The Key to Expert Color Matching

As the largest Sherwin-Williams Aerospace distributor, one of the best ways that Blend Supply serves industry partners is through custom color matching. Christopher Cummings, Master Color Matcher, is in charge of all color matches, and fields all color application questions. He describes his process in this article.

How the Process Works

It all depends on how it starts. Requests come in differently. If it comes with the sample, i.e. a wet sample or spray out, we start with that. A request may be sent in asking about a Sherwin-Williams Aerospace standard color that they want matched in another line. They may request a federal standard color that is not already ready in our system, so I have to create the match.

If it's a panel of a plane or spray-out, I look at the CCR (Custom Color Request) to see what the guidelines or comments are. The customer may want something specific. They may want a 4" x 6" panel matched in Acryglo, for example.

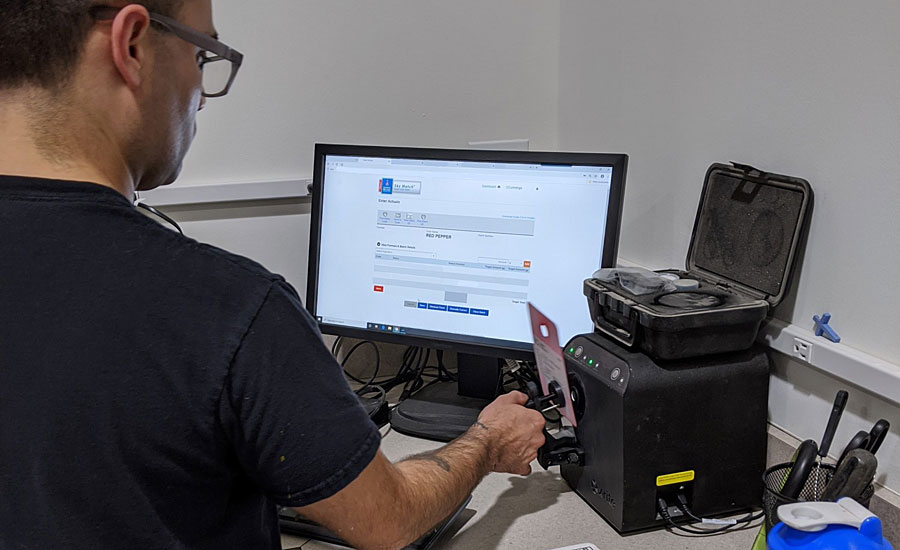

Not every match can be matched on the spectrometer. If it's a pearl or metallic color, it's by eye. If it is simple, I just run it through the spectrometer and I see what it's reading and the formula it gives me. I gauge what formula is the best. I then choose the formula and print out the recipe.

Bringing the Color to Life

I mix the first batch. This is a test batch to see where it is at. I then spray it out and go from there.

I look at the color and see if it's good. I usually have to tweak what the spectrometer gives me. Once I get to where I think it is good, I get visual spectrometer readings. I may need to use the gloss meter to check that it is right. I check the metamerisms. I have to make sure it looks good at all angles. It's possible the color will look right, but only under a certain lighting. I need good readings electronically and visually.

The other day I got a black sample that was faded, with white stuff on it. I discussed it with another Blend team member and went from there. I sent two samples to the customer to see what they liked best, and they approved one of them.

The Challenges

The most difficult part is when I am asked to match a military color. These colors go a long way, so you have to be very exact. There is no wiggle room if you get something wrong. Pearls and metallics are also tough. The best way to succeed there is to find something that's been done before and base it out of that.

A lot of people do not understand the complexity of our color matching operations. You have to really understand the colors and the customer. I'm not just mixing colors. Every day I'm talking to the customer or Blend rep and trying to gauge what the customer is really looking for. Now understand, I came from a wood finishing background. I had to really learn all of the components involved in Sherwin's process, hardeners for example. I spend lots of time building my knowledge of how they all work together.

Another challenging aspect of this role is that it isn't something that people can just pick up and do. A lot of people don't have great color vision or the patience required. If I could quickly train more people to do what I do, I could greatly increase our efficiency. Just handing a metallic match to someone and having them return the right product to you can take time to develop. Growing our Color Matching Team is taking a lot of time and effort.

For more information, visit www.blendsupply.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!