A Close Shave

New PFAS-Free Alternatives to PTFE Surface Lubricating Coatings for Razor Blades Could Mean Great Shaving and a Better

Lubricating coatings on razor blades are thin films that reduce friction between the blade and the skin during shaving and reduce the force required to cut hair. Virtually all shaving razor blades have a PTFE-lubricating coating on the edges to enhance comfort while shaving. While PTFE coatings on razor blades can provide a smoother and more comfortable shaving experience, they have negative environmental impacts because they are not biodegradable and can persist in the environment for a long time. PFAS compounds are a byproduct of the production of PTFE and can also be used in formulations of PTFE powders to keep them in suspension. PFAS are persistent organic pollutants that can accumulate in living organisms and potentially cause a range of health issues, including liver/kidney damage, cancer, and development of disorders.1-3 Due to the potential health effects, there have been restrictions on the use of specific PFAS compounds in the past, and new restrictions are on the horizon.

For example, perfluorooctanoic acid (PFOA) and its salts and related compounds were banned under the POPs Regulation since July 4, 2020.4 New restrictions covering a wide range of PFAS were proposed to ECHA in January of 2023 by the governments of Denmark, Germany, Netherlands, Sweden, and Norway.5 The restrictions advocate for the prohibition of the production, marketing, and use of these substances throughout Europe except in critical applications where there are no acceptable non-fluorinated substitutes (for example, PTFE used in medical devices).

Regulation of PFAS is an ongoing process. The United States Environmental Protection Agency (EPA) set regulatory limits for PFAS, such as in drinking water, and more and more states have implemented their own regulations, including bans on certain uses of PFAS in consumer products.6,7 The EPA also announced plans for regulation that would, for the first time, set limits on the level of PFAS that could be discharged in wastewater. During normal use, over 80% of the PTFE coatings on a razor blade wear down and are washed into the municipal wastewater systems, where no methods exist to remove PFAS from water. Furthermore, in 1990 the EPA estimated two billion disposable razors and blades get tossed out each year in the United States alone.8 Any razors disposed to a landfill could eventually leach remaining PFAS on the blades into the water column over time.

Consequently, there is an urgent need to find PFAS-free coating alternatives to reduce the potential environmental and health risks associated with these substances, and promote the development of more sustainable and responsible products.

PTFE-lubricating coatings date back to1963. They offered the benefit of less force required to cut human hair.9 Coated and uncoated blades were tested under controlled conditions. It was found that there was less tendency for the coated blades to pull, resulting in increased ease of shaving. In the past 40 years, other PTFE-alternative coatings were discovered. Examples include hydrophilic poly (ethylene oxide) and hydrophobic poly (dimethylsiloxane) treatments. However, these PTFE-alternative coatings have not had anywhere near the adoption rate compared to PTFE among the major razor blade manufactures.10, 11 This is likely due to PTFE coatings having the greatest combination of friction reduction and durability on the blade edges. Therefore, current lubricating coatings on razor blades still rely on PFAS-containing materials for all the major manufacturers.

A new class of nanoscale surface treatments, based upon supramolecular self-assembly, are very promising candidates for replacing PTFE on cutting edges, and can provide good cutting performance and durability, while reducing the potential risks to the environment and human health.

Methods and Materials

In view of current proposed legislature in the European Union (EU), Aculon re-evaluated razor blade coatings, given many recent advancements in nanoscale surface chemistry over the last few decades. Several different nanoscale surface treatments were selected over a dozen of Aculon’s advanced nanoscale surface treatments and tested using methodology similar to what is used in the razor blade industry.12 Given that production globally for razor blades runs into the high tens if not hundreds of billions of units annually, any application process designed to replace the current PTFE deposition process must be simple and highly scalable. Treatments were selected that could easily be applied with a simple process.

