribor, Faculty of Organizational Sciences, Laboratory of Enterprise Engineering, 2018.

2 It should be acknowledged that this is a small test range, but one has to begin somewhere, and the availability of technical enabler software solutions is new enough that this represents the very first viable study and features such superlative results that it will surely inspire many future studies.

3 The technical enabler application used by the study in question was Allchemist, a prototype developed by Bens Consulting d.o.o. More information is available at www.allchemist.net/.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!