Understanding and Achieving Digital Transformation

A five-step plan for successful, ongoing digital transformation

“So when are we going to get started implementing all this digital transformation stuff,” Jack jokingly asked Mike one day. Responding in kind, Mike said, “As soon as we figure out what it is and where to start!”

Jack and Mike owned Summit Manufacturing, a successful mid-market manufacturing company. In the current environment, Summit faced challenges with customers, markets and within their own company (Figure 1). But where others saw problems, Jack and Mike saw opportunities.

It was hard to pick up a trade magazine or follow a site on the internet without hearing about digital transformation as the wave of the future. Jack and Mike thought there was opportunity there but wanted to make sure they understood how to reap the benefits for Summit Manufacturing, while avoiding the pitfalls many of their colleagues had encountered. Stories were rife about finding some “hot” technology, trying to get it in place, finding out it didn’t connect among all the parts of the business needed, and losing support in the company. At one company, employees revolted against a poorly planned implementation so heavily the company was forced to return to the old “green screen” technology they previously had in place.

Defining Digital

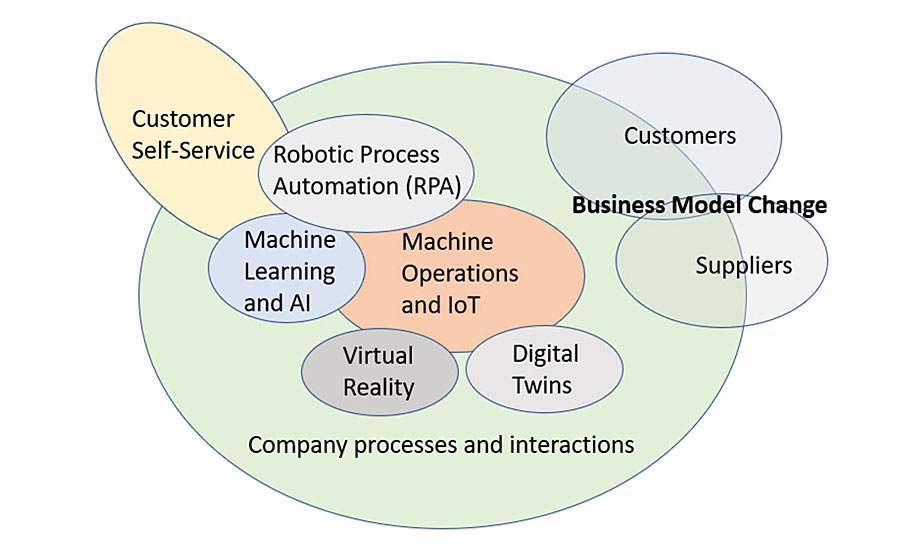

Looking deeper into the topic revealed a multitude of terms and meanings for digital transformation, including the Internet of Things (IoT), Industry 4.0, virtual reality, digital twins, robotic process automation, smart applications, machine learning and artificial intelligence. It was clear that digital transformation by itself was a generic term for many different concepts (Figure 2).

What didn’t appear in all the articles was the business objectives companies had that may include a focus on customer interaction, internal processes, machine operations, and/or actions to reduce downtime or improve outputs. Digital transformation could even include a complete change in the business model and establishing new ways to work with customers and suppliers.

It was clear to Jack and Mike they needed to first set out clear objectives on what they wanted to accomplish with digital transformation, to guide their efforts and those of their managers and employees

Use of Data

After much discussion with the team, Jack and Mike concluded that digital data was the only common element among all the “digital transformation” concepts. Many of these concepts promised a flood of new data that would somehow enable better decisions and make the business work better.

Jack and Mike concluded that before committing to generating significantly more data, they needed to better understand their current data collection, analysis and usage. What they found was not encouraging.

- Data quality was poor. Information in the ERP system was inaccurate and inconsistent, leading employees to develop their own systems at a further cost of productivity and accuracy.

- The company was using an abundance of Excel files, with each one dedicated to a local purpose and not linked to other data.

- The company was collecting data, losing it, then trying to find it again at another point in the process. The excessive number of Excel files, and, for example, using different names for the same data, were clearly factors preventing data flow and accessibility.

- Old “rules of thumb” (tribal knowledge) was driving many activities. Important knowledge wasn’t incorporated in decision making, which created resistance to change, increased the risk to the business of employee turnover, and made it harder to make new employees productive quickly.

- Existing data had no clear ownership in terms of who was requesting the information and what the plan was for collecting, maintaining and acting on the data.

The metrics they did have measured activities, but not outcomes; they did not link to the underlying process, yielding ambiguous results; and they did not allow people to connect their actions to the results.

Understanding Processes

Understanding how data was captured and used in Summit produced an interesting revelation. Jack and Mike thought their processes were clearly defined. But as they and their managers looked deeper, they found that many processes worked the way they thought (and according to the documentation) for about 80% of the cases. In the other 20% of the cases, ad hoc or tribal-knowledge-based processes had to be used to achieve the desired result. Employees were spending 80% of their time resolving issues in the “20% cases.” In addition to the time and money lost, this was de-motivating for employees.

One take-away from that discovery was that adding a layer of technology on processes that weren’t fully understood would not be effective. Another was that this situation made it difficult to establish reliable and meaningful metrics and contributed to the proliferation of Excel files and reliance on tribal knowledge they found.

Jack and Mike also saw that Summit was wasting a lot of time and money. As they discussed what this meant for pursuing a digital transformation, they reached an interesting insight. Working with employees and developing a deep, end-to-end understanding of their processes, and acting on the results, would engage their employees, develop their buy-in to change, eliminate the waste of time and money — and provide funding, which could be used for digital transformation.

Going Digital

From their experience, Jack and Mike saw that digital transformation involved a lot more than buying technology. They concluded that setting a clear direction on the business objectives for applying digital transformation was essential, as was understanding their processes and identifying which data would help them better run the business. Only then could they decide on the necessary technology to provide what the team needed to improve the business.

Jack, Mike, and the rest of the team came up with a five-step strategy for digital transformation.

- Define clear business objectives.

- Engage the people closest to the work to ensure they have a deep (and common) end-to-end understanding of the processes involved in achieving those business objectives.

- Establish the data that the team will use to monitor and support the achievement of those objectives.

- Examine the source and quality of the data.

- Identify the technologies that will support achieving these results.

Surprisingly, technology was the “last thing they needed” for digital transformation.

Jack and Mike understood that technology would continue to develop, providing new capabilities. This meant that they couldn’t view digital transformation as a one-time event. They needed everyone in the business to think about digital transformation as an ongoing process, integral to the changes in the business to improve productivity, create an environment to attract and keep employees, and improve their position in the market.

Implementation Experience

In their eagerness to achieve results, in the first project the managers jumped over the second step (engaging people closest to the work), believing that they already had enough understanding of the process. They lacked buy-in and found that the product would not support the processes as they actually worked. As a result, the effort fell apart.

For the next project, the managers included step two and engaged the people closest to the work to help identify and resolve issues that were causing loss of money and time. The savings from resolving these issues turned out to be a significant source of funding for technology solutions that would further accelerate improvement.

As the team resolved these issues, the right metrics became apparent, data quality markedly improved, and they were able to establish clear links between data analysis, actions to take and the improved results achieved.

*A version of this article first appeared in Moldmaking Technology, May 2020. Reprinted with permission from Gardner Business Media, MoldMaking Technology May 2020©.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!