U.S. Navy Mold-Inhibitive Coatings

A Survey and Demonstration

Credit: pigphoto, iStock / Getty Images Plus, via Getty Images.

Operational conditions, including humidity, exposure to atmosphere air, sea spray, and exhaust, can leave Navy surface ships susceptible to fungal growth, which can lead to a health stressor for the ships’ force, and unaesthetic conditions for paint and coatings. Additionally, fungal growth has been shown to feed on the resins, fillers, and plasticizers found in coatings, which could lead to degradation of coating performance over time, and occurrence of corrosion. While current interior coatings such as MIL-PRF-24596 include a mold-resistant performance requirement in accordance with ASTM D3274, no mold-inhibitive coating has been developed for Navy use.1 However, Environmental Security Technology Certification Program (ESTCP) has funded Naval Surface Warfare Center, Carderock Division (NSWCCD), Navy Research Laboratory Stennis Space Center (NRLSSC), and industry partners to develop a mold-inhibiting coating from MIL-PRF-24596 Navy interior coatings. Mold and coating samples were collected from 27 ships across seven geographic locations for DNA analysis and identification. These mold samples were analyzed to determine the most common species and highlight those that are toxigenic. Mold-inhibitive additives were identified and formulated into a qualified MIL-PRF-24596 coating for ship demonstration in 2023.2

Experimental Procedure

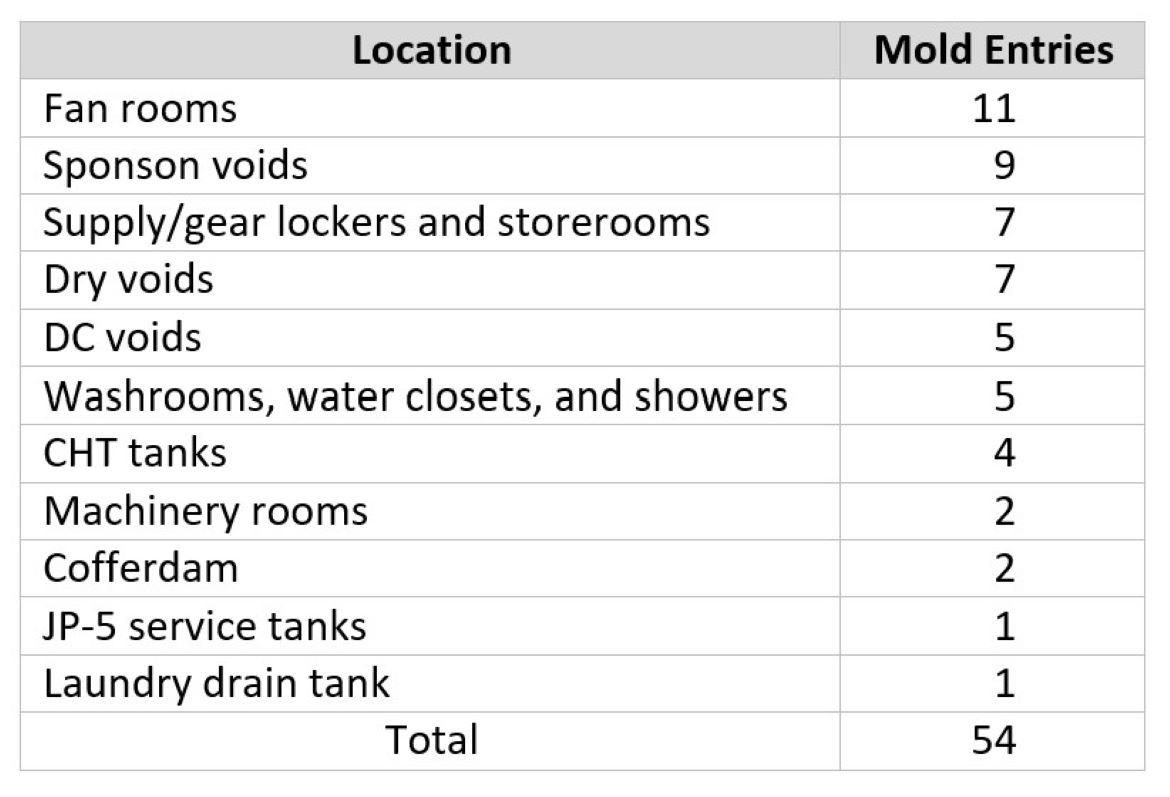

Prior to ship visits, inspection data from maintenance report cards (MRC) was reviewed to identify high-risk compartments for mold growth (Table 1). Review of inspection data collected between 2011 to 2021 described 54 cases in which the certified Shipboard Corrosion Assessment Technician inspecting a given area noted mold or mildew build-up in that area. Mold and mildew are not typically a metric measured in these inspections, suggesting the amount of mold in these areas may have been too excessive to ignore.

TABLE 1 ǀ High-risk compartments for mold growth.

