Shedding the Abatement Burden

Many plants are struggling with the problems presented by VOC abatement systems. These problems include the initial investment, which adds no value to the end product, the cost to operate and maintain the system, and the challenge of quickly responding to emergencies that risk shutting down entire production facilities. Additionally, plants face the problem of maintaining and, under Title V, continually verifying compliance.

Under these circumstances, it does not make sense for an industrial plant to use its own personnel to operate and maintain VOC abatement systems. Maximum efficiency is realized when responsibility for abatement is outsourced to an abatement-system expert.

VOC abatement systems present several risks to the profitability of any plant:

Compliance risk-Will the abatement system achieve the necessary destruction efficiency? Will low efficiency result in a fine or, worse yet, the closing of a plant?

Operational risk-Will the equipment in the abatement system fail, forcing production to stop?

Monetary risk-Is the system operating at peak efficiency, or is the company wasting money on natural gas, electricity or premature equipment overhauls?

New-technology risk-Operating costs can often be reduced and system maintenance better executed with new technology. Outsourcing contractors are often able to manage the risks of new technology more effectively than industrial users.

Minimizing the risks

These risks, taken in total, lead to an important question: If a plant is not in the environmental business, then why is it paying plant personnel to do occasional environmental or safety activities that could be outsourced to experts?

An abatement contractor will typically monitor system performance by metering utility consumption, monitoring equipment variables such as temperature and vibration, trending operating parameters and simply observing the equipment on-site. Extensive data collection and subsequent statistical analysis, followed by the appropriate response, will provide a reasonable assurance of compliance.

Abatement outsourcing, when structured correctly, will decrease the cost of owning and operating an abatement system because the contracts are typically based on a monthly cost tied closely to guaranteed performance. Any utility overruns or unexpected equipment repairs are the responsibility of the contractor.

Companies have been reluctant to outsource critical functions such as abatement, fearing that reliance on an outside contractor could put the plant in a vulnerable position if something should go wrong. While many skeptical managers fear a loss of control over key equipment or systems, outsourced operations actually offer greater control over plant success through enforceable performance standards, which are based on regulatory requirements that must be met before a contractor is paid1.

In-house staff may not be able to provide the benefits outside contractors can offer, including focus, expertise and system upgrades.

Focus-The primary benefit offered by an abatement contractor is focus. The plant and its staff are focused on getting the product out the door and keeping the production equipment operating. An abatement contractor has no focus on the client's production; its only focus is the abatement system.

Expertise-A second advantage a contractor can offer that in-house resources cannot is expertise. Because manufacturers have an intimate knowledge of their systems, they are well positioned to perform operations and maintenance with greater efficiency, focusing on the detailed service needed to realize incremental increases in efficiency.

System Upgrades-Capital expenditures to implement new technology will often increase uptime or decrease operating and maintenance costs. If a simplified payback of two years or less is required for capital expenditures, many worthwhile technology improvements will not be implemented. When capital expenditures are financed over the life of the long-term contract, the resulting monthly savings can often offset the monthly capital burden.

Because of the different evaluation criteria, outsourcing contractors can install system upgrades that would otherwise not be implemented.

Elements of a successful outsourcing program

To outsource abatement, a firm will contract with abatement experts who assume complete responsibility for operation and maintenance of a plant's VOC abatement system.

"Assumption of complete responsibility" is crucial. A successful outsourcing program does not simply bundle system installation with service as a packaged product. The outsourcing contractor must assume responsibility for compliance and costs in order to maximize the benefits to both parties.

The contractor should:

• Operate and maintain the system

• Monitor all aspects of the system's performance to ensure compliance

• Report clearly and regularly to the client about the status of the system and its compliance

At least one commercially available program provides these additional services:

• Guarantees compliance and equipment for up to 10 years

• Guarantees decreased cost of owning and operating abatement equipment, compared to the costs the company would incur by operating the equipment itself

• Financing the abatement equipment over the life of the contract, up to 10 years

To ensure an effective abatement outsourcing program, a contract firm should provide a local field staff 24-hour-a-day monitoring and operate under a contract structured so that the interests and motivations of the client and the contractor are closely aligned. This will achieve compliance, system uptime and cost efficiency.

Financial considerations

The monthly payment for an outsourcing contract should be very well defined and based on measurable variables such as uptime, air volume, metered utility consumption and destruction efficiency. The predictable nature of the payment means that the plant can accurately plan operating budgets without fear that an unexpected occurrence will result in budget overruns.

