Monitoring Thermal Coating Process for Quality Control

Bluetooth Loggers Ensure Coating Operation Remains in Specification

A thermal coating provider needed to monitor its thermal coating process to make sure the conditions were within process specifications for the material being applied. In particular, the customer needed to record air temperature, surface temperature, relative humidity and dew point. It was critically important to make sure that the surface temperature was at least 5 degrees above the dew point as recommended by ASTM Standard D3276 and ISO Standard 8502-4. It was also important to make sure that the air temperature was within the recommended application range as prescribed by the coatings manufacturer.

Installation

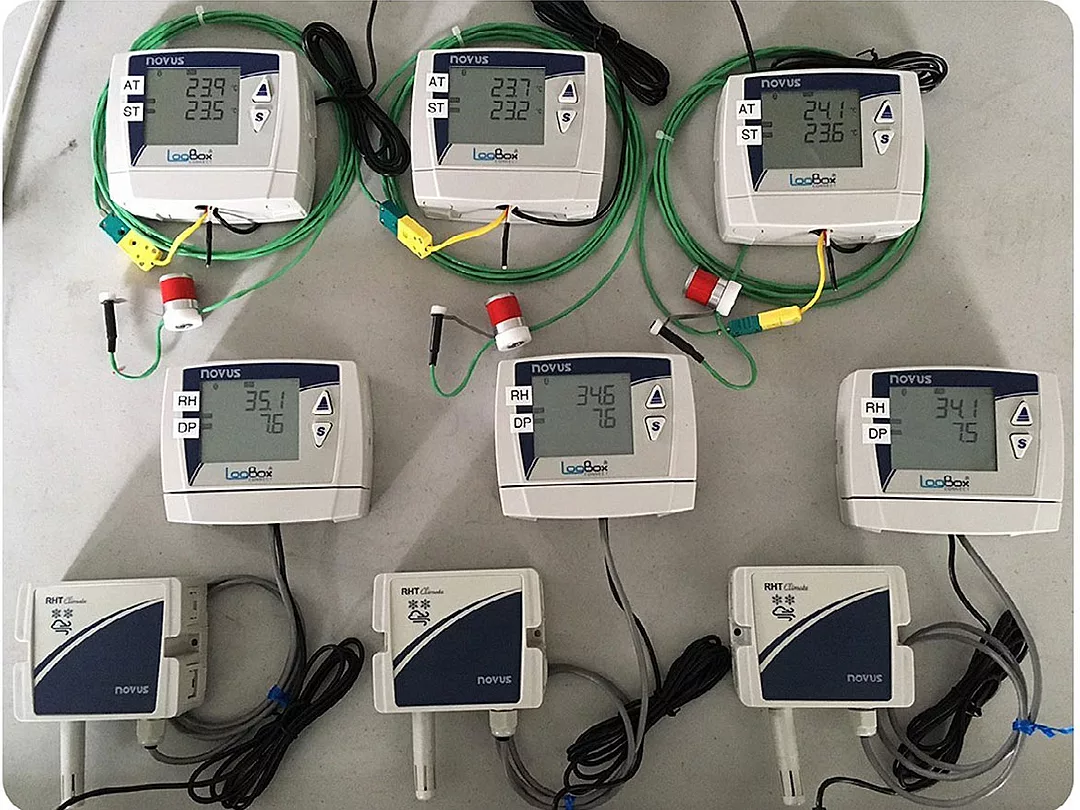

To meet their needs, CAS designed a system around the Novus LogBox BLE bluetooth data loggers. One set of loggers was outfitted with a PT100 RTD sensor to monitor the ambient air temperature and a magnetic mount type K thermocouple probe to monitor the surface temperature. A second set of loggers was used in conjunction with the Novus RHT Climate temperature and relative humidity transmitters to record humidity and dew point.

The analog signals are fed back to the Logbox data logger where the signals are then measured, properly scaled, displayed and recorded, providing immediate feedback as to the current conditions and an electronic record.

Usage

In this application, the magnetic surface temperature probe of the temperature data logger is attached to the part that is being prepared to be coated. The display of the logger shows both the ambient air temperature and the part temperature so that the operator can be sure both of these are within the acceptable range specified by the coatings manufacturer. For example, many types of coatings should only be applied if the temperature is between 50° and 90 °F. The logger attached to the RHT sensor displays the humidity and dew point. Again, many coatings suppliers recommend that RH be less than 90%. Finally, by comparing the dew point and the surface temperature, the operator can ensure that the substrate temperature is at least 5 °F above the dew point.

To meet the documentation requirements for quality control, the temperature, relative humidity and dew point are recorded at 5-minute intervals by the Logbox data loggers. All of these time-stamped values can be easily downloaded, graphed and, if necessary, printed out to provide documentation for quality control that the conditions were within an acceptable range when the coatings were applied. A useful feature of the LogBox BLE logger is the ability to quickly download and display data on a smart device like a cell phone or tablet using the Bluetooth interface with the NXperience app.

Benefits

Prior to the use of the data loggers, the customer used a manual system consisting of a handheld electronic thermometer with a thermocouple probe and humidity indicator. This required the operator to read the temperature and humidity, look up the dew point from a chart, and then record the temperatures, humidity and dew point manually on a form. As opposed to the written records, the new system was much easier to use and provided more accurate data.

Also, it provided data during the entire coating operation, whereas before they would record the data at the beginning and end of the process, and hope that everything remained stable in between. With the new system, the data could be downloaded at the end of the run and printed out in a graph, providing their customers hard copy proof that the conditions during the entire process were satisfactory.

For more information on Novus LogBox BLE data loggers, or to find the ideal solution for your application-specific needs, contact a CAS DataLogger Application Specialist at (800) 956-4437 or visit www.DataLoggerInc.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!