Moving On Up: From Grain Elevators To Turnkey Manufacturing

Grain Belt has since grown into a company with turnkey manufacturing services from development to finished product. It performs product design, short or long runs, prototype development, laser cutting, rolling, welding, bending, cutting, shearing, drilling, tapping, punching, sawing, stamping, forming and shipping. Manufactured products still include grain elevators, but it also makes a range of metal fabrications and laser cut product.

During the boom years of the grain elevator business, there were several different elevator builders and Sampson had some difficulty in purchasing the metal components required for his products. When he bought into Grain Belt, he set it up to manufacture steel parts for the elevator business. He was planning to manufacture the steel parts that would be needed to replace wear parts from the grain elevators that he and other companies had built during the boom.

Grain Belt has purchased a total of eight CNC lasers since 1997. The result of this investment was to take the company from "a blacksmith shop" to a quality manufacturer that could make a part in virtually any geometric shape with a tolerance of ±0.005". But there was still work to do. After the parts were cut with the new lasers, they were taken to the old press brake where they were bent to a 90° angle that could be off by 0.625". "We very quickly decided that CNC press brakes were required so that we could match the laser tolerances in the bending stage, and now we utilize five CNC press brakes in our fabrication operation," says Wingo.

In researching options for a new finishing process, Grain Belt began talking to powder coating system suppliers and determined that a state-of-the-art powder coat system could be used to coat virtually any part size, cure parts from 20 gauge to 1" plate, remove the laser scale residue on the edges and allow them to change colors on small runs in less than 10 min. This would round out their services and raise everything to the level of quality that they had been trying to achieve since purchasing that first laser-cutting machine.

After a year of research, Grain Belt decided to work with Spray Booth Systems (SBS), Ft. Worth, Texas. The new powder system includes a seven-stage stainless steel washer, a dry-off oven, a powder booth with two manual spray openings and automatic gun slots, a cure oven, a conveyor system and controls. The powder system is designed to handle a maximum part size 3 x 5 x 10' long at 6 fpm. The building that the system is installed in is approximately 25,000 ft2 and has three load docks and large overhead door for smaller trailers.

Grain Belt is a manufacturing job shop so it cannot predict the size of parts that it may be asked to fabricate. For that reason, it also included a batch operation that can handle large parts up to 8' wide x 40' long. Batch coated parts are cured in the same oven as the automated line. The batched parts are coated on a cart that is wheeled into the oven through a large door built in one the oven walls.

Pretreatment System

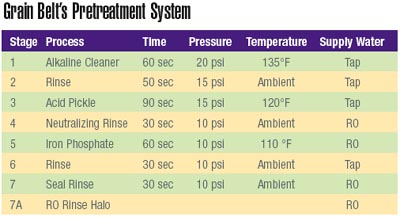

The all-stainless-steel washer has an alkaline cleaning stage, a rinse, phosphoric acid pickle, rinse, iron phosphate, rinse, a final seal rinse and a reverse osmosis (RO) halo rinse at exit end of the washer. The entire washer is built of type 304 SS except for the final two stages, which are type 316 SS. The water used for the final rinse halo and for makeup in the washer comes from an RO system supplied by R3 Technologies Inc., Pearland, Texas. The washer is designed to provide good results on a range of substrates and combine with powder coating material to achieve 750 hr of salt spray resistance. Grain Belt offers the addition of a powder primer where situations require even greater corrosion resistance.

The chemistry used in the washer, supplied by Chemetall-Oakite, Berkley Heights, N.J., includes an acid pickling stage to remove the oxide layer from the edges of laser cut steel components. Laser oxide is an ongoing problem for powder coaters because the adhesion of the oxide layer is relatively loose. If the edge is broken by mechanical force the powder may rapidly lose adhesion along the edge. The pickling stage also provides effective removal of stains and carbonized oils in welded areas and removes mill scale on hot-rolled steel parts. A rust inhibitor is used in stages 4 and 6 to prevent flash rusting.