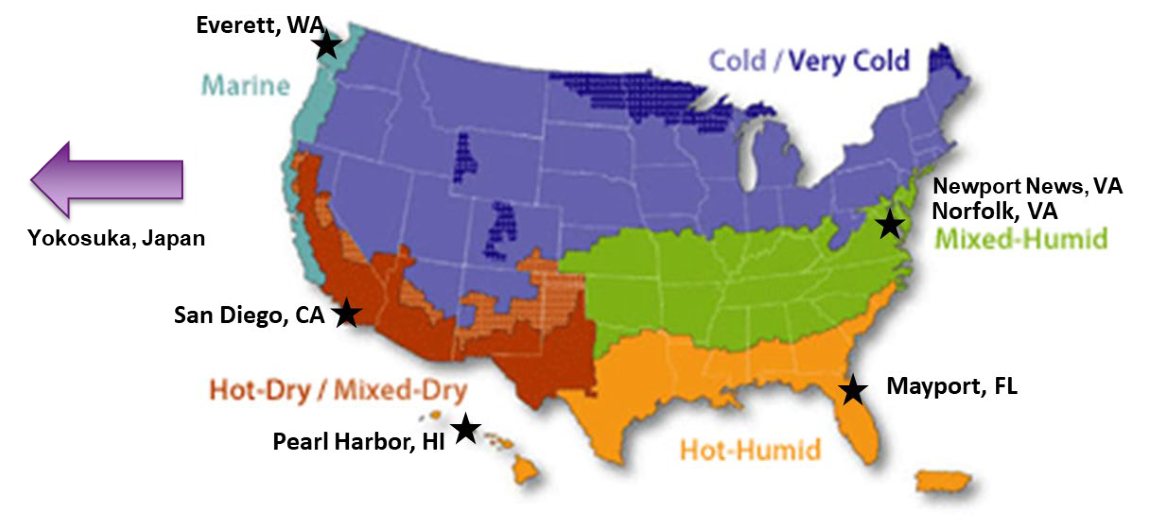

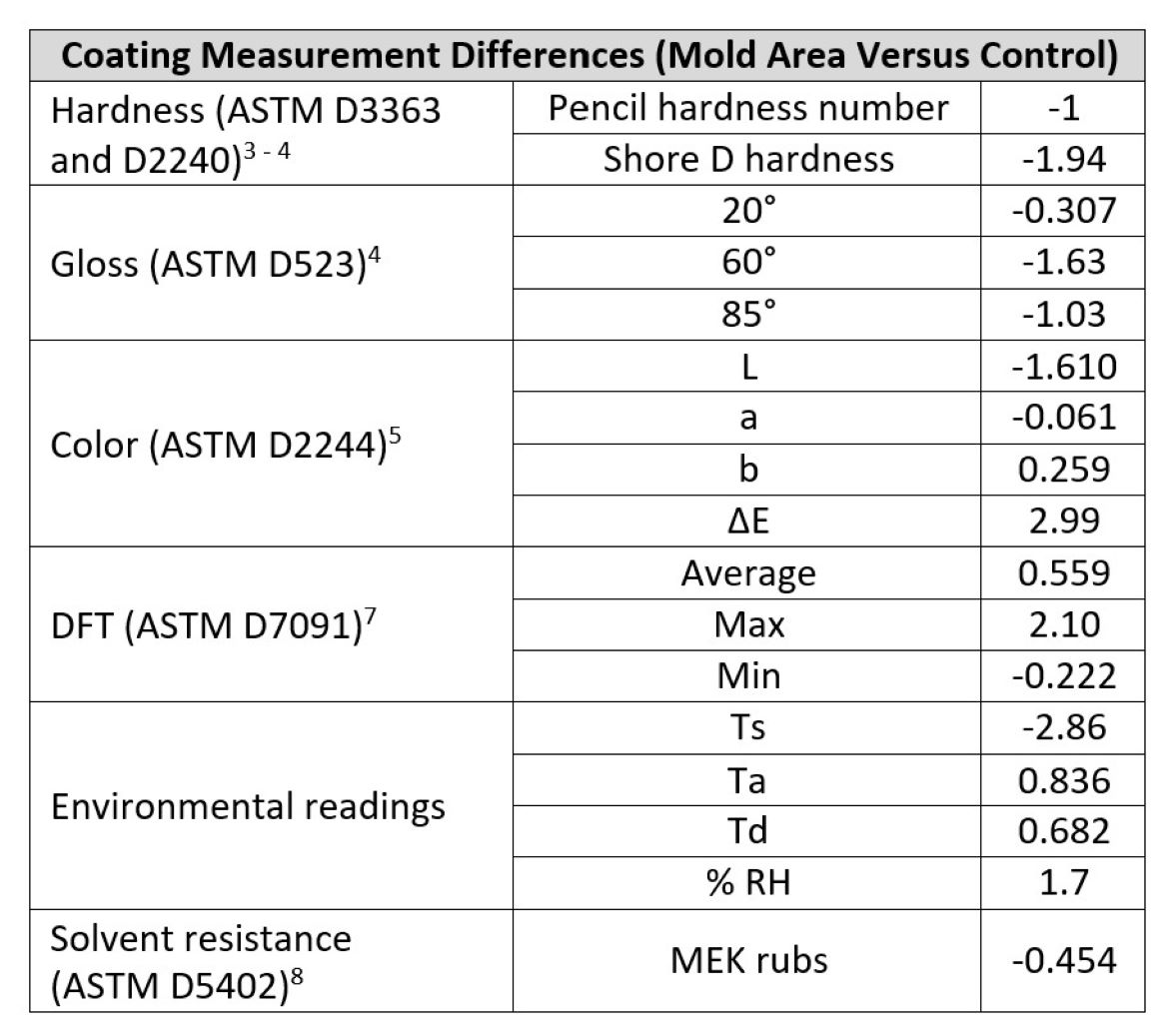

In 2021, ship inspections were performed to determine the extent of the mold issue across the Navy surface fleet. Ships were inspected at seven locations across the continental United States (CONUS) and Japan, each with a unique local climate (Figure 1). The ship inspections consisted of mold swabs, sampling, and physical coating assessments, including measuring coating dry film thickness (DFT), color, gloss, hardness, and solvent resistance. During the inspections, environmental conditions were also measured. These measurements were taken in areas where mold was visually present and compared to control areas where mold was not seen. A summary of the coating assessment is given in Table 2. In general, there was little difference in coating condition in areas affected by mold, with the change in color being the most obvious. It was found that mold grew in locations with lower surface temperatures and higher relative humidity (RH) within a given ship compartment.

FIGURE 1 ǀ Survey locations and temperate zones.

TABLE 2 ǀ Summary of ship inspection data.

Swabs of extant mold growth were collected from the interior surfaces of Navy ships at various inspected compartments. Visible mold was swabbed with a cotton tip and placed in an anaerobic plastic container. Visible mold was sampled three times, and the location and description of each area was recorded. Triplicate swabs for each area were collected and stored in RNALater stabilizing solution for downstream sequencing. Storage in RNALater fixes the fungal sample and stabilizes the genetic material (DNA and RNA) of the sample. In this solution, the sample could be stored at room temperature for up to a week, allowing time for transit to the laboratory for extended storage in a refrigerator.

