Co-Blending Phosphate Inhibitors for Sustainable, Low-Cost Corrosion Control

As professionals working within the coatings industry, we are all acutely aware of the issues that corrosion poses and want to provide our customers and end users with the best quality products to tackle this $2.2-trillion global issue.1 Anti-corrosion coatings have become a necessity for industries to safeguard the huge investments they make in terms of money, property and safety of workers. Whether coating to protect pipelines, airplanes or computer gadgets – customers are united in their battle against corrosion!

Historically, some of the most effective corrosion inhibitors have been based on chromium. However, these chemistries are currently being phased out globally – leaving a gap in the market for a highly effective inhibitor that is non-toxic and non-carcinogenic.

Following strong R&D efforts and lengthy extended testing, many coatings companies have turned to phosphate-based systems. This article highlights a step-change alternative that can save 10-30% on the cost of anti-corrosives as well as offering customers more sustainable coatings that require no hazard warning label.

Why Phosphates are Popular

Currently, 45% of the corrosion inhibitor market is dominated by phosphates. Industry testing and academic research show that adding zinc phosphate can inhibit the anode process of metal corrosion and consequently prevent the horizontal diffusion of the corrosive medium into the coating/metal interface and slow down the disbonding of the coating.2

Additionally, phosphates don’t pose the same health and environmental hazards as chromates, however, they do still present environmental issues through leaching. In its form as an inhibitor – it is classed as a Category 1 Environmental Hazard. Within the coatings system, at loadings of 2.5% and above, the paint will be classed as a Category 2 Environmental Hazard so will still require hazard labelling.3

