Nu-Way Uses New Way To Decontaminate Wastewater

The company has a broad scope of service capabilities and a strong allegiance to technological advancement. And Nu-Way prides itself on its quality and range of services offered, technological flexibility, and seamless interface with customers throughout development and manufacturing processes.

As you might imagine, with such large volumes of steel being processed, the buildup of oil caused Nu-Way to dump and recharge their spray washer tanks every three months.

There are two automated lines at Nu-Way - the Green Line and the Blue Line, each named after its exterior color. The Blue Line runs at 8 fpm and can handle a part up to 36" wide x 48" high x 9' long. The Green Line runs at 10 fpm and can handle a part up to 48" wide x 60" high x 16' long.

The automated lines use six automatic spray guns mounted on rotary oscillators and manual spray guns from ITW Gema, Indianapolis. Spray booths are from Wagner Systems, Carol Stream, Ill. The application equipment is located in a clean, well-lit, environmentally controlled room for process control. The company has a very low turnover rate of employees who are 5S certified for their application. Finish quality is routinely measured and verified by a comprehensive set of in-house calibrated tools, including a light booth, gloss and thickness meters, and an environmental test chamber.

The batch operation was built in-house seven years ago. It features a closed-loop, hand-pull conveyor traversing the outer parts of the booths and a powered conveyor through the center of the booth. The batch system uses a high pressure spray wand system from Fremont Industries, Shakopee, Minn., that applies a cleaner/phosphate solution and a seal rinse for pretreatment, and can handle a part up to 16' wide x 15' high x 20' long.

Washing the Wastewater

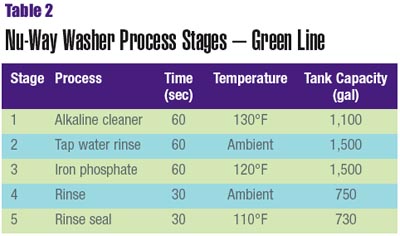

The spray washers that Nu-Way uses on its automated powder systems are five-stage operations with alkaline cleaning and iron phosphate treatment supplied by Chemetall-Oakite, Berkeley Heights, N.J. (Tables 1 and 2). Effective treatment chemistries remove soils and oil from the parts and retain them in the solution. As oils and solids build up in the solution, the cleaning and treatment capability of the solution gradually declines. Removal of the oil or solids on a continuous basis can extend the life of the solution, saving maintenance time and getting more value from the chemicals.

Spent, contaminated cleaner is pumped at relatively low pressure (typically less than 120 psi) across the surface of the membrane. Soluble materials larger than the membrane pore size (oils and suspended solids) are retained and concentrated within the Washer Washer's process tank, while water and low molecular weight constituents, like the cleaner's surfactant and detergent components, can pass through the membrane and return to the washer solution. The permeate that passes through the membrane leaves as a clear filtrate while the rejected fraction (oils and soils) is moved away continuously due to the turbulent flow at the membrane surface. As a result of this crossflow, the speed of processing (flux or flux-rate) across the membrane remains relatively stable when compared to traditional "dead-end" filtration. Flux decline is slow and steady, with typical runs lasting from two to 10-plus weeks before the system requires attention.

The process begins by gravity transfer of dirty cleaning solution from the washer solution to the Washer Washer's process tank. The process begins as a modified batch, meaning that during the initial phase of the cycle, the process tank is kept full to minimize concentration of contaminants. The operator empties the Washer Washer's process tank, then refills it from the washer, exchanges the dirty membrane module with the spare if required, sends the dirty one to Arbortech for cleaning (or cleans the membrane module in-house) and begins recycling again.

Sizing Criteria

The objective of this system is to recycle enough cleaning solution on an average-per-day basis to turn over the total wash bath volume four to six times before the end of the customer's historically established cycle for dumping and recharging. This turnover rate has proven sufficient for keeping a washer's level of contamination in good control. In other words, with a quarterly dumped 1,500-gal wash bath, the math is as follows.