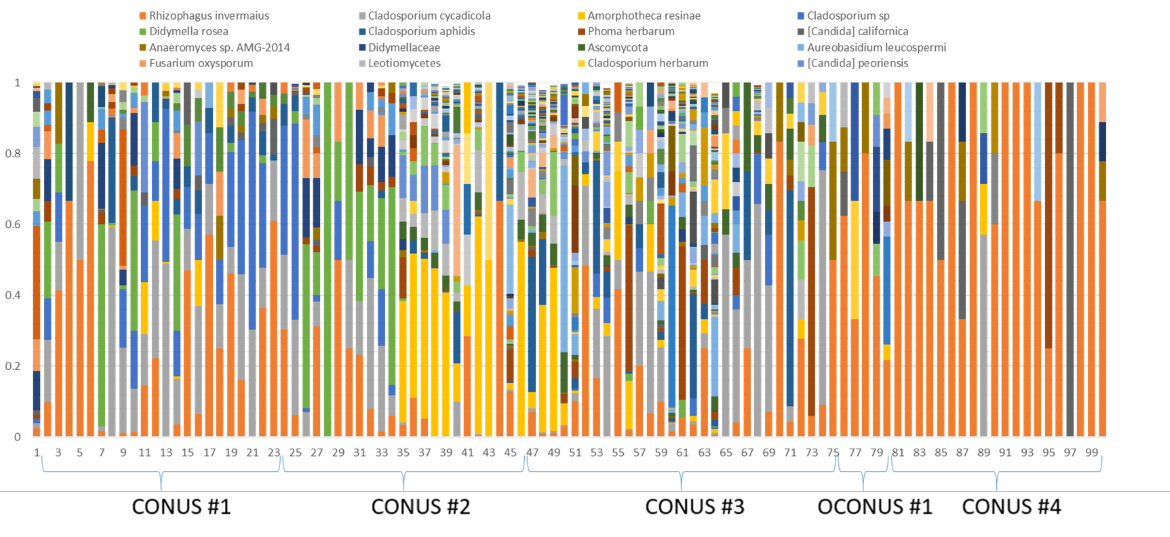

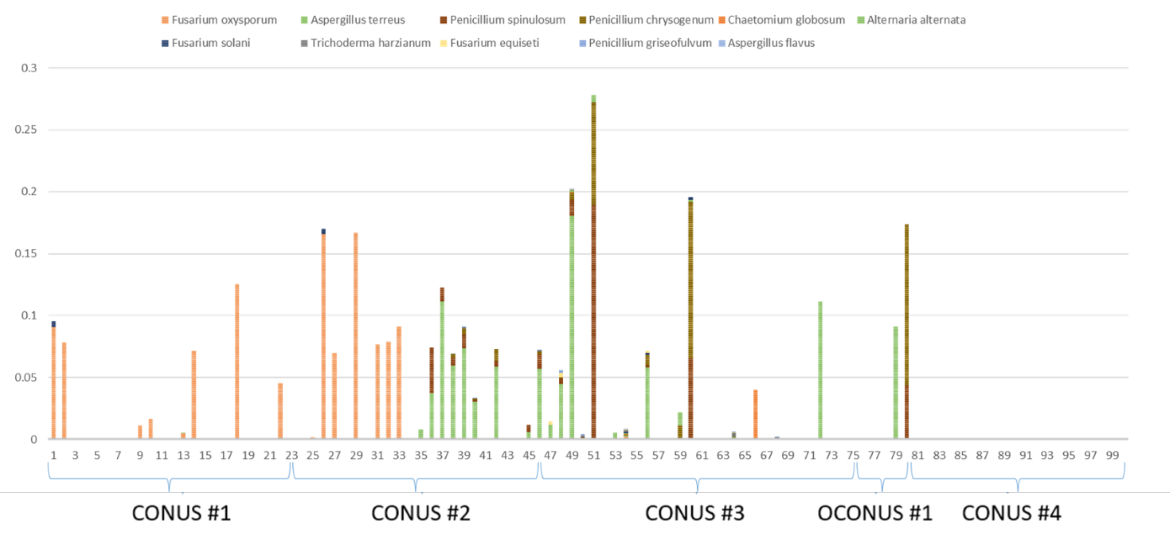

DNA extraction was accomplished using Qiagen DNeasy UltraClean extraction kits following the manufacturer’s protocol. From the ship survey, 123 separate sample locations were processed for their triplicate combined DNA. The concentration and quality of DNA was measured using a NanoDrop spectrophotometer. Samples that had low DNA yield were set aside, leaving 100 samples for downstream processing. These 100 samples of DNA were then sent to Microbial Insights in Knoxville, Tennessee for Next Generation Sequencing. After bioinformatics processing for each sample run, the results were tabulated listing the identified fungal taxa and their associated sequencing hits, i.e., the number of specific gene copies identified for fungal taxa. The raw sequencing hits were converted into relative abundance numbers (normalized to 1.0) for the fungal community of each sample. Figure 2 shows the relative abundance and biodiversity across all samples. The most abundant taxa are included in the legend at the top of the figure.

FIGURE 2 ǀ Relative abundance of fungal taxa across sampled ships.