Innovative and Trusted Technology Working Together

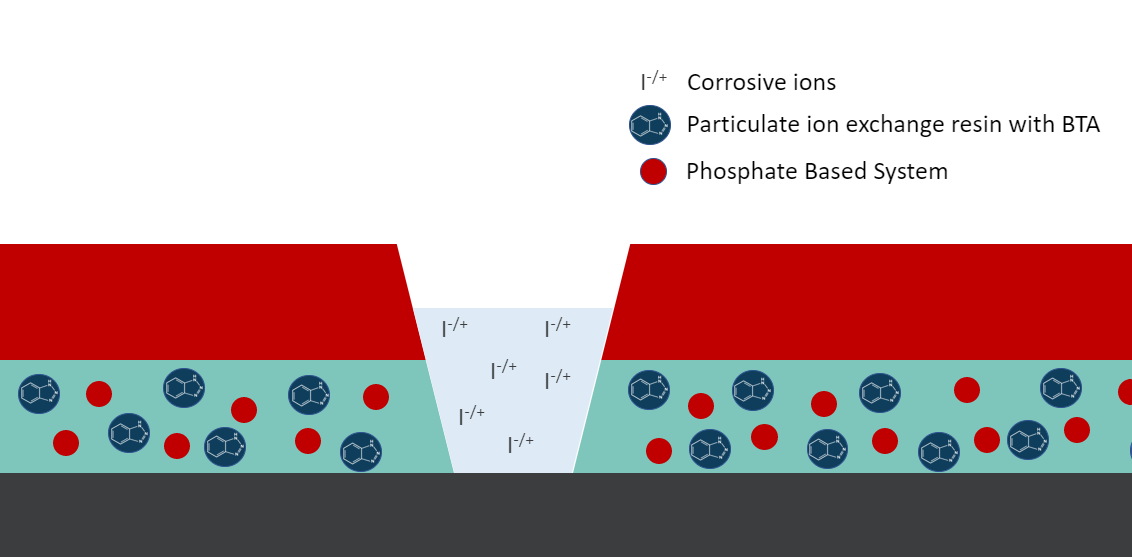

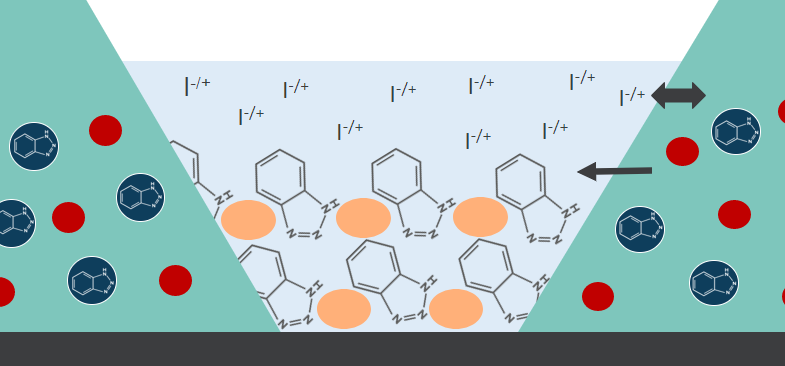

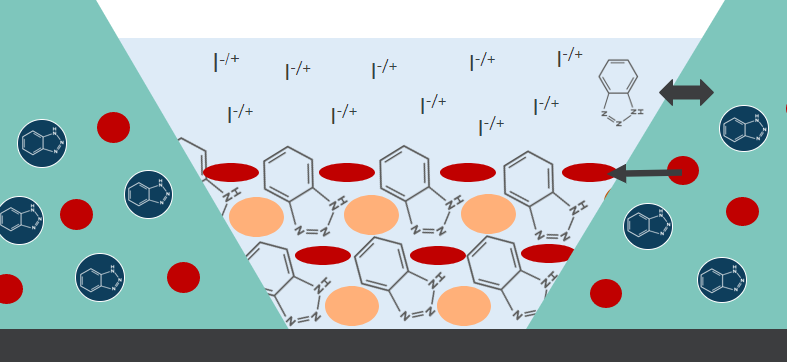

Zinc phosphate salts on their own are not initially very effective due mainly to their low solubility. As a result, in a corrosive environment, significant amounts of time must pass before there are sufficient concentrations of phosphate anions to react with the metal surface cations to form an anti-corrosive precipitative layer. This leads to a time delay where corrosion can proceed unimpeded.4

Intelli-ion® uses ‘smart release’ technology, which senses and reacts to corrosive ions very quickly – buffering the time delay seen with phosphate inhibitors. It sequesters corrosive ions, which triggers the release of the ‘active ingredient’ to form a very fast inhibitive layer at the site of corrosion. Phosphate inhibitors then fill the gaps to form a strong polymeric layer with the metal ions and metal surface. Intelli-ion provides the initial protection backed up by the zinc phosphate precipitate layer to provide an optimized co-blend anti-corrosion solution.

Additionally, like highly effective chromates, Intelli-ion is both an anodic and cathodic inhibitor. This ensures that the technology can reduce the rate of metal dissolution at the anode and simultaneously decreases the rate of reduction reaction (both oxygen reduction and water reduction), via blocking the interfacial transfer of electrons.

Removal of Toxic Warning Labels from Packaging

Sustainability is a key market driver within the coatings industry. In the past, mandatory regulation was the most important factor, but now, we are seeing a fundamental shift in the societal demand with respect to sustainability and responsible business behavior.5 In short, customers are looking for products that are environmentally sound.

Co-blending existing phosphate-based anticorrosion systems with Intelli-ion at loadings less than 2.5% by weight in a paint moves a coating from Environmental Hazard Classification 2 (H411) to Classification Category 3 (H412). Category 3 presents a lower risk to aquatic life so no warning label is required on the paint packaging. In turn, this has storage, transportation, and disposal benefits – not to mention the environmental advantages!

Anticorrosive Cost Savings

Due to the high efficacy and lower loadings – ‘smart’ co-blend formulas with other phosphate containing metal salts can deliver anticorrosive cost savings of 10-30% per liter of paint.

In addition, Intelli-ion also has a significantly lower specific gravity than ZnP, reducing the need for reformulation changes when lower weights of anti-corrosives are incorporated.

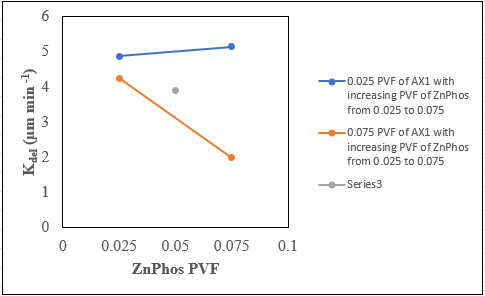

Evidence of Intelli-ion and Phosphate Compatibility

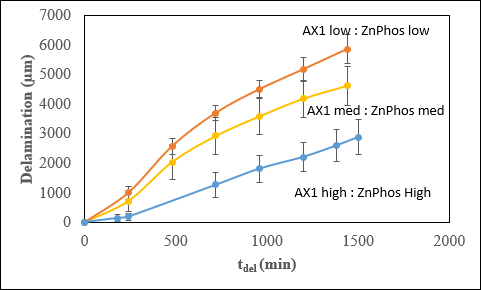

Figures 4 and 5 show research that was conducted by Dr. Phil Ansell of SPECIFIC Innovation & Knowledge Centre, Swansea University. The independent research aimed to understand the relationship and optimal loadings between Intelli-ion and zinc phosphate (ZnP) corrosion inhibitor co-blends. Various volume combinations (PVF – pigment volume fractions) of Intelli-ion and ZnP were applied to a steel substrate, and timelapse photography was used to measure the combined inhibitor effect on the rate of cathodic disbondment (Kdel) over 24 hours.

