TiO2 Basics for Paint Appearance and Performance

Courtesy of DuPont Titanium Technologies

Courtesy of DuPont Titanium Technologies

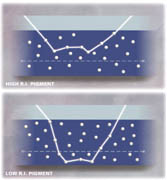

Titanium dioxide is obtained from ilmenite ores using either a sulfate or chloride production process. The sulfate process yields both anatase and rutile crystal forms of TiO2, while the chloride process yields only the rutile crystal structure. Rutile TiO2 is preferred for use in most coatings due to its higher refractive index (R.I.) and hence improved ability to scatter light in paint films. Figure 1 illustrates that light traveling through a film with a higher refractive index pigment will have a shorter overall path length (top illustration) when compared to a film with a lower refractive index pigment (bottom illustration). As long as the film thickness is greater than that indicated by the dotted line in the illustration, both films will appear white and opaque. However, if film thickness is reduced to the dotted line, light traveling through the film with the lower R.I. pigment will be partially absorbed by the substrate causing reduced hiding when compared to the film with the high R.I. pigment, which will remain white and opaque. Thus, choosing a high R.I. pigment such as rutile TiO2 (R.I. =2.73) to maximize the refractive index difference between the pigment and its medium allows for the greatest opacity development in the film. Additionally, TiO2 is unique among pigments in paint formulation because it provides both wet and dry hiding of the substrate by the paint film.

TiO2 particle size and distribution are controlled in the production process and influenced by pigment dispersion in the paint-making process. These properties affect final paint properties such as gloss, dispersion and hiding. Optimal light scattering occurs for well-dispersed TiO2 pigments at a particle size between 0.2-0.3 microns due to the combination of refraction and diffraction of visible wavelengths of light by pigments of this size. As shown in Figure 2, optimal optical properties for a paint film such as hiding power and tinting strength are achieved primarily by optimizing pigment particle size and distribution at less than 0.5 microns. Figure 2 also indicates that as particle size increases, film properties such as gloss and paint properties such as dispersion become negatively affected.

In addition to particle size and distribution, surface treatment is also controlled by the TiO2 production process. Pigment particles are surface treated with alumina, silica and organic coatings to promote dispersibility, hiding, and durability in paints (see Table 1). Grades such as DuPont(tm) Ti-Pure(r) R-902, R-706, and R-960 with moderate silica content are designed to promote photostability in coatings. Therefore, paints made with these grades generally display improved chalk resistance and gloss retention in outdoor applications. Surface coatings are also applied to pigments to act as physical spacers for the pigment particles in paint films leading to superior hide in paints formulated above critical pigment volume concentration (CPVC), as is the case with Ti-Pure R-931.

Courtesy of DuPont Titanium Technologies

Courtesy of DuPont Titanium TechnologiesTitanium Dioxide Grade Selection for Paint Applications

All major TiO2 producers offer a range of titanium dioxide pigments with excellent color and opacity performance. It is important to select the proper grade to achieve additional performance and appearance properties desired in coatings systems. Many key factors must be considered when selecting a grade for coatings applications (see Table 2).

While there is still a range of TiO2 products available, the list can be narrowed down quickly through the use of the checklist found in Table 2 in combination with the grade selection literature provided by titanium dioxide suppliers. When in doubt, consult your suppliers' website or the supplier's sales and technical service organizations.

Courtesy of DuPont Titanium Technologies

Courtesy of DuPont Titanium TechnologiesArchitectural/Decorative Coatings

For architectural or decorative coatings, there are two primary types of TiO2 pigments: those for enamel grade performance below CPVC and those with improved spacing characteristics for above CPVC paint applications. Ti-Pure R-706 and R-931 are available to cover this range of paints. R-931 offers effective hiding and cost efficiency for high-quality flat paints above CPVC if the customer is willing to stock multiple TiO2 products. A range of TiO2 dry and slurry grade choices exist for architectural coatings applications depending upon the need for exterior durability. Recommendations for various applications are listed in Table 3.