The defined payment will likely fluctuate, not because of unexpected events, but as a result of changes in operation. Payment changes will typically result from factors such as changes in air being treated, bonuses paid to the contractor for exceeding stated goals or penalties deducted from the vendor's payment for failing to meet minimum standards.

Changes in metered consumption, such as natural gas or electricity, should be the responsibility of the contractor whenever possible. Placing the utility-consumption burden on the contractor removes the risk that overly optimistic utility predictions will not be realized and that excessive utility consumption will impact the plant's budget.

Based on the efficiencies that an abatement expert can realize in utility consumption, ongoing preventive maintenance and advanced diagnostics, the contractor can reduce the cost of abatement. System upgrades, continuous optimization and fine-tuning and statistical analysis offer further opportunities for saving money.

Beyond the documented savings, intangible, though very real, benefits are attained. Spare-parts inventory and carrying costs are no longer incurred. Staff training and retraining are no longer needed. The carrying costs associated with warranty funds for unexpected repairs are no longer incurred. Most significantly, the consequential damages of lost production resulting from abatement system downtime are reduced or eliminated.

Determining the current cost of operations and maintenance is the first step in determining whether an outsourcing contract will in fact reduce the cost of abatement. Though this appears simple, most plants don't know the complete costs, or they haven't fully quantified what the true costs are.

Figure 1 shows how all the elements of owning and operating an abatement system add up. These data are based on actual regenerative thermal oxidizer (RTO) installations and may not apply to every installation. However, these or similar costs are commonly incurred in various forms for most systems. When outsourcing is evaluated and compared to the complete cost of abatement, it is important to consider and quantify all costs associated with the system, including often-overlooked costs such as carrying costs of spare parts, added overhead, subcontracted skills and the cost of lost production or lost opportunity.

Case study

Dürr Environmental has had a comprehensive outsourcing program in place for several years. Several satellite offices have been established in industrialized areas to operate abatement systems and assume responsibility for maintaining compliance. Several plants in Ohio have contracted responsibility for their abatement system's compliance and are currently working with the abatement contractor.

The following is a summary of the operation, the data collection and an explanation of how compliance is being certified.

Each plant involved with the abatement contractor has a regenerative thermal oxidizer (RTO) system. To establish baseline conditions before the contractor assumed responsibility, plant records were used to determine the historical cost of operating and maintaining the system; meters were installed to verify utility consumption.

Complete responsibility for system compliance certification, operation and maintenance has been outsourced to Dürr. As part of the executed outsourcing contract, the RTO was upgraded at no upfront cost to the plant. Even with the cost of the upgrade rolled into the contract, the base monthly payment for the contract is about 95% of what the plant had been paying. All utilities consumed are the responsibility of the contractor, imposing a clear and certain motivation for it to maximize efficiency over the life of the contract.

A 10-year warranty has been provided on the four-year-old RTO. The plant no longer has to maintain an inventory of spare parts. No longer is it necessary for the plant to staff or train new employees to operate and maintain the abatement system.

Regular site inspections are conducted from the satellite office to verify performance, identify conditions that might lead to noncompliance and execute a preventive maintenance program to reduce long-term system costs.

Compliance monitoring

Under the current laws, plants are to remain in continuous compliance. Any corporate official, as well as the enforcement agencies, can use any credible evidence of compliance or noncompliance, such as monitoring information, inspections or testimony of employees to verify compliance status. It had previously been assumed by many that only the results of EPA reference tests could be used to prove compliance or violations. Current rules and laws make clear that this is not the case.

Companies must now operate with a monitoring plan that should ensure abatement equipment is operated consistent with good practice2. Certification of compliance must be based on monitoring that provides reliable data that are representative of complaince3. Together, these rules mean that now, more than ever, the plant needs to be proactive in ensuring it remains in compliance.

Data collection is not limited to measures of process variables collected by the control panel and stored by the server. In addition, the site manager collects data on equipment performance and preventive maintenance during regular site visits. Like the process variables used for statistical process control, this data is used to identify and resolve problems before they lead to noncompliance.

Data is collected and used as shown:

Basic data is used to monitor the basics. Is the combustion temperature at the correct set point? Are the airflow switches reading flow? Are the limit switches verifying valve operation?

