Environmentally Compliant, Deflocculating Wetting and Dispersing Agent for Aqueous Dispersions

Pluracoat® CF 20 was developed as an effective and environmentally compliant deflocculating dispersing and wetting additive.

Due to the changing environmental climate as well as market initiatives, paint and coating formulators are being driven to develop more eco-sustainable products. This includes the reduction and/or elimination of volatile organic compounds (VOCs) as well as alkyl phenol ethoxylates (APEOs) from coating formulations. APEO compounds have become less acceptable, due to the harmful effects of their degradation products on aquatic life forms and their potential effect on organism fertility. The latter considerations are mainly responsible for paint manufacturers and raw materials suppliers choosing to work with environmentally friendly materials, gradually phasing out, or banning outright, the use of APEO compounds, despite the absence of any legislative guidelines prohibiting their use.

Credit: BASF Corporation Credit: BASF Corporation

|

| Table 1 Click to enlarge |

Alkyl phenol ethoxylates have found their way into a variety of industrial formulations due to their excellent wetting/dispersing properties, wide range of operability and favorable cost/performance, despite their higher water sensitivity and foam stabilization. In an attempt to overcome these limitations, modern dispersing agents are based on high-molecular-weight acrylate or urethane polymers that offer enhanced steric stabilization and improved water sensitivity. However, sheer size of these molecules renders them ineffective wetting agents.

The wealth of industrial experience dictates that efficient and homogeneous distribution of solid pigments is a key factor affecting the performance, stability and ultimate profitability of the paint formulation. In order to fully develop properties of pigmented dispersions and eliminate defects (i.e., flocculation, color shift, flooding, floating, leveling, settling), pigment agglomerates and aggregates are broken down to their fundamental particles and distributed homogeneously throughout the medium. This process usually consists of three fundamental steps:(1,2)

- wetting agglomerates by the medium;

- separation of the pigment particles; and

- stabilization of the pigment particles in the dispersed state preventing reagglomeration and flocculation.

Although fundamentally distinct, these stages are interrelated and largely overlap. Thus, wetting additives enable the wetting of pigment agglomerates and dispersing additives improve stabilization of the pigment dispersion. In reality, the same product can function as both. Such products adsorb onto the pigment surface and maintain proper pigment spacing through electrostatic repulsion or steric hindrance. This reduces the tendency towards uncontrolled flocculation and agglomeration driven by the high surface energy and omnipresent van der Waals forces.

Dispersing agents could simply be classified according to their chemical structure(3) as anionic, cationic and nonionic. However, it is far more important to distinguish them based on whether the additives stabilize the deflocculated or flocculated state.(4) In flocculated stabilization, the controlled flocculating wetting and dispersing additives form three-dimensional structures responsible for thixotropic behavior and improved sagging and settling, flooding and floating. On the other hand, deflocculating dispersing and wetting additives provide dispersions of small particles with Newtonian flow and lower viscosity, allowing high pigment loading. All these will result in high gloss, increased color strength and more efficient pigment utilization. Such additives are typically low-molecular-weight polymers that adsorb upon the pigment surface and stabilize deflocculated condition by steric hindrance.

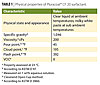

The main focus of this work was to develop a zero-VOC and APEO-free highly effective deflocculating wetting and dispersing agent with low foam and water sensitivity profile. Pluracoat® CF 20 is a nonionic deflocculation dispersing and wetting additive for water-based coating systems. It has been designed specifically to provide superior performance in wetting, dispersing and deflocculation of pigment particles and to comply with environmental regulations (Table 1).

Viscosity of Paint Dispersions

Credit: BASF Corporation Credit: BASF Corporation |

| Figure 1 Click to enlarge |

Rheological evaluation is possibly the most common technique for assessment of pigment dispersant effectiveness in coating formulations. Tremendous reduction in viscosity is one indicator of dispersive power providing an analytical tool for comparative studies of various surfactants. For the purpose of this study, Pluracoat® Performa CF20 was compared against an industry-standard APEO-based (Octylphenol Ethoxylate, capped) color float/color acceptance additive (Sample A). This dispersant/wetting agent has been widely used in architectural and industrial coatings for improved color acceptance as well as imparting freeze/thaw stability. Despite the environmental pressure, Sample A remains an excellent benchmark due to its outstanding performance. Both additives were added to the paint dispersions at the same loading level of 3.5 lb/100 gal.

Credit: BASF Corporation Credit: BASF Corporation |

| Table 2 Click to enlarge |

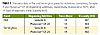

Figure 1 and Table 2 present viscosity data obtained for flat and semi-gloss paint dispersions. Age stability test results (Figure 1) indicate that both surfactant additives are powerful and efficient dispersing agents that significantly reduce the viscosity and provide dispersion stability over the time range tested in this study. Table 2 data also indicate that both dispersing agents provide excellent heat stability, since the paint viscosities remain mainly unchanged after 14 days of exposure to 50 °C. Both dispersing additives provided comparable stabilization effect on the paint formulations. No significant differences were observed between the Sample A and Pluracoat® CF 20 formulations.

