Foam-Control Solutions That Meet Today's Tighter Environmental Regulations

Foam control has always been a challenge in the coatings industry. Unlike many other industries that only need to control foam during the manufacturing process, coatings must be designed to perform over a potentially long product shelf life so that the end user can open a can of paint and apply it without bubbles that can contribute to defects in performance and detract from the overall appearance. The need for short- and long-term efficacy is a challenge, as defoamers are often formulated to prevent production or application foam, but not both. In recent years, this challenge has been magnified as coatings formulations evolve in response to stricter environmental standards that limit the level of VOCs.

|

| Figure 1 Click to enlarge |

As the industry continues to move toward low- or zero-VOC coatings, there is an increased tendency to form micro foam, a more stable foam that is more difficult to eliminate. In addition, shorter open times in these formulations require defoamers to be more fast-acting. Raw material suppliers and coatings manufacturers need to stay one step ahead of the regulations and market trends in order to design products that are acceptable and provide effective solutions ready to match changing market needs. What worked yesterday may not necessarily work as effectively with today’s newer formulations.

The good and bad news for coatings manufacturers is that, today, there are more choices in defoamers, including synthetic-based, organically modified silicones and enhanced mineral oil-based products, to mention just a few. This means there is a better probability of finding a defoamer that meets a specific need and application. Unfortunately, it also means additional evaluation and testing may be required to confirm compatibility with a chosen defoamer. This article is designed to make that process easier and more methodical, and to review some of the newer chemistries on the market, as well as their capabilities.

Foam Control

The foam-control agent can work as an anti-foam to inhibit the formation of the lamella or as a defoamer, which disrupts the lamella once it has formed. In a coating, these actions must be completed and the surface allowed to re-level prior to drying to avoid defects. The three primary components of the foam-control product drive these actions. Table 1 lists some of the common ingredients used as primary components. The various combinations of these diverse chemicals present an almost infinite number of options for manufacturers today. This large number of options, while potentially confusing for the formulator, is necessary given the number and nature of components in today’s coatings.

|

| Table 1 Click to enlarge |

Looking more closely at the three main components of the average defoamer, the primary function of the liquid vehicle is to aid in the introduction of the active hydrophobe into the liquid media. The emulsifier/spreading agent, as the name implies, facilitates hydrophobe spreading and can adsorb at the air/water interface of a bubble and, hence, displace some of the bubble-stabilizing surfactants that aided or caused foam formation. The hydrophobic particles integrate into the outer bubble wall to create areas of localized de-wetting. This mechanism helps to form gaps and rupture bubble walls, thus aiding, to some extent, the prevention of foam reforming.

Every ingredient found within an individual defoamer has a function, whether it is to assist in spreading, drainage for thinning or lamella rupture processes, preservative properties, product stability, quick bubble break, or let-down stability, to name a few.

Defoamer Choice - Meeting Today's Challenges

Foam in modern coatings is often more stable and harder to control than in prior coatings systems. Higher-VOC coalescing aids often, unknowingly, were mild defoamers themselves. Their use, however, is being phased out, and newer replacements that meet the lower-VOC requirements, unfortunately, do so at a price – with more foam being generated in a more stable form.

Coatings formulations can utilize hundreds of choices of resins, pigments, fillers, dispersants and many other functional ingredients. Their characteristics can differ greatly with respect to surface charges, hydrophobicty/hydrophilicity (HLB), the presence of aromatic, linear and/or polar groups, and pH and other variables, all of which impact solubility and compatibility of potential additive choices.

As a result, no single defoamer is appropriate for all applications. When determining which defoamer will work best, it is critical to identify one with a liquid phase that has a degree of incompatibility with the coatings media into which it will be dosed, as well as a rapid spreading coefficient. And, since the hydrophobic particle works on a semi-specific contact angle, it must be the correct size and shape for the nature of the foam. The size, shape and thickness (viscosity) of the foam, and the media, impact the foam stability, as well as the gravity and capillary forces of the interstitial space between the lamella walls. This will dictate the mechanism necessary to break the bubbles. In fact, the capillary forces are greatest in microfoam where the diameter of the interstitial spaces is the smallest, presenting a greater challenge.