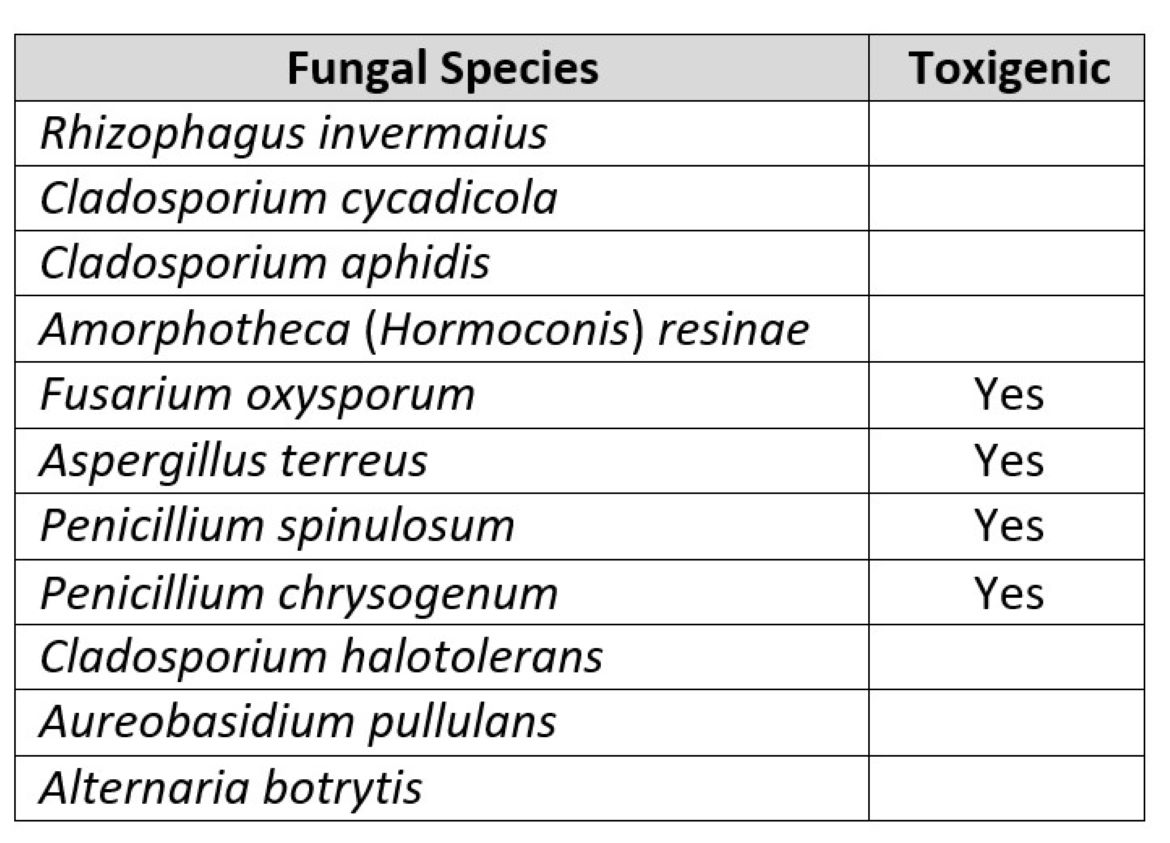

Over 500 species of fungal growth were identified from the 27 ships surveyed. The top 10 most abundant fungal species were identified for each inspection location. Rhizophagus invermaius and Cladosporium cycadicola were within the top 10 most-abundant species at each location. Additionally, the Cladosporium aphidis and Amorphotheca (Hormoconis) resinae were of the top 10 most abundant in three locations. It should also be noted that Fusarium oxysporum was in the top 10 for two of the locations. F. oxysporum is of interest as it is known to be toxigenic (i.e., capable of producing mycotoxins). Mycotoxins are poisonous materials produced by fungi or mold, which can be toxic for humans when absorbed into the skin or inhaled. Even a small amount of mycotoxins can be damaging to human health and even cause death. Figure 3 shows the relative abundance of identified fungal species known to be toxigenic in this study. The four most prevalent toxigenic species were F. oxysporum, Aspergillus terreus, Penicillium spinulosum, and Penicillium chrysogenum.

Samples with the most fungal diversity and richness were selected from each location and sent to an industry partner for independent analysis and verification. The four most abundant fungal species identified were:

- Penicillium chrysogenum

- Cladosporium halotolerans

- Aureobasidium pullulans

- Alternaria botrytis

These are the isolates were independently cultured for testing and analysis by the industry collaborator, analyzed for the most effective inhibitors meeting NAVSEA requirements (e.g., no carcinogenic materials, no heavy metals, and no prohibited materials). The inhibitor packages/blends specifically selected to prevent the growth of the most commonly found molds were mixed into a MIL-PRF-24596 qualified coating. The coating with added inhibitor is currently undergoing testing in accordance with ASTM D5590 and ASTM D3273 to determine the fungal inhibitive properties of the coating (Figure 3).9, 10

FIGURE 3 ǀ Relative abundance of toxigenic fungal species across sampled ships.

Mold-Inhibiting Coating Testing

Mold-Resistance Testing

Several mold-inhibiting additive packages have been developed to prevent the growth of the species determined from analysis of the ship mold samples. These packages are currently being tested in accordance with ASTM D5590, Standard Test Method for Determining the Resistance of Paint Films and Related Coatings to Fungal Defacement by Accelerated Four-Week Agar Plate Assay.9 This accelerated method is for determining the relative resistance of coatings to fungal growth. This test is performed by coating glass fiber filter paper or drawdown strips with the coatings to be tested and inoculating the sample panels with mold samples. Test samples consisted of those coated with standard MIL-PRF-24596 coating and MIL-PRF-24596 coating with added mold inhibitor. In addition to the coated samples, positive and negative growth controls were inoculated as well. Samples were inoculated with the molds listed above as well as the standard test fungi, i.e., Aspergillus niger, Penicillium pinophilum, and Aureobasidium pullanlans, and then incubated at 28 ± 2 °C under ≥ 85% RH for four weeks. After incubation, samples were rated on a scale of 0 to 4 with 0 being no mold growth and 4 being > 60% mold coverage on the sample.

The inhibitor packages were also tested as per ASTM D3273, Standard Test Method for Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber.10 This test is similar to ASTM D5590 but instead tests the resistance of interior coatings to surface fungal growth in a severe interior environment simulated using an environmental chamber.11 In this test, coated metal samples were hung in an environmental chamber held at a relative humidity of > 93% at a temperature of 32.5 ± 1 °C, with the bottom filled with inoculated soil. A negative control material known to support mold growth was placed in the chamber as well. Similar to ASTM D5590, samples were tested for their resistance to the growth of the common molds found on ship, as well as the three standard test fungi. After two to three weeks, the samples were rated for mold contamination from a scale of 0 to 10 with 10 being no mold growth, and 0 being completely covered with mold (i.e., 91-100% surface mold contamination). By two to three weeks, the negative reached a contamination rating between 6 and 4 (30 to 60% coverage).