Freeze/Thaw Stability

Credit: BASF Corporation Credit: BASF Corporation |

| Figure 2 Click to enlarge |

Freeze/thaw stability test results, depicted in Figure 2 for the semi-gloss formulation, suggest very good compatibility of Pluracoat® CF 20 with the paint formulation and its comparable performance with Sample A. In fact, the overall rise in viscosity after five freeze/thaw cycles was only 5.0 and 5.5 KU for Sample A and Pluracoat® CF 20 containing dispersions, respectively. Note that the same paint, free of dispersing additive, failed this test. This fact suggests that Pluracoat® CF 20 is indeed a very effective deflocculating dispersing additive.

Adhesion

Credit: BASF Corporation Credit: BASF Corporation |

| Table 3 Click to enlarge |

Adhesion results obtained for the flat and semi-gloss dispersion systems tested in this study are listed in Table 3. Based on the results, it is evident that the choice of the dispersing agent did not have a significant effect on the adhesion properties. Both dispersing agents revealed excellent adhesion.

Water Resistance

Credit: BASF Corporation Credit: BASF Corporation |

| Table 4 Click to enlarge |

Water resistance of the resultant coatings is one of the primary formulating concerns when selecting surfactants and additives for performance optimization. Water resistance data for the flat and semi-gloss formulations tested in this study are presented in Table 4. As evident by the data, Pluracoat® CF 20 not only matched the performance of the Sample A additive, but it also decreased the water uptake of the coating by 15% in flat and 6% in semi-gloss formulations. These very encouraging results should provide additional flexibility to the paint formulators when balancing performance and stability attributes of the complex coating systems.

Pigment Dispersion and Color Evaluation

Credit: BASF Corporation Credit: BASF Corporation |

| Table 5 Click to enlarge |

In addition to dispersion stability tested by rheology and freeze/thaw stability, efficiency of pigment utilization is best revealed by color development testing. The performance of Pluracoat® CF 20 was evaluated relative to that of Sample A dispersing additive. Tables 5 and 6 present color development data for Universal Red organic colorant in flat and semi-gloss formulations, respectively.

Credit: BASF Corporation Credit: BASF Corporation |

| Table 6 Click to enlarge |

In the flat paint dispersion formulation, tint strength of the Pluracoat® CF 20-containing system matches that of Sample A. The ∆E between the two additives is negligibly small, i.e., 0.08. The hiding power K-∆E values are 0.18 and 0.25 for Sample A and Pluracoat® CF 20 respectively, and are well below the 1.0 acceptable standard. The Rub Out coefficients (RO) have small negative values indicating small if not insignificant pigment float to the surface of the coating.(5) Furthermore, ∆E measurement between rubbed and unrubbed coating areas, listed in Table 5 as ∆E(RO), confirm that the changes caused by sheer forces are only marginal.

In semi-gloss paint dispersions, the tint strength of the Pluracoat® CF 20-containing system differs from that of Sample A by 0.8. This could partly be interpreted as a slight improvement of the dispersing power of Pluracoat® CF 20 and partly could be attributed to the accuracy of the measurement. The ∆E between the two additives is also negligibly small, i.e., 0.1, indicating once again a match of pigment dispersing powers of the additives. The hiding power K-∆E values are 0.09 and 0.18 for Sample A and Pluracoat® CF 20 respectively, well below the 1.0 acceptable standard. The RO results have positive values, 2.10 and 1.36, indicating TiO2 float to the surface of the coating.(5) Despite the relatively large RO values, ∆E measurement between rubbed and unrubbed coating areas, listed in Table 6 as ∆E(RO), indicate that visual changes are small and not significant, since ∆E values remain well below 1.0.

Credit: BASF Corporation Credit: BASF Corporation |

| Table 7 Click to enlarge |

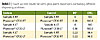

The touch-up test, and specifically low-temperature touch-up, has been designed to mimic real life application conditions. Albeit being a poor predictor of actual performance of the formulation, this remains one of the most challenging tests to pass. Typical touch-up test consists of two coating applications over a period of 24 hours. After allowing a first layer to cure overnight, the second coating is applied partially overlapping the first one. The color readings are taken to compare the areas coated with one and two layers. Some variations of this method could be adopted allowing one or both layers to be applied and cured at low temperatures. The results of these tests, conducted for semi-gloss paint at room temperature (RT) and low temperature (LT) conditions, are presented in Table 7.

The results of the touch-up study indicate that pigment dispersion properties are equally well developed in the presence of either Sample A or Pluracoat® CF 20. Thus, when the first and second layer of coating are applied at the same condition (first set of data at RT and second set of data at LT), the ∆E and Tint Strength (CREL) results show no difference between one and two layer coating. However, when the first layer was applied at RT followed by the second coat at LT, a slight increase in ∆E (up to 0.22) is accompanied by reduction of tint strength (down to 98.4 and 98.5). While this is a clear performance limitation, both Sample A and Pluracoat® CF 20 exhibit similar behavior, indicative of fundamental formulation issues rather than issues related to the dispersing additive.

Conclusion

Pluracoat® CF 20 was developed as an effective and environmentally compliant deflocculating dispersing and wetting additive. This zero-VOC and alkyl phenol-free surfactant has proven to perform as a suitable replacement for Sample A in a number of aqueous-based dispersant formulations with an added benefit of improved water sensitivity. As a multifunctional additive, Pluracoat® CF 20 allows the preparation of stable aqueous dispersions, providing a good opportunity to reformulate existing platforms to comply with low/zero-VOC regulations and alkyl phenol ethoxylate-free requirements.

For more information, visit www.basf.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!