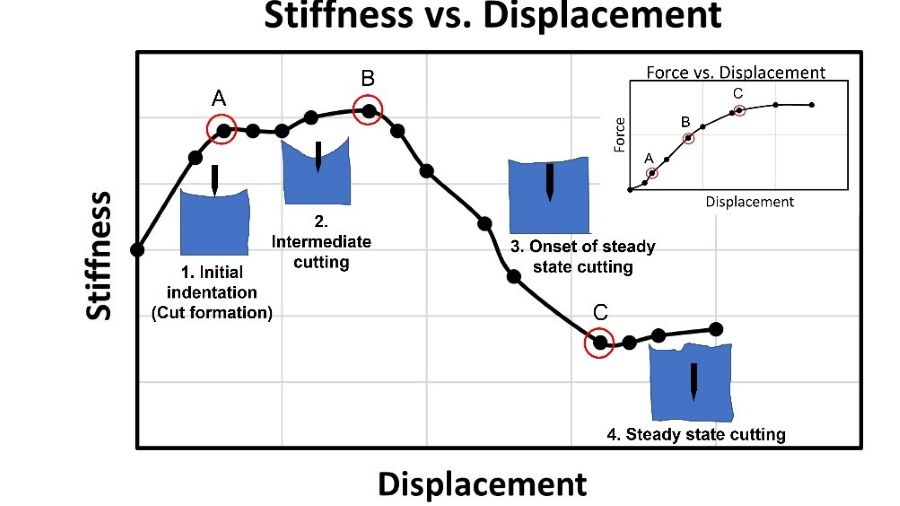

Conventional stainless steel razor blades with symmetric wedge-shaped cutting edges were used during the evaluation to compare many different surface treatments to the conventional PTFE coatings. Tests of the cutting force of treated blades were conducted in a mechanically controlled condition. A razor blade holder was mechanically attached under a force gauge that was placed perpendicularly to the horizontal platform. The razor blade edge was parallel to a horizontal platform. Felt with 3 mm thickness and 2.5 cm width was used as cutting material and placed underneath the razor blade on the platform.13 The razor blade was lowered down until it began to cut the felt perpendicularly. The average cutting force required to penetrate/cut the felt was recorded. It is important to define the cutting force that was used to quantify coating quality. Felt is a soft material, and there are several stages in the cutting process (Figure 1). The trend of change in cutting force and displacement during cutting into the felt is shown in Figure 1. The stiffness (=Force/Displacement) vs. displacement chart illustrates more information about the state of transition.

FIGURE 1 ǀ Indentation cutting with razor blade (stiffness vs. displacement curve).

The felt deforms to some extent when the blade starts to cut. Up to point A, the initial cut forms. Then from point A to B, part of the blade travels inside the felt. From B to C, the whole blade is in the felt. And from point C, steady state cutting happens.

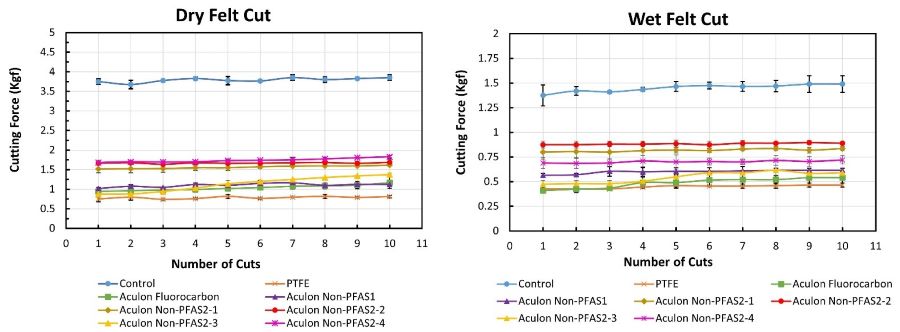

The cutting force that was measured in the test was at point A when the initial cut started to form. Both dry and wet felt were used to measure the cutting force of different treated razor blades. Wet felt was prepared by soaking the dry felt in DI H2O for 20 minutes. Ten cuts were performed in each test to demonstrate durability. Each type of coating was tested three times. Over a dozen different supramolecular coating systems developed by Aculon were tested, including PFAS-containing options and PFAS-free options to compare the effects of fluorocarbon content. The initial tests help downselect potential candidates to a smaller field. Uncoated as control, PTFE coating, Aculon Fluorocarbon, Aculon Non-PFAS1, and Aculon Non-PFAS2-1 to -4. The results of both dry and wet felt cutting tests are shown in Figure 2.

FIGURE 2 ǀ The cutting force of uncoated and different surface-treated razor blades was tested on dry and wet felt.

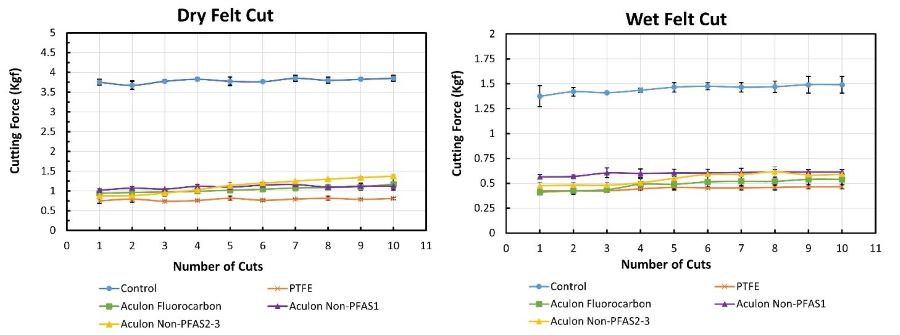

The top three coatings from Aculon, together with uncoated and PTFE-coated results, are presented in Figure 3.

FIGURE 3 ǀ The cutting force of uncoated,PTFE-coated and Aculon’s top three coated razor blades were tested on dry and wet felt.