Additionally, the mold inhibiting MIL-PRF-24596 coating was compared with other interior coatings following MIL-STD-810H.12 A fungal consortium was be generated from select fungal species identified during the genetic analysis. The consortium consisted of the four most abundant species identified by DNA analysis and included the four most abundant toxigenic species identified in the samples. In total, 11 species made the consortium (Table 3).

TABLE 3 ǀ Fungal species to be used in the laboratory exposure.

Fungal species from Table 3 were grown on separate potato dextrose-agar (PDA) plates inoculated from isolates of the identified fungal species as unfixed swabs were also collected during the ship survey. For fungal species that could be isolated, frozen stock specimens were acquired from the American Type Culture Collection (ATCC). PDA was prepared in accordance with manufacturer instructions, and poured into sterile plastic petri dishes to a depth of 1 mm. Fungal species were grown on PDA for two weeks. Condiospores (spores) were harvested by flooding the petri dishes with 10 mL of sterile distilled water and dislodged by softly brushing the colonies with a glass rod. The aqueous spore suspensions were filtered through sterile filters and washed three times by centrifuging for 10 minutes at low speed, discarding the supernatant, suspending the pellets in distilled water, and vortexing to disperse the spores. Appropriate dilutions were then prepared for individual suspensions of 106 spores/mL from each culture. Individual suspensions were mixed before spray application onto coupons.

Coupons were fabricated from aluminum panels (4” x 12”). The panels were painted with the following coatings:

- MIL-PRF-24596

- MIL-PRF-24596 with Mold Inhibitor

- MIL-PRF-24596B Latex Enamel - F25

- MIL-DTL-24607B Chlorinated Alkyd13

- MIL-DTL-24441D Epoxy-Polyamide14

- MIL-PRF-24635F Type V & VI Comp 2 - 2K Polysiloxane15

- MIL-PRF-24635F Type V Comp 1 – 1K Polysiloxane

- MIL-PRF-24635F Type V Comp 1 + Additive – 1K Polysiloxane samples were cut into 2” x 2” coupons for testing.

Three different exposure conditions were used: abiotic, biotic, and control. Abiotic and biotic coupons were to be exposed in an environmental chamber at 30 °C and 95% RH for up to 12 months. Control coupons were to be maintained under laboratory conditions (~ 22 °C and ~ 50% RH) for the same period of time. This method is based on MIL-STD-810H - Method 508.8 Fungus, which details the protocols used to challenge materials to fungal growth. The specific alterations to the standard used in this study are exposure time and selected fungal species. The standard calls for up to 84-days exposure. Prior work performed for Strategic Environmental Research and Development Program (SERDP) regarding the “Mechanistic Study of Fungal Degradation of Organic Coatings used in Aircraft Finish Systems" showed that 84-days exposure was not sufficient to observe coating degradation due to fungi.16 While this effort is not focused on coating degradation, the extended exposure time may provide an insight into changes in fungal biofilm community and align with the shipboard demonstration timeline.

