UV-Curable Anti-Fog Coatings

At certain temperature and humidity, water vapor in air condenses on solid surfaces. Because water has much higher surface energy than most solid surfaces, the condensed water usually takes the form of small droplets, which scatter light and cause haziness. Fogging is a severe problem for a lot of optical devices, such as lenses, mirrors, windshields and visors et al. Basically, there are two ways to avoid hazy water condensation. One is to control the temperature and humidity so that water condensation can not happen.

For example, some devices use heating elements to keep the temperature high enough that water cannot condense; some devices are purged by inert gases or dry air to remove moisture. These approaches are very effective, but consume energy and they are expensive. The other approach is to use anti-fog coatings on the optical devices. Anti-fog coatings can prevent hazy water condensation and maintain the optical clarity. Obviously, this is a better approach, because anti-fog coatings are cheaper and consume no energy to operate. Considering the anti-fog mechanism, it is possible to categorize anti-fog coatings into three types.

Type I: The coatings remove water condensation by absorbing liquid water into the coating. Type I coatings can be saturated when moisture level is too high, and do not respond to water condensation quickly; therefore they are not very effective.

Type II: The coatings lower the surface energy of water, and the condensed water evenly wets the surface. Usually, Type II anti-fog coatings carry extractable surfactants.(1) When water condenses on the coating surface, the surfactants dissolve into the liquid water and bring down its surface energy so that water will wet the surface evenly. Type II coatings work effectively as long as enough surfactants can be extracted into water; however, surfactants can be washed away by water, and Type II anti-fog coatings will lose their anti-fog property gradually. In addition, because it takes time for water to dissolve surfactants, Type II coatings will not respond to water condensation very quickly. When suddenly exposed to high humidity, some Type II coatings can immediately get fogged and it will take some time for them to turn clear.

Type III: These coatings have a super-hydrophilic surface. Water has a very low contact angle, less than 5°, on superhydrophilic surfaces, and water condensed on a super-hydrophilic surface will evenly spread out very quickly. No surfactants need to be extracted from the super-hydrophilic coatings; they work instantly with little delay time. Super-hydrophilic coatings(2) perform better than the other two types of anti-fog coatings.

In this paper, we discuss UV-curable super-hydrophilic anti-fog coatings. UV-curable anti-fog coatings(3) can be cured instantaneously. They consume less energy to produce and, more importantly, they can be produced in a roll-to-roll process at high speed.

Experimental

Silica nanoparticles, as a 10-15 nm particle size, 30% dispersion in methanol, were used either directly without modification or were modified by polyethylene glycol-modified silane and acrylate/methacrylate-modified silanes.

Synthesis of Polyethylene Glycol-Modified Silane

|

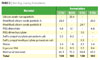

| Table 1 Click to enlarge |

Monomethyl ether polyethylene glycol (mPEG) (Mw = 1100) was dissolved in toluene and the mixture was dried. At room temperature and under nitrogen, a molar equivalent (with respect to the mPEG) of 3-isocyantopropyl trimethoxysilane was added drop wise to the reaction mixture. A few drops of dibutyl tin dilaurate were added as a catalyst. The reaction mixture was then stirred continuously for 24 h at 50 ºC. The reaction was monitored by infrared spectroscopy; the isocyanate signal is at 2271 cm-1. Upon completion, approximately two thirds of the toluene was removed by rotary evaporation and the mPEG trimethoxysilane was precipitated into hexane and washed several times. The resulting solid was dried and characterized by 1H NMR. Reaction yields of > 90% were obtained.

Silica Nanoparticle Surface Modification

The surface of silica nanoparticles was functionalized with mPEG triethoxysilane and 3-(trimethoxysilyl)propyl acrylate or 3-(trimethoxysilyl)propyl methacrylate. Table 1 shows the amount of each component used in the reaction. The mixtures were stirred at room temperature overnight to finish the reaction.

