New Materials for Micro-Grinding Beads

- low cost of media;

- high productivity: high wear resistance allows a higher tip speed at lower media densities;

- batch-to-batch consistency in suspension-size distribution;

- limited contamination of the milled formulation;

- low maintenance cost: less frequent stops and fewer parts replaced; and

- low disposal cost.

In general, the wear resistance of beads changes with the density: the higher the density, the higher the wear resistance. Today, we think that in most cases high density is not always suitable for the reasons already indicated.

That is why Saint-Gobain ZirPro has developed a completely new concept of beads based on this dual principle: moderate density, high wear resistance. This new bead is called ZirStarâ. ZirStar is compatible with all mill technologies, and especially the traditional mills, because of its performance and competitive cost. In addition, due to its unique production process, ZirStar allows users to significantly reduce the mill wear. The purpose of this article is to give some practical examples of the value that ZirStar generates.

ZirStar Evaluation

ZirStar is zirconia-based and has been formulated to improve on the already superior wear characteristics of ZirPro's other grinding media. Engineering studies gave birth to a material with finely tuned composition and microstructure that are the keys for a good performing product without reliance on density.First, ZirStar is compared to other ZirPro products (ER120 and Zirmil) in order to have a clear overview of the performance range available. Thereafter, ZirStar is compared to the highest-density ceramic material commonly available in the market (ceria-stabilized zirconia beads).

Two sets of experiments were carried out to evaluate bead wear, milling efficiency and mill wear. The laboratory-scale results are subsequently confirmed in an industrial mill as described below.

Laboratory Testing

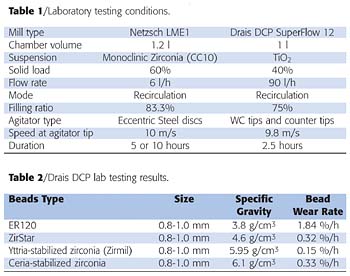

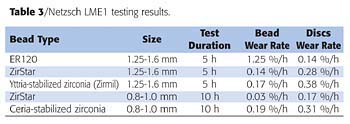

In order to test the product in various milling conditions, we performed milling experiments in different laboratory mill configurations: traditional horizontal mill (Netzsch LME1) and high-energy mill (Drais DCP SuperFlow 12). The test conditions are compared in Table 1. In both cases, the bead wear is evaluated by weighing the bead load before and after the test. In the Netzsch LME1 test, the mill wear is estimated by weighing the agitator discs before and after the test. For each comparable test set the bead size is the same.The results are shown in Table 2 for Drais DCP tests and Table 3 for Netzsch LME1 tests. For comparison purposes, products other than ZirStar and ER120 were also tested in some cases.

The behavior of ZirStar in the high-energy mill Drais DCP is very promising: the wear resistance is only half that of yttria-stabilized zirconia beads, but overall similar to that of ceria-stabilized zirconia and six-times higher than ER120.

We know that, most often, yttria-stabilized zirconia beads are used in high-energy mills. The results tend to support this practice. On the other hand, ZirStar is the result of research focused on the optimization of traditional mill performances. That is why the Netzsch LME1 testing is more relevant.

In Table 3, two series of experiments with different bead sizes and test durations are described. Bead wear rate (and abrasiveness towards mill) clearly depends on the bead size: the finer the beads, the lower the bead and mill wear.

The first test series confirms the relative media performances obtained in Drais DCP mill in terms of bead wear. However, ZirStar is now much closer to yttria-stabilized zirconia beads than in the Drais DCP mill. For the same bead size, the wear of the material is directly linked to the density (ER120: 3.8 g/cm3, ZirStar: 4.6 g/cm3, Zirmil: 5.95 g/cm3 and ceria-stabilized zirconia beads: 6.1 g/cm3): increasing density leads to increasing mill wear.

To confirm the positive results obtained at the laboratory scale, we indicate below the results of the ZirStar testing at the industrial scale.

Industrial Testing

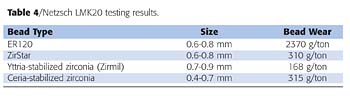

Industrial trials are absolutely necessary to confirm the laboratory results. A horizontal Netzsch mill LMK20 was used to test commercial grade of Zirmil, ZirStar, ER120 and ceria-stabilized zirconia beads (CSZ). The milled suspension is composed of zirconia powder (CS10 grade, median diameter close to 3.5 µm). The mill was filled up to 85% of the chamber volume. At the beginning of each test, the power of the mill was set around 17 kW in order to have nearly the same energy per ton of milled product. Consequently, the rotation speed of the shaft has been adapted to take into account the difference in density between products (ER120: 1150 rpm, ZirStar: 1000 rpm, Zirmil: 950 rpm and CSZ: 930 rpm).Four 500-kg batches of zirconia were milled with Zirmil, ZirStar and CSZ. Two 500-kg batches were milled with ER120. The efficiency is recorded versus mill energy. Bead wear is determined by weighing the load before and after the four (or two) batches. The mill works in a recirculation mode with a flow rate of 500 l/h. The milling was stopped when a median diameter close to 0.8 µm was obtained.

Figures 1 and 2 illustrate the evolution of efficiency in the previously described conditions for the four test media. In Figure 1, the mean diameter (d50) is not bead-type dependant because of the constant mill power input. The slight differences could be attributed to slight bead size variation between the products. The same conclusions can be drawn from Figure 2, which compares ZirStar and CSZ beads.

Bead wear is the most important parameter to extract from these series of tests. Bead weight loss is presented in Table 4. For comparison, bead weight loss is given for one ton of dry milled product.

The relative media performance in terms of bead wear is consistent with the laboratory results. For ZirStar, a higher speed rate compared with ceria-stabilized zirconia beads (1000 and 930 rpm respectively) doesn't markedly effect the bead wear because of its unique fine and tough microstructure.

Conclusion

Saint-Gobain ZirPro has developed a value-based, high-performance media for micro-grinding and micro-dipersion applications. Knowing that the high density of beads is not always suitable, we focused on wear resistance improvement. We carried out numerous tests that show the main benefit of ZirStar is its excellent wear-resistance properties. Also, by developing a unique production process, we are able to strictly control bead quality and reduce cost. Consequently, we consider that ZirStar is the micro-grinding media with the best price/performance ratio in the marketplace.Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!