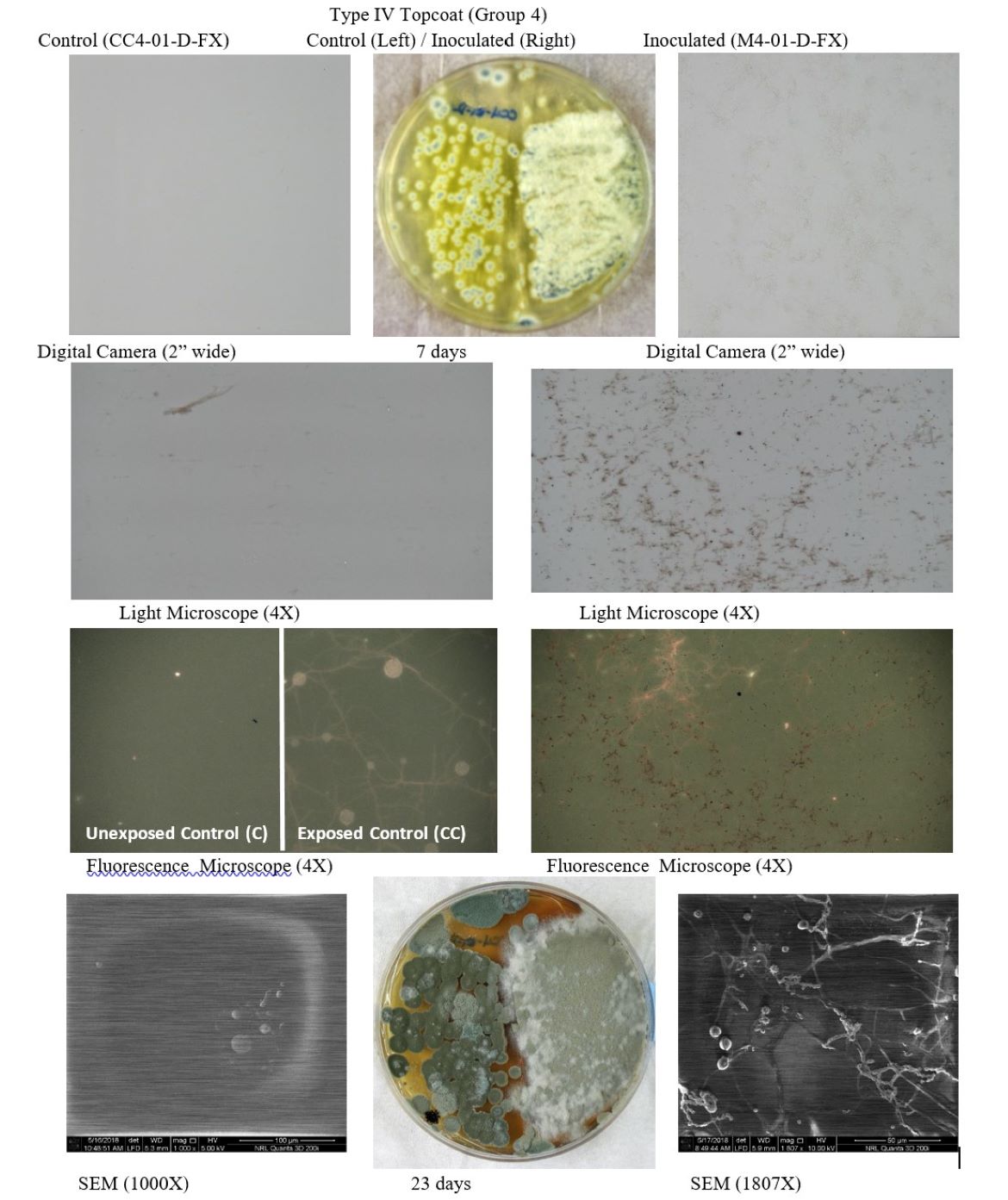

The standard dictates the use of five specific fungal species (Aspergillus flavus, Trichoderma virens, Talaromyces pinophilus, Chaetomium globosum, and Aspegillus brasiliensis) that were selected due to their ability to degrade a wide range of materials. However, none of the five dictated fungal species were within the top 100 in, relative abundance from the shipboard study (Figure 2). Therefore, for the biotic coupons, spore suspensions of the fungi identified from Table 2 were air-sprayed onto the coated coupons. The fungal suspensions were mixed prior to spraying. For the abiotic coupons, the electrolyte used in the fungal suspension (without fungispores) was sterilized and sprayed onto the coupons. All coupons were sterilized under ultraviolet- (UV) light prior to spraying. Abiotic coupons were placed in UV-sterilized containers to prevent contamination for the biotic coupons. Coupons were removed monthly and photographed. At 3-, 6-, and 12-months, coupons will be removed for examination. Fungal growth patterns will be evaluated in terms of area coverage, population identification, and biofilm quantification. Techniques will include molecular methods (e.g., DNA), cell wall constituents, fluorescent staining, spectroscopic techniques, and respiration studies. Microscopic techniques will include environmental scanning electron microscopy (ESEM), and optical and fluorescent microscopies. Figure 4 shows reported examples of fungal contamination on coatings from the prior SERDP report.16

FIGURE 4 ǀ Fungal growth on coated panels with fungal inoculation (right) and without (left).14

MIL-PRF-24596 Conformance Testing

Once the most-effective inhibitor package is determined, the coating will be tested for conformance with MIL-PRF-24596. This testing will occur concurrently with shipboard demonstrations. If conformance is met, the inhibited version of the coating will be added to the MIL-PRF-24596 Qualified Product Database (QPD) and made available to the fleet through standard procurement processes. The conformance testing to be performed is outlined below.

- Color: The color to be tested in this program will be “bright white” as typically used in ship interior spaces. As per MIL-PRF-24596, this color should match the SAE AMS-STD-595 color chip number 27925.17 Per the coating specification, the test used to check the color conformance is ASTM D1729.18 This method is a qualitative determination of color under an illuminated viewing device. In the past, a major paint manufacturer collaborating with this study has submitted color conformance data following ASTM D2244.4

- Mass per Unit Volume (Density): For this test, the mass of liquid paint will be measured in a cup/cylinder at a known volume following ASTM D1475.19 Dividing the weight of the liquid by the volume in the container will give the mass per unit volume (density). The density of the mold-inhibitive coating will be compared to that of the standard coating.

- Viscosity: Coating viscosity will be measured following ASTM D562 Method B.20 This standard uses a digital Stormer viscometer, which spins a set of paddles in the coating and calculates the viscosity based on the resistance offered by the material to the spin. Viscosity measurements will be performed on both the standard coating and the fungistatic version.

- Flash Point: Flash point will be measured using a Pensky-Martens closed cup tester following the procedures in ASTM D3278 Method A.21 In this test, liquid paint samples will be heated in a Pensky-Martens cup over time and exposed to an ignition source. The flash point will be recorded as the temperature at which the coating ignites. The flash point of the mold-inhibitive coating will be compared to that of the standard MIL-PRF-24596 coating.

- Drying and Set-to-Touch Time: Both dry time and set-to-touch time will be measured following ASTM D1640.22 This specification is a qualitative measurement that only requires the tester’s hand and fingers. In the MIL-PRF-24596 specification, “drying time” is equivalent to the “dry-hard” definition in ASTM D1640. The coating will be considered dry-hard when pinching the panel between the thumb and forefinger with a maximum pressure leaves no mark on the surface of the coating. Set-to-touch time is found earlier in the cure process. A coating is considered set-to-touch when no material is transferred when lightly touching the film of the material. Dry and set-to- touch time measurements will be performed on both samples of the standard coating and the mold-inhibitive version.

- Specular Gloss: Specular gloss will be measured following ASTM D523.5 Measurements will be taken using a digital gloss meter. This gloss meter emits a light beam at specific angles of incidence to the surface and measures the reflectance. A combination of the angle and reflectance can be used to determine a degree of gloss. Gloss measurements will be compared between the mold-inhibitive and standard formulations of the coating.

Ship Demonstrations

Socialization of the ship inspections and coating development within the fleet has resulted in two demonstration opportunities in 2023. The first demonstration was performed in January 2023 and the second in April 2023. Both demonstrated the mold-inhibiting benefits of the newly developed MIL-PRF-24596 coating compared to the standard formulation. In addition, the demonstration tests the effectiveness of NavClean at killing and removing existing mold. Figure 5 represents the condition of the demonstration spaces prior to the demonstration.

FIGURE 5 ǀ Representative degree of mold in demonstration spaces.