Data analysis is used to draw conclusions from the collected data to predict compliance. For example, is the utility consumption near predicted, or has a change occurred, indicating the operation has changed? Are data points conflicting, indicating one of the variables is a false indication?

Maintenance data, which is collected during on-site system inspections, may indicate that equipment failure is imminent. Equipment failure will not only affect compliance, but could threaten to shut down the entire facility until resolved.

System optimization-Does the data indicate that the efficiency is less than optimum? Though compliance may not be affected, long-term inefficiencies can have a significant impact on costs, and eventually, any comprehensive measure of total performance.

Data analysis

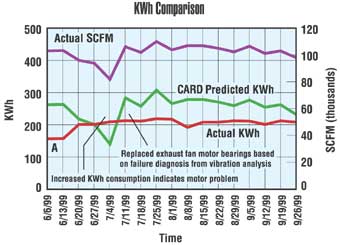

Figure 2 shows a combustion chamber temperature reading with two levels of upper and lower limits. A basic table like this will forewarn the manager, in sufficient time to avoid a noncompliant situation, should the temperature control wander much.An example of data analysis used to maintain compliance can be seen in Figure 3. The plot shows the airflow being treated, the predicted electrical consumption based on the airflow and the actual electricity consumption. Notice that at point A, the airflow decreased and, as expected, the predicted consumption decreased. But the actual consumption increased. This alone does not indicate what problem has occurred, but it is a flag indicating something has changed.

In this instance, this change prompted the site manager to do a detailed system review. A quick vibration analysis on the exhaust fan/motor indicated that the vibration had increased significantly since the last scheduled vibration analysis. The bearings were failing, meaning increased vibration and higher electrical consumption. During the next down period, the bearings were changed out and the vibration problem corrected.

The data trending, the vibration data collected during routine operation and the subcontractor on site combined to identify and solve a problem before the system reached noncompliance. Avoiding loss of production was a major additional benefit to the plant.

Data analysis also identified a faulty thermocouple, which was fixed before a noncompliant situation developed. During a period of steady airflow and consistent plant operations, the fuel consumption dropped noticeably. A system inspection revealed that the combustion chamber thermocouple was giving a false reading. The actual temperature was much lower than expected, resulting in a decrease in fuel consumption. Very quickly, the problem was corrected, the fuel consumption returned to normal and a situation that would have led to noncompliance was immediately resolved.

System Optimization

As part of a thorough outsourcing program, data collection is used not only for compliance certification but also for system optimization.

Figure 4 shows the natural-gas consumption relative to airflow during routine operations. The data indicates that with steady inlet conditions, actual consumption is also steady as expected, with minor fluctuations normal.

Figure 5 shows the actual airflow as a function of time, plotted with actual electricity consumption. This plot, too, should be steady. But by mid-June, the actual electricity consumption had begun to increase for no apparent reason, indicating the operation was not optimized.

At this point, a bake-out was performed. (A bake-out is a cleaning procedure for the oxidizer designed to remove any accumulated deposits that may be impacting operation.) The plot shows that the beneficial impact of the bake-out was short-term only. In the next few weeks, consumption rose even higher than before the bake-out.

Additional investigation showed that incorrect filters had been installed in the emission source, resulting in excess particulate load. The additional particulate quickly plugged the oxidizer. Installing the proper filters solved the plugging problem, as indicated in the table.

Historically, the particulate problem would have gone undetected until the RTO was completely plugged, exhaust from the process was limited and production was adversely affected. Only then would the filter problem have been solved. Unfortunately, by that time, a large amount of utilities would have been wasted, and the plant would have incurred lost production needlessly.

Maximum efficiency, whether measured in terms of utilities, on-line time or compliance, is often realized when responsibility for abatement is outsourced to an organization with specialized expertise. A successfully negotiated outsourcing contract puts the client and contractor on the same side of the business equation, closely aligning the best interests of both parties. Abatement outsourcing can offer an assurance of compliance certification that cannot be as economically developed and maintained in-house.

References

(1) Shelley, S. "Outsourcing's Rising Tide," Chemical Engineering, April 1997.

(2) Berry, J. "Legacies of the 1990 Clean Air Act Amendments," Industrial Paint & Powder, August 1998.

(3) Lobb, F.; Westlin, P. "Effective Engineering is Key to Title V Compliance," Environmental Management, October 1999.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!