Tank size: 1,500 gal

Historic dump cycle: 90 Days

1,500 x 6 (to be conservative vs. 4 turnovers) = 9,000

9,000 ÷ 90 = 100 gal/day

This is a preliminary calculation to serve as a starting point and assumes that separation can be made continuously and the membrane recovered and cleaned repeatedly without loss of performance or damage from exposure to the dirty cleaner streams.

Following the initial bench scale demonstration in late January 2003, a pilot study began on one of Nu-Way's two five-stage washers in March 2003 on the Green line. The 1,100-gal first-stage cleaner tank has an alkaline cleaner with a 3 percent concentration of Gardoclean S5219, at an operating temperature of around 130°F and a pH of 8.5 to 9.5. Arbortech brought in its pilot scale WW1 Series system with heater package and Nu-Way placed the membrane module directly into the side tank where it "weeps" the recycled cleaning solution back into the wash tank. The pilot unit required a 20 A, 110 V single-phase line for the circulation pump and, if used, a second 15 A, 110 V single-phase circuit for the immersion heater. A learning curve followed, during which they found that a prefilter would be required to keep the Washer Washer's circulation pump in good running order. Solids buildup in the pump had initially caused unacceptable pressure changes.

The flow rate of treated water to be recycled, referred to as permeate, increases as temperature goes up. When the Nu-Way process tank heater is in operation, the flow rate of permeate is satisfactory. When the washer solution heater is not in operation (weekends or at night), the heater provides adequate temperature elevation to keep things running well.

Prior to installing the Washer Washer system, Nu-Way's high levels of zinc and FOG (fat, oil, grease) in the cleaner and other process tanks in their washers made the company unable to discharge untreated water, which forced them to consider options for treatment. Joe Bappert, facilities manager at Nu-Way, says that they chose the Washer Washer as an alternative to a waste treatment system that would have cost more than $150,000 and taken up considerable floor space with no return on investment. Among the benefits of operating the Washer Washer, he says, "We not only trapped the oils in solution, we also significantly reduced the zinc count in our tank solution."

Nu-Way measured the FOG and zinc levels in the tank solution and in the concentrated waste from the filtration system to determine the specific changes in the operation. Prior to using the Washer Washer system, zinc counts were as high as 220 mg/L and FOG levels as high as 1,330 mg/L in the wastewater. Nu-Way measured the concentrated waste from the filtration system and the tank solution and found that the tank solution had been reduced to 6.39 mg/L of zinc and 555 mg/L of FOG, while the concentrated waste was at 231 mg/L of zinc and 3,950 mg/L of FOG. In addition, the sludge buildup in the washer tank was much lower, extending the bath life from three months to six months and reducing maintenance significantly.

"Our turbidity in the tank is lower, process operators find it much easier to clean the tank, we have better bath quality, and we have improved the bottom line," says Bappert. Zinc levels had prevented Nu-Way from discharging its overflow, but now they have no problem and their makeup water volume is only 5 gpm. Although zinc was not a primary target of the system, it turned out that enough of it gets tied up in the oil removed from the washer solution to keep the cleaner and the rest of the washer much lower in zinc levels.

One Hand Washes the Other

Arbortech has further strengthened its business partnership with Nu-Way. The process tank mounting bases are now fabricated and powder coated by Nu-Way, a good indicator of the value of the equipment and the level of customer satisfaction.The Washer Washer system also can be used to clean floor wash water by recycling the wash water offline. Arbortech has more than 100 units in operation since introducing them in 2001. In addition to cost savings, simplifying the operation and improving environmental compliance are good reasons to look into oil removal and other filtration options.

For more information on the Washer Washer, call Arbortech at 815-385-0001 or visit www. arbortech.com. For information about Nu-Way, call 847-298-7710 or visit www.nu-way.net com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!