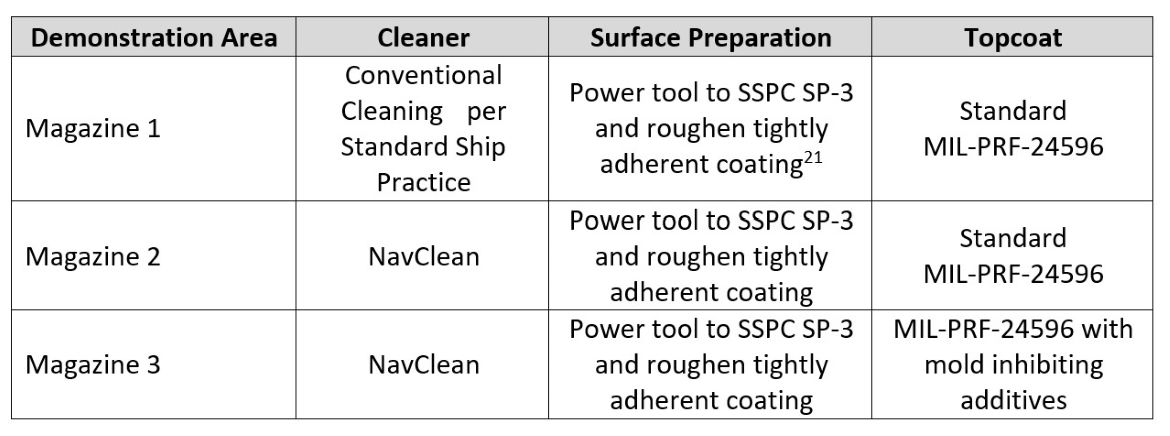

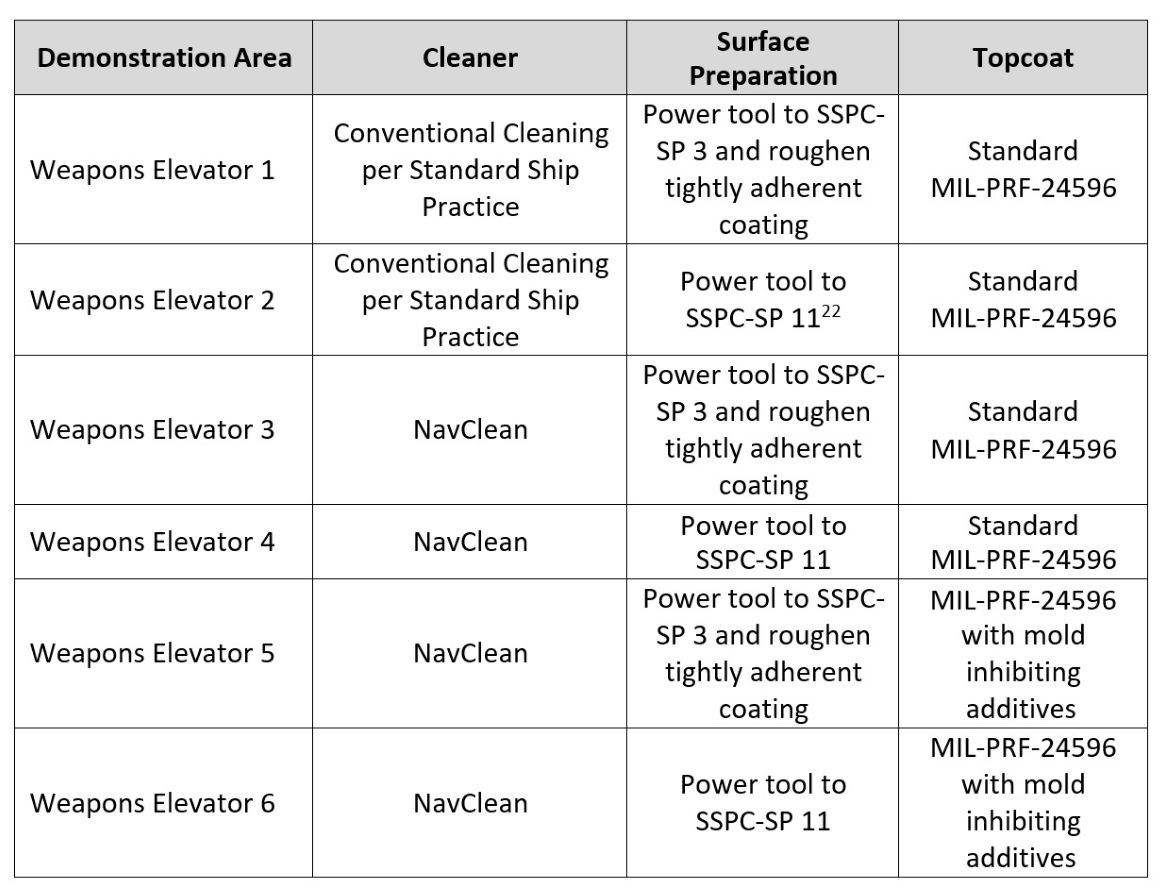

NavClean is a recently developed cleaner created by NAVAIR to combat mold on aircraft. Testing has shown NavClean to be highly effective at killing mold spores and hyphae.16 Alternatively, standard cleaners used in the Navy only remove surface mold while leaving the hyphae to regrow soon after cleaning. The mold-inhibiting MIL-PRF-24596 coating and NavClean are being tested during both ship demonstrations. In one of the ship demonstrations, both products were tested on three magazine spaces. On the other ship, the demonstration took place in six elevator spaces. A summary of the cleaning, surface preparation, and application processes in each demonstration are given in Tables 4 and 5.

TABLE 4 ǀ Ship demonstration one.

TABLE 5 ǀ Ship demonstration two.

Demonstration spaces were evaluated for various metrics at several points during the demonstration process. Prior to work start, each space was swabbed for mold analysis to determine the mold concentration on the surface. Additionally, air sampling was performed to determine the spore concentration in the air. The same locations were swabbed, and the air sampled again after the cleaning step in the demonstration. This data will be used to compare the decrease in mold concentration from cleaning with NavClean in place of standard Navy cleaners.