Ti-Pure R-706 and R-902 are recommended for use when a single pigment is required to perform well in both interior and exterior gloss and semigloss systems. R-706 is the ideal selection for applications requiring high gloss, maximum gloss retention, and chalk resistance. In addition, the small mean particle size and blue undertone of R-706 will provide brighter, cleaner colors in tinted systems. R-902 is slightly lower in hiding power, gloss, and dispersion than R-900, but higher in exterior durability. For paint manufacturers capable of handling TiO2 in aqueous slurry form, R-706 and R-902 are available in slurry forms-as R-746 and R-942, respectively, (see Table 1).

Ti-Pure R-902 is also highly chalk-resistant; it performs well over a range of solventborne and aqueous systems where tint retention is important. R-900 has medium chalk resistance and is preferred when dirt collection is a problem. These pigments can be used in both alkyd and emulsion paints (see Table 1).

Tinted house paints, including both white and tinted trim paints, require a high degree of chalk resistance and gloss retention. Ti-Pure R-706 is recommended for emulsion trim paints because it provides maximum initial gloss and outstanding exterior durability. These last two properties result from lower PVC and generally better binder durability associated with exterior emulsion trim paints. R-902 also satisfies these requirements over a range of solventborne and aqueous systems.

Ti-Pure R-931/R-941 performs well in selected exterior white latex house paints, following reformulation to accommodate the higher surface area of the pigment and to maintain film integrity. When exterior durability is desired in a flat paint, R-902 is also highly recommended.

Courtesy of DuPont Titanium Technologies

Courtesy of DuPont Titanium TechnologiesOEM and Special-Purpose Coatings

Industrial finishes include a variety of market subsegments such as automotive finishes, powder coatings, coil and can coatings, and maintenance paints. Each has substantially different quality and performance requirements. TiO2 is used primarily to provide hiding or opacity, but grade selection can also have a significant effect on coating gloss, exterior durability, and film cure for acid-catalyzed coatings. The TiO2 grade most appropriate for a particular application depends on the end-use coating properties it affects (see Table 3).In most high-performance coatings requiring exterior durability with excellent color and gloss retention, there are few TiO2s that hit this mark. Most suppliers offer one or two pigment types in this area, such as R-960 for the most demanding exterior durability (gloss and color retention) applications, and R-706, which meets many stringent requirements and can often provide improved initial gloss in combination with the desired gloss and color retention.

For general industrial applications, R-902 multipurpose pigment has been an industry standard for over 35 years. In addition, R-900, R-960, and the modern grades R-700 and R-706 are suitable for many OEM and special-purpose paint applications as well. R-706 and R-960 remain a preferred combination for powder coatings applications. Today, the universal type pigments such as R-706 are being used in a range of general industrial OEM and special-purpose applications where both performance and aesthetics are desired. The universal pigments offer high tint strength, crisp bluer undertones, lower dispersant demand, easy dispersion, high initial gloss, and excellent gloss and color retention. A more detailed discussion of TiO2 grade application by subsegment follows.

Topcoats: Ti-Pure R-706 combines high gloss and distinctness of image with excellent resistance to weathering for high-quality OEM and refinish topcoats. However, R-960 is the most durable Ti-Pure pigment available, making it also ideal for OEM and refinish applications. R-902 is less resistant to weathering than R-960 or R-706 but provides an excellent balance of properties.

Ti-Pure R-706 is the most widely applicable grade, possessing a combination of exceptionally high gloss and excellent exterior durability unique in the industry. It can be used in both interior and exterior coatings where this combination of gloss and durability combined with excellent dispersibility is of value. R-960, although lower in gloss than R-706, provides outstanding chalk resistance and tint retention and should be used in premium-quality exterior finishes where resistance to chalking and color change are of primary importance. Applications include coil coatings for residential aluminum siding and architectural building panels, aerospace coatings, and other high-durability applications. Because of their silica surface treatment, both of these grades provide better film cure in acid-catalyzed coatings than nonsilica-treated grades.

Ti-Pure R-902 is used in high-quality finishes that require very good chalk resistance and gloss retention, but not the exceptional performance provided by R-706 and R-960. This grade is often used in industrial maintenance, implement and transportation finishes, and some container coatings.