In Figure 4, the blue line represents the rate of coating delamination when Intelli-ion is held at a low PVF (0.025), and the PVF of zinc phosphate is increased from 0.025 to 0.075. Coating delamination increased with higher concentrations of ZnP. Conversely, the orange line shows that when the PVF Intelli-ion is kept high and constant (0.75 PVF) and the amount of ZnP varies from low (0.025) to high (0.075) – disbondment dramatically decreases. This demonstrates the synergistic effect of the co-blend is optimized when there is a higher loading of Intelli-ion within the coating system. Figure 5 shows the best performing co-blend combination where Intelli-ion and ZnP are both at higher levels.

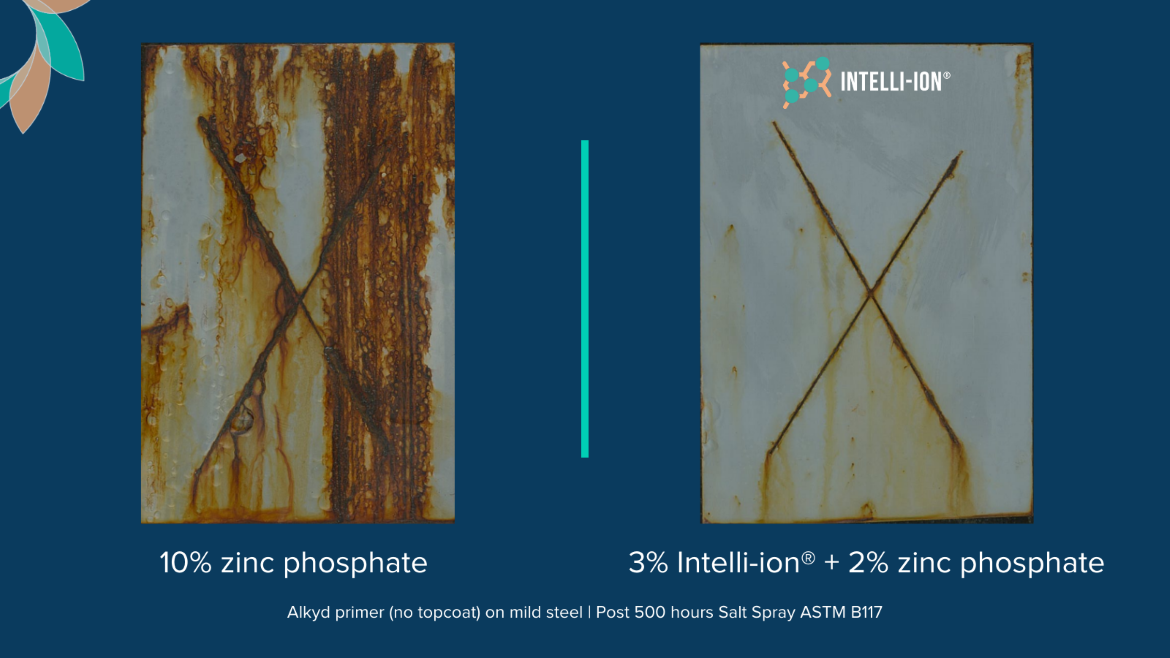

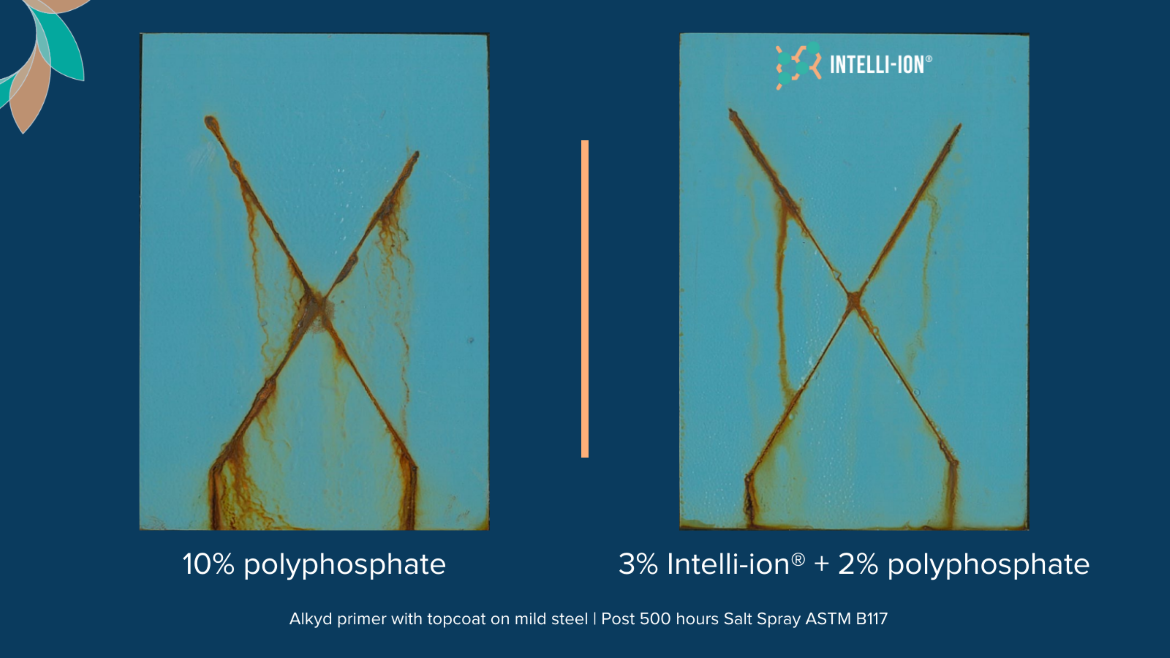

Industry-Standard Salt-Spray Testing

Industry-standard accelerated weathering tests with on-the-market phosphate-based coatings vs. Intelli-ion-containing primers also demonstrate comparable or better performance. Figures 6 and 7 show mild steel samples were coated with an alkyd primer (+/- topcoat) and then scribed using an Elcometer 1638 DIN scratching tool fitted with a 1 mm cutter. The samples were then placed in a salt spray chamber (at 45° angle) and run in accordance with ASTM B117 continuous salt spray fog testing. Following 500 hours, the samples were rinsed using distilled water and dried using lint free cloth before being analyzed.

The inhibitor loading level was optimized for cost and environmental benefits – at a 3:2 ratio – to lower the phosphate content to below 2.5%. This co-blend approach removes the environmental warning labels from packaging, however, the imagery clearly demonstrates that Intelli-ion offers a synergistic relationship in performance with both zinc phosphate and polyphosphates too.

Conclusion