An additional challenge for coatings today is that low-VOC formulations have shorter open times because they dry quicker – as fast as 30 to 60 seconds instead of the five minutes it took for higher VOC formulations to dry. This means the defoamer must meet an extremely rapid bubble break time. The increase in popularity of spray coatings decreases the open time even more.

The products and preferences being demanded by the end users are also changing, in turn impacting the defoamer choice for the coatings manufacturer. For example, industrial and wood coatings manufacturers are being asked to create more clear coatings. These coatings present the challenge of selecting a defoamer that not only eliminates foam but also maintains the clarity of the system. Often, effective defoamers can cause a haze in clear coatings due to their inherent incompatibility with the system.

In the paint category, there is greater demand for high-gloss (shiny) finishes, which are more prone to generate microfoam. Accent walls with high pigment concentrations have also become trendy. As more colorants are added, the amount of foam also increases. Such design trends can greatly impact how the products are being used, as well as the amount of foam they generate.

Semigloss paints tend to create the greatest foam-control challenge. Older defoamers on the market inherently knock down gloss, creating an unacceptable flat look. Newer chemistries are often required to control foam without removing the gloss.

Although there actually may be a number of defoamers that can produce moderately effective results in a formulation, choosing the optimum one requires answers to a few basic questions:

- Is the defoamer compatible with the system and product? In other words, does it have any adverse effect on the appearance or quality of the finished product? Are there specific constraints, i.e., gloss, clarity, ease of incorporation that must be met?

- How efficient is the defoamer? That is, how much of the defoamer is needed to control foam (low dose or high dose)?

- Is the product being used for an interior or exterior application? If it is exterior, there might be different wetting agents or anti-fungal additives.

- Is the product designated for food contact? What FDA regulations must be met?

- Is the product being used in an application that requires no- or low-VOC content? If so, not only does the chosen defoamer need to meet the low-VOC requirements, but it must also be able to overcome the challenges of working with other low-VOC additives. In general terms, the lower the VOC content the greater the foam-control challenge.

- What is the application – spraying, brushing, dip coating, etc? The shear rate applied in each application differs and greatly influences the defoamer selection.

- What is the nature of the foam-control issue? Is it during production or during application? If it’s happening in production, it requires quick foam control. If the end user is complaining, a defoamer with improved aging ability might need to be considered.

- Is temperature an issue? Thermally cured coatings require additives with higher flash points.

- How much does it cost? The upfront price-per-pound is only one piece of data and not the most important one. What matters most is the actual usage cost (also known as the value in use). If you switch to a newer-generation product, you may likely reduce the usage level and overall cost, even if the purchase price is higher.

|

| Table 2 Click to enlarge |

Newer Foam-Control Solutions

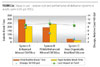

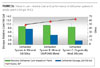

The dramatic increase in the cost of base oils used in the manufacture of many popular lower-cost defoamers has significantly changed the view of foam-control costs. Take, for instance, the results seen in Figure 2 of three different foam-control systems on a 100% acrylic <50 g/L VOC architectural coating. The higher cost per pound for the defoamer alone (System C) surprisingly had a slightly lower cost impact, on average, on a gallon of paint than the other two systems due to its high efficiency. System C required much lower levels to provide highly effective foam control as shown in Figure 2a.

|

| Figure 2a Click to enlarge |

Conclusion

As this article has demonstrated, choosing the right defoamer requires in-depth technical knowledge and consideration of the value in use of the product. So the decision to use a specific defoamer should be based not only on the product’s capabilities, but also on the seller’s ability to provide technical support, resources and advice. Beyond the obvious product questions already addressed, it is also important to ask a few questions of your supplier.

- Does the company have an in-house lab?

- Is there capability for the supplier to screen and test products?

- Can the supplier provide technical service such as ladder studies to aid in defoamer selection and determine the minimum level that can be used to still achieve optimal results?

|

| Figure 2b Click to enlarge |

With the right defoamer and the right supplier, you should be able to save money, meet current EPA regulations, minimize customer complaints and achieve greater aesthetics in your end product.

For more information, visit www.emeraldmaterials.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!