Specifying Green Paint Products? Consider VOC Emissions, Not Just VOC Content

An important consideration when selecting green

products is what criteria

to use to evaluate which paints do the best job of minimizing VOCs in indoor

air.

As a decorating choice, coatings remain as

popular as ever, with specifiers and consumers also showing strong interest in

using green products. An important consideration when selecting green products

– and a point of some confusion in the marketplace – is what criteria to use to

evaluate which paints do the best job of minimizing VOCs in indoor air.

As a decorating choice, coatings remain as

popular as ever, with specifiers and consumers also showing strong interest in

using green products. An important consideration when selecting green products

– and a point of some confusion in the marketplace – is what criteria to use to

evaluate which paints do the best job of minimizing VOCs in indoor air.

Historically, the focus has been on the contribution of VOCs to outdoor air pollution, in particular ozone and smog formation. To reduce the impact of VOCs in coatings on the outdoor environment, federal and state regulations set limits in terms of VOC content, usually expressed as grams per liter minus water. As a result, coating manufacturers have complied with these regulations by reducing the VOC content in their products.

However, relying strictly on content verification can be misleading, since it does not give a clear picture of how much of a particular VOC or the total amount of VOCs from paint may be getting into indoor air. Nor does it give an accurate picture of how the VOC emissions from a product will affect the total VOCs in the area where paint is being applied. For example, results of air sampling studies have shown when paint is drying, indoor VOC levels can be 1,000 times higher than in outdoor air. Some VOCs can cross contaminate other indoor materials and then continue to outgas for an extended time.

Limiting exposure to VOC emissions is important in protecting public health. VOC exposure has been linked to respiratory illnesses, such as allergies and asthma, memory impairment, headaches, reproductive and developmental problems, sensory irritation, immunosuppression and cancer. Keep in mind that health impact may be dependent on specific VOCs, levels of VOCs, and potential mixtures of VOCs.

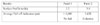

Another point of confusion is coating products marketed as having low or no VOCs can still emit significant amounts of VOCs into the indoor air. The results of a comparative study of VOC content/emissions, conducted by Air Quality Sciences (AQS), illustrates this important point (see table below) and underscores that the only accurate way to ensure a healthy indoor environment is to measure VOC emissions from the products themselves.

In recognition of the health risks associated with VOC emissions, the Collaborative for High Performance Schools (CHPS) green construction program defines acceptable indoor air quality (IAQ) performance based on a product's emissions levels. In addition, U.S. Green Building Council's LEED® for Schools has strengthened its criteria to encourage the use of low-emitting products, including coatings.

To meet regulatory and market demands and to reduce product liability risks, coatings manufacturers will increasingly need to demonstrate their technology leadership by testing and monitoring VOC emissions to ensure their products emit low levels of VOCs and potentially reformulate those products that do not comply with emission limits.

The most reliable and scientifically proven way to test for VOC emissions is by using environmental chamber technology (ECT). This method allows a product to produce emissions similar to the way the product would perform in a home, office or school. The collected data is then mathematically modeled to determine exposure concentrations produced by product application in many different indoor environments.

Those who embrace a strategy of VOC emissions testing, along with responsibly using products that are certified as low emitting (not just low VOC content), will realize major benefits, including:

Visit www.uptilt.com/c.html?s=3jj,15pqf,2oqy,kdgo,khkd,9962,4xmy to learn more about how environmental chamber testing can help you, or call 770/933.0638 and ask for Product Evaluations to order the analysis. Also, visit Aerias, the AQS IAQ Resource Center, to learn more about VOCs and other indoor pollutants. Aerias may be accessed from the AQS website or at www.uptilt.com/c.html?s=3jj,15pqf,2oqy,d1fo,es1g,9962,4xmy. For a listing of products that are certified to emit low levels of VOCs, visit the GREENGUARD Environmental Institute site at www.uptilt.com/c.html?s=3jj,15pqf,2oqy,fdd5,27a3,9962,4xmy.

This article provided courtesy of Air Quality Sciences, Inc.

Historically, the focus has been on the contribution of VOCs to outdoor air pollution, in particular ozone and smog formation. To reduce the impact of VOCs in coatings on the outdoor environment, federal and state regulations set limits in terms of VOC content, usually expressed as grams per liter minus water. As a result, coating manufacturers have complied with these regulations by reducing the VOC content in their products.

However, relying strictly on content verification can be misleading, since it does not give a clear picture of how much of a particular VOC or the total amount of VOCs from paint may be getting into indoor air. Nor does it give an accurate picture of how the VOC emissions from a product will affect the total VOCs in the area where paint is being applied. For example, results of air sampling studies have shown when paint is drying, indoor VOC levels can be 1,000 times higher than in outdoor air. Some VOCs can cross contaminate other indoor materials and then continue to outgas for an extended time.

Limiting exposure to VOC emissions is important in protecting public health. VOC exposure has been linked to respiratory illnesses, such as allergies and asthma, memory impairment, headaches, reproductive and developmental problems, sensory irritation, immunosuppression and cancer. Keep in mind that health impact may be dependent on specific VOCs, levels of VOCs, and potential mixtures of VOCs.

Another point of confusion is coating products marketed as having low or no VOCs can still emit significant amounts of VOCs into the indoor air. The results of a comparative study of VOC content/emissions, conducted by Air Quality Sciences (AQS), illustrates this important point (see table below) and underscores that the only accurate way to ensure a healthy indoor environment is to measure VOC emissions from the products themselves.

In recognition of the health risks associated with VOC emissions, the Collaborative for High Performance Schools (CHPS) green construction program defines acceptable indoor air quality (IAQ) performance based on a product's emissions levels. In addition, U.S. Green Building Council's LEED® for Schools has strengthened its criteria to encourage the use of low-emitting products, including coatings.

To meet regulatory and market demands and to reduce product liability risks, coatings manufacturers will increasingly need to demonstrate their technology leadership by testing and monitoring VOC emissions to ensure their products emit low levels of VOCs and potentially reformulate those products that do not comply with emission limits.

The most reliable and scientifically proven way to test for VOC emissions is by using environmental chamber technology (ECT). This method allows a product to produce emissions similar to the way the product would perform in a home, office or school. The collected data is then mathematically modeled to determine exposure concentrations produced by product application in many different indoor environments.

Those who embrace a strategy of VOC emissions testing, along with responsibly using products that are certified as low emitting (not just low VOC content), will realize major benefits, including:

- achieving green building credits;

- increasing goodwill and positive PR associated with industry leadership in addressing public health issues;

- reducing the risk of product liability lawsuits; and

- receiving fewer product-related odor and irritation complaints from building occupants.

Visit www.uptilt.com/c.html?s=3jj,15pqf,2oqy,kdgo,khkd,9962,4xmy to learn more about how environmental chamber testing can help you, or call 770/933.0638 and ask for Product Evaluations to order the analysis. Also, visit Aerias, the AQS IAQ Resource Center, to learn more about VOCs and other indoor pollutants. Aerias may be accessed from the AQS website or at www.uptilt.com/c.html?s=3jj,15pqf,2oqy,d1fo,es1g,9962,4xmy. For a listing of products that are certified to emit low levels of VOCs, visit the GREENGUARD Environmental Institute site at www.uptilt.com/c.html?s=3jj,15pqf,2oqy,fdd5,27a3,9962,4xmy.

This article provided courtesy of Air Quality Sciences, Inc.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!