After surface preparation and coating application, the coating finish was measured for dry-film thickness (ASTM D7091), color (ASTM D2244), and gloss (ASTM D523).5-7 This ensured that the coating with added mold inhibitor met the necessary conformance requirements of MIL-PRF-24596 during the demonstrations. During this time, five, 1’ x 1’ spots, located in areas of the space prone to mold, were marked and documented. Photographic documentation of the spaces were taken with special care to fully photograph the five marked spots.

To complete the demonstrations, follow-up inspections will be performed in the demonstration spaces 6 to 12 months after the completion of the coating application. The exact timeframe for follow-up inspection will depend on ship availabilities. During this inspection, final swabs and air samples will be taken to document the concentration of mold in the spaces. Additionally, the five spots marked after coating application will be documented and measured for mold surface coverage following the scale given in ASTM D3237.10 This data will be used to determine change in mold prevalence resulting from the use of NavClean and the mold inhibitive formulation of MIL-PRF-24596.

Conclusions

Ship inspections performed to document the extent of mold in the Navy fleet found it to be a significant issue. This sentiment has been confirmed by members of the ships’ force who claim to have little options to combat mold. This program has analyzed mold samples taken from ships to determine the most prevalent genera and species living within Navy ships across the world. The results determined that mold is found in high concentrations within spaces of most ships in the fleet. Some of these species were found to be toxigenic, posing a health risk to sailors.

To address the issue, this ESTCP program has begun developing a biocidal mold-inhibiting coating alongside an industry partner for use in ship interior spaces. This coating is based on an already qualified MIL-PRF-24596 coating with the addition of mold-inhibiting additives. Testing is ongoing, but similar technologies have been effectively used in commercial architectural coatings, and early results show promise. Used with the previously developed fungicidal cleaner NavClean, it is expected that this coating will result in a large decrease in growth within mold-prone spaces.

Once the coating formulation is finalized, additional laboratory testing and planned ship demonstrations will be used to determine the extent its benefits. Since the base coating is already qualified to a MIL-SPEC, implementation, assuming successful testing and demonstration, should be timely making the solution available fleet-wide.

References

1 ASTM D3274, Standard Test Method for Evaluating Degree of Surface Disfigurement of

Paint Films by Fungal or Algal Growth, or Soil and Dirt Accumulation (West Conshohocken, PA: ASTM International)

2 MIL-PRF-24596C, Performance Specification - Coating Compounds, Nonflaming, Fire- Resistant, (Washington, DC: Naval Seas Systems Command)

3 ASTM D3363 - 22, Standard Test Method for Film Hardness by Pencil Test (West Conshohocken, PA: ASTM International)

4 ASTM D2240 - 15, Standard Test Method for Rubber Property-Durometer Hardness (West Conshohocken, PA: ASTM International)

5 ASTM D523 - 14, Standard Test Method for Specular Gloss (West Conshohocken, PA:

ASTM International)

6 ASTM D2244 - 21, Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates (West Conshohocken, PA: ASTM International)

7 ASTM D7091, Standard Practice for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metals (West Conshohocken, PA: ASTM International)

8 ASTM D5402 - 19, Standard Practice for Assessing the Solvent Resistance of Organic Coatings Using Solvent Rubs (West Conshohocken, PA: ASTM International)

9 ASTM D5990 - 17, Standard Test Method for Determining the Resistance of Paint Films and Related Coatings to Fungal Defacement by Accelerated Four-Week Agar Plate Assay (West Conshohocken, PA: ASTM International)

10 ASTM D3273 - 21, Standard Test Method for Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber (West Conshohocken, PA: ASTM International)

11 ASTM D5590, Standard Test Method for Determining the Resistance of Paint Films and Related Coatings to Fungal Defacement by Accelerated Four-Week Agar Plate Assay (West Conshohocken, PA: ASTM International)

12 MIL-STD-810H, Department of Defense Test Method Standard - Environmental Engineering Considerations and Laboratory Testing (Washington, DC: Department of Defense)

13 MIL-DTL-24607C, Detail Specification - Enamal, Interior, Nonflaming (Dry), Chlorinated Alkyd Resin, (Washington, DC: Naval Seas Systems Command)

14 MIL-DTL-24441D, Detail Specification - Paint, Epoxy-Polyamide, General Specification For, (Washington, DC: Naval Seas Systems Command)

15 MIL-PRF-24635F, Performance Specification – Coating System, Weather-Resistant, Exterior Use (Washington, DC: Naval Sea Systems Command)

16 Lee, J.; Hanson, D.; Wynne, J.; Brown, S. A.; Daniels, G.; Hansen, D.; Zeszut, R.; Brown, T. SERDP-2747 Final Report: Mechanistic Study of Fungal Degradation of Organic Coatings used in Aircraft Finish Systems, (Patuxent River, Maryland: Naval Air Warfare Center Aircraft Division, 2019).

17 SAE-AMS-STD 595, Colors Used in Government Procurement (Warrendale, PA: SAE AMS)

18 ASTM D1729-22, Standard Practive for Visual Appraisal of Colors and Color Differences of Diffusely-Illuminated Opaque Materials (West Conshohocken, PA: ASTM International)

19 ASTM D1475 - 13, Standard Test Method for Density of Liquid Coatings, Inks, and Related Products (West Conshohocken, PA: ASTM International)

20 ASTM D562 - 10, Standard Test Method for Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using a Stormer-Type Viscometer (West Conshohocken, PA: ASTM International)

21 ASTM D3278 - 2021, Standard Test Method for Flash Point of Liquids by Small Scale Closed-Cup Apparatus (West Conshohocken, PA: ASTM International)

22 ASTM D1640 - 14, Standard Test Methods for Drying, Curing, or Film Formation of Organic Coatings (West Conshohocken, PA: ASTM International)

23 SSPC SP-3, Surface Preparation Standard No. 3 Power Tool Cleaning (Pittsburg, PA: SSPC)

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!