In 2021, the top 15 paints and coatings companies accounted for a total market share of approximately 58.52%.6 In an industry dominated by so few – it’s increasingly important to differentiate your coatings and offer customers quality at a cost they can afford.

Co-blending Intelli-ion anti-corrosives with phosphate-based systems offers a step-change alternative that enhances current coating systems without changes to the manufacturing process. At an optimized 3:2 ratio, coatings manufacturers can remove hazard warning labels from their packaging, reduce their anticorrosion costs – all while benefiting from comparable or better performance.

For more information, visit www.hexigone.com or e-mail info@hexigone.com.

References

1 NACE. (2016, March 1st). Economic Impact. Retrieved from NACE International: http://impact.nace.org/economic-impact.aspx.

2 Hongxia Wan, D. S. (2017, June). Effect of Zinc Phosphate on the Corrosion Behavior of Waterborne Acrylic Coating/Metal Interface. Retrieved from Materials: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5554035/#:~:text=Results%20showed%20that%20adding%20zinc,the%20disbonding%20of%20the%20coating.

3 United Nations. (2021). Globally Harmonized System of Classification and Labelling of Chemicals (GHS). Retrieved from UNECE: https://unece.org/sites/default/files/2021-09/GHS_Rev9E_0.pdf.

4 M.Cohen, M. (2022). The Inhibition of the Corrosion of Iron by Some Anodic Inhibitors. Journal of The Electrochemical Society, Vol 100, Number 5.

5 Cynthia Challener. (2018, April). An Update on Sustainability in the Coatings Industry. Retrieved from Coatings Tech: https://www.paint.org/coatingstech-magazine/articles/an-update-on-sustainability-in-the-coatings-industry/.

6 AKI Research. (2022, April 9th) Global Paints & Coatings Market Competition: Top 15 Players in 2021. Retrieved from AKI Research: https://www.akiresearch.com/post/paints-coatings-market-share-2021.

*Images courtesy of Hexigone.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!