Coating Formulation

|

| Table 2 Click to enlarge |

Formulations were prepared by mixing modified or unmodified silicon oxide nanoparticles with reactive diluents, polyethylene glycol diacrylate (Mw = 575 g mol-1), sulfopropyl acrylate potassium salt, and a photoinitiator, 1-hydroxycyclohexyl benzophenone. The sulfopropyl acrylate potassium salt was added as a solution in water. The exact weights used for coatings are shown in Table 2. All the liquid coatings have a solid content of about 12%.

Coatings were applied on PET or polycarbonate sheets using #16 wire wound rod. The coatings were dried for half a minute, and then cured under a 300 W per inch mercury vapor lamp at a dose of 1 J/cm2 in a nitrogen atmosphere. The thicknesses of the cured coatings were about 5 micrometers. The coated samples were characterized by cross-hatch adhesion test, pencil hardness, optical properties and steel wool scratch test.

Results and Discussion

|

| Table 3 Click to enlarge |

All cured coatings have 100% adhesion on treated PET and polycarbonate substrate, 99% optical clarity and over 90% transmittance. The anti-fog properties of the coatings were tested by holding a coated substrate for 15 seconds above warm water at 50 °C. The coating performance is rated to the degree of fogging/transparency. If the coating fogs completely, having no transparency, it is rated as 1. If the coating does not fog at all, staying completely transparent, it is rated as 10. A complete description of the rating and degree of fogging is given in Table 3.

|

| Table 4 Click to enlarge |

Anti-fog performance of coatings is listed in Table 4. All the coatings with the sulfonate salt have perfect anti-fog properties; the coating without sulfonate salt has poor anti-fog properties. Typically, ionic groups are more hydrophilic than ethylene glycol groups, and that is probably the reason that coatings containing sulfonate salt have better performance in the fogging test.

Because all the components are crosslinked into a polymer network, after the coatings were washed by water their anti-fog performance did not change. It also has no effect on anti-fog performance whether acrylates or methacrylates were used. However, methyacrylates polymerize much slower than acrylates. When coating E is cured in air, the coating is very tacky because of the oxygen inhibition. There is no obvious difference between coating C and coating E, when they are cured in nitrogen.

The modification of silica nanoparticles has no effect on anti-fog performance of the coatings. Because the modified silica nanoparticles are covalently linked into the polymer network, the modified silica nanoparticles should give the coating better scratch resistance. Since silica nanoparticles without modification can already give good mechanical properties, surface modification of silica nanoparticles is not always necessary.

|

| Figure 1 Click to enlarge |

The coating with non-modified silica particles was applied by a roller coater on flexible PET and polycarbonate sheet. The coating was applied and cured continuously at 5 m/min in a roll-to-roll process. As shown in Table 5 and Figure 1, the coated transparent sheets have good optical and mechanical properties and uniform thickness.

|

| Table 5 Click to enlarge |

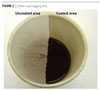

Anti-fog coatings were also tested at both high and low temperatures, and they worked very well between -20 ºC and 90 ºC. As shown in Figure 2, a piece of partially coated polycarbonate plate was placed on a cup of 90 ºC coffee. The plate was initially at room temperature. When it was exposed to the moisture from 90 ºC coffee, the uncoated area was immediately fogged, while the coated area always stayed clear. In the low-temperature test, the coated samples were cooled down to -20 ºC, and then were exposed to 60% humidity room temperature air. The coated area stayed clear, while the uncoated area was quickly fogged.

|

| Figure 2 Click to enlarge |

Conclusion

UV-curable anti-fog coatings were developed. The coatings comprise inorganic nanoparticles and UV-curable hydrophilic materials. The coatings can prevent fogging at temperatures between -20 ºC and 90 ºC. The coatings show excellent optical clarity, good hardness and scratch resistance.

This paper was presented at the RadTech 2010 Technology Expo and Conference, Baltimore, MD, www.radtech.org.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!