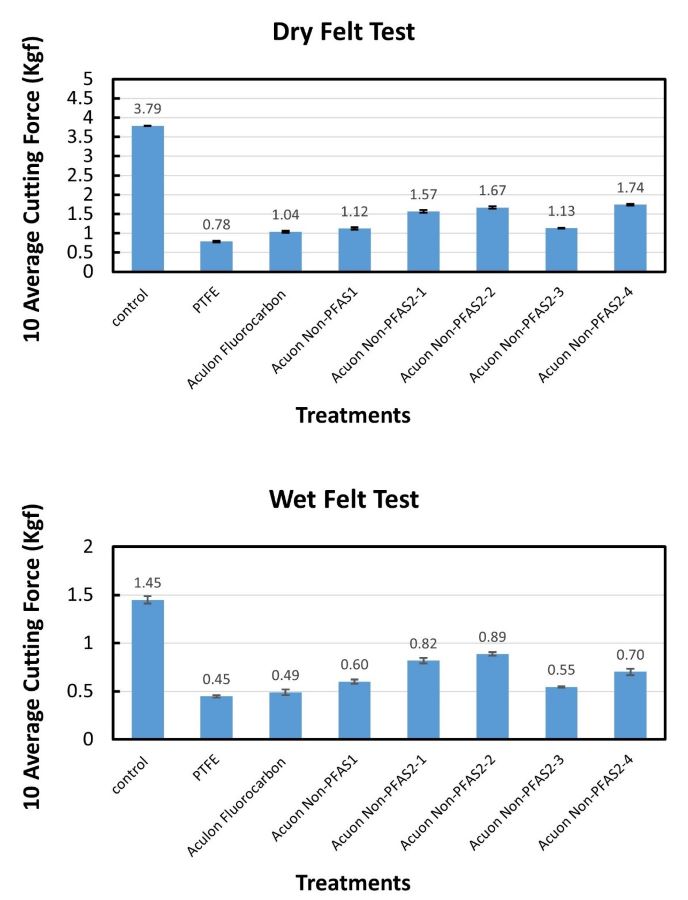

The average force of 10 cuts of each type of treatment is summarized in Figure 4.

FIGURE 4 ǀ 10 average cutting forces of uncoated and different surface-treated razor blades tested on dry and wet felt.

All the treatments show high durability within 10 cuts in both dry and wet felt tests. The PTFE-coated blades display the lowest average cutting force, among all the others. The alternative coatings tested demonstrate significant reductions (more than 50%) in cutting force compared to control (uncoated) and are quite close to the performance of PTFE in both dry and wet felt tests. The slight difference in the felt cutting tests may not be enough to be differentiate in human tactile trails, so it is suggested that future investigations be run with randomized blind shaving trials with human participants.

Conclusion

The Aculon tests indicate that there are potential PFAS-free alternatives available to PTFE for improving lubrication and reducing friction of razor blades. The surface treatments tested in this research displayed performance levels very close to industry-standard PTFE coatings in both dry and wet tests. With further optimization and testing with humans, there will be success in finding PFAS-free alternatives that meet the consumer’s needs and can be produced at very high volume, with a simple process.

References

1 Garg, S.; Kumar, P.; Mishra, V.; Guijt, R.; Singh, P.; Dumee, L.F.; Sharma, R.S. J. Water Process. Eng., 38, 2020, 101683.

2 Anderko, L.; Pennea, E. Exposures to per-and polyfluoroalkyl substances (PFAS): Potential risks to reproductive and children's health. Current Problems in Pediatric and Adolescent Health Care, 50(2), 100760.

3 Langenbach, B.; Wilson, M. Per- and Polyfluoroalkyl Substances (PFAS): Significance and Considerations within the Regulatory Framework of the USA. International Journal of Environmental Research and Public Health, 2021, 18(21), 11142.

4 Bock, A.R.; Laird, B.E. Perfluoroalkyl Substances. Royal Society of Chemistry, 2022, Chapter 1, ebook.

5 ECHA, 2023, ECHA received PFASs restriction proposal from five national authorities, https://echa.europa.eu/de/-/echa-receives-pfass-restriction-proposal-from-five-national-authorities.

6 EPA, 2023, Per- and Polyfluoroalkyl Substances (PFAS) Proposed PFAS National Primary Drinking Water Regulation, https://www.epa.gov/sdwa/and-polyfluoroalkyl-substances-pfas.

7 EPA, 2020, EPA Takes Action to Stop Use of Certain PFAS in Products and Protect American Consumers, https://www.epa.gov/newsreleases/epa-takes-action-stop-use-certain-pfas-products-and-protect-american-consumers.

8 U.S. Environmental Protection Agency, Environmental Consumer’s Handbook, BiblioGov, 1990.

9 Fischbein, I.W. 1963, U.S. patent, 3071856, United States Patent Office.

10 Williams, P.S. 1981, U.S. patent 4291463, United States Patent Office.

11 Spielvogel, D.E.; Zdrahala, R.J. 1989, U.S. patent 4806430, United States Patent Office.

12 McCarthy, C.T.; Hussey, M.; Gilchrist, M.D.; Eng. Fract. Mech., 74 (14), 2007, 2205.

13 Duff, R.R.; Nisby, J.J.; Skrobis, K.J.; Depuydt, J.A. 2018, U.S. patent, 10118304, United States Patent Office.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!