Ti-Pure R-700 and R-900 are both used primarily for interior coating applications. R-700 is recommended for most applications and provides the highest gloss combined with a blue undertone for clean tints. Compared with R-900, R-700 provides better film cure in acid-catalyzed coatings because of its neutral pH and lower level of alumina surface treatment. R-900 is widely used for can coatings where its neutral undertone and high gloss are valued. Applications for both grades include appliance coatings, metal furniture finishes, and high-reflectance white coil coatings.

Courtesy of DuPont Titanium Technologies

Courtesy of DuPont Titanium TechnologiesInventory Simplification

Architectural Coatings. The difference in TiO2 performance between alkyd and emulsion flat paints is usually negligible. Occasionally it is desirable to use one pigment over a range of PVCs in interior and exterior flat and semigloss paints. For these applications, we offer a choice of two gloss grades, R-706 and R-902, or their respective slurry counterparts, R-746 and R-942. R-902 or R-706 can successfully replace R-931 in a range of flat paint formulations following adjustments in the formula to accommodate differences among pigments. R-706 is a universal pigment and its selection will provide improved gloss performance as well as maximum gloss retention and chalk resistance in a wide range of solvent and waterborne systems.

OEM and Special-Purpose Coatings. While it is possible to use a single universal pigment such as R-706 over a range of industrial applications, typically most coatings producers still use at least two or three pigments. One TiO2 grade typically is a multipurpose grade such as R-902, another would be a universal pigment such as R-706 for high gloss, and third an R-960 type for the most demanding exterior gloss and color retention applications. Because most industrial producers participate in a range of market end-uses, a single TiO2 grade is a more challenging goal as compared to decorative coatings applications.

Courtesy of DuPont Titanium Technologies

Courtesy of DuPont Titanium TechnologiesMaximizing TiO2 Efficiency in Paints

While the inherent TiO2 pigment properties and the choice of grade influence paint performance, achieving proper dispersion also plays a key role in maximizing TiO2 benefits in coatings applications. To achieve increased efficiency for TiO2 in a paint formulation, several practical aspects of dispersion must be considered.First, consider the initial wet-in of the pigment in an appropriate solvent system. Wetting of the pigment occurs when air or other substances are displaced from the pigment surface by solvents and/or wetting agents such as surfactants or dispersants. The wetting rate is influenced by the surface treatment on the pigment and by wetting agents included in the formulation. Following wet-in, shear must be applied in a grinding step to break up pigment aggregates and agglomerates. The level of shear stress must be determined for each pigment grade to yield a reasonable evaluation of the ease of dispersion for that grade in a defined system. The shear stress applied to the system differs markedly depending on the type of equipment involved and must be evaluated independently for high-speed dispersers, sand grinders, roller mills, and pebble mills. The success of the dispersion and grinding process is reflected in the gloss and tint strength of the final paint and in the dispersion measurements made on the paint grind. As a final consideration, well-dispersed TiO2 particles must be stabilized within the paint system by either charge or steric stabilization.

Flocculation, or loose clumping of TiO2 particles, may occur as the result of poor dispersion or mismatched surface interactions of the pigment with other components in the paint formulation brought on by temperature, pH, or improper type or concentration of dispersant. Flocculation should be avoided as it may lead to issues with viscosity, color acceptance, grind consistency, gloss and hiding in the paint film.

Summary

Achieving maximal value for TiO2 in a coating is a combination of the inherent properties of the pigment, the appropriate choice of grade for the target application, and adequate dispersion in the coatings system. Properties such as pigment particle size and surface coating influence key paint behavior parameters such as gloss, durability, and opacity. Choosing the proper grade allows the user to maximize efficiency specific to the desired application. Proper dispersion of the TiO2 in the paint system will influence the time required to make the paint as well as properties such as color acceptance, tint strength, hiding and gloss. Therefore, all three considerations - inherent TiO2 characteristics, choice of grade, and proper dispersion - must be optimized to achieve maximal benefit from incorporation of TiO2 into a paint.Ti-Pure(r) is a registered trademark of DuPont for its brand of titanium dioxide.

For more information on titanium dioxide, contact Stephen J. Hurff, Ti-Pure Product Manager, Coatings, DuPont Titanium Technologies, Chestnut Run Plaza, Building 709, Wilmington, DE 19880-0709; e-mail Stephen.J.Hurff@usa.dupont.com; phone 302/999.4140; fax 302/999.2479; or Circle Number 121.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!