Wastewater Treatment System

One of the key concerns for Grain Belt was an effective and affordable waste treatment system for the wastewater from the spray washer. R3 Technologies offered a fully automated system that could treat all of their wastewater with a minimum of labor and very low hourly operating costs.Wastewater is collected at the end of the washer in a large pit. The water is then transferred for batch treatment in two 3,000-gal holding tanks with agitation. The batch of wastewater is then passed through an oil separator that will allow oils to float to the top and solids to settle to the bottom before the water stream enters the precipitation system. Solids are transferred to a filter press for dewatering.

The wastewater stream is gravity-flowed to the precipitation system from the oil separator. Two agitated pH adjustment tanks are used to add acid or sodium hydroxide for pH adjustment to around 8.5, the optimum pH for precipitation of most heavy metals. After 20 min of contact time, the water stream flows into a polymer mixing cell where coagulant is added, causing a heavy floc to form, carrying the heavy metals out of solution.

The flow moves on to an inclined plate clarifier for sludge settling. The treated water flows over a weir to an outflow tank where the final pH is recorded before the water is released to sewer through a meter that records the flow rate. The sludge is removed to the filter press where it is pressed into a semi-dry cake for disposal. The water that passes through the press is returned to the holding tank for reprocessing.

Quick-Change Powder Booth

After the parts have been pretreated and dried, they enter the powder coating booth. Grain Belt chose a Nordson ColorMax booth for its operation. The features of the ColorMax combine to minimize powder-in-process, ease booth cleaning, and provide fast powder-supply-system changes. The non-conductive booth construction minimizes powder retention inside the system during operation so there is a very small amount of powder to clean up during color change. Hinged cyclone sections provide easy operator access for inspection and easy cleaning. The air distribution system uses high air velocities over 140 ft/min (0.7 m/sec) to ensure improved powder containment in the air stream. Air knives in strategic locations inside the booth help reduce powder-in-process for maximum recovery efficiency and reduced color change time. No inlet ductwork into the cyclone provides easy visual inspection of areas of the system that could cause contamination between colors. The Sure Coat gun control system includes a select charge circuit that allows the operators to select application-specific coating modes for recoats, Faraday cage areas and inside recesses.The ColorMax system substantially reduces labor cost, downtime and material waste in a multicolor powder coating application such as Grain Belt. The operating flexibility allows the company to manage smaller batches and a wide range of colors to fit just-in-time production schedules.

The booth is equipped with automatic gun slots so that Grain Belt can add them if future volumes require more guns. The entire application process is enclosed in an environmental room to limit the influence of climate changes during the different seasons of the year and provide a clean, low humidity atmosphere.

SBS integrated an infrared boost oven at the entrance of the convection cure oven that provides the needed flexibility for the various gauges of metal. The system is designed to cure heavy gauge material in 22 min by application of infrared energy at the beginning of the cure cycle. The coaters can choose from one of four recipes on a console that is mounted on a stand by its application platform. The console is wired back into the main computer that is programmed with the recipes.

For example, the lead coater sees a large, complex gate that weighs 400 lb, constructed of 0.1875" thick steel with several parts welded on to the structure. He chooses recipe No. 2, which is 50 percent of total power on the infrared heat boost. The infrared oven provides the needed energy boost to rapidly bring the part surface temperature up to 320°F. The convection time in the oven is the same for the heavy part as it is for lighter gauges. The oven infrared boost panels are from Protherm, Brandon, Minn., and the controls are SBS exclusive "part-track controls" for just-in-time processing. The system will handle parts in material thickness from 16 gauge to 1" in any random order, part to part, and adjust the cure automatically to each part without changing line speed.

The conveyor is 458, 4" I-beam with load bars that provide an 8" hang center with a maximum weight capacity of 1,600 lb/part. The 4" beam allows the shop to run the heavy parts and the centers for hanging provide flexibility for different types of loads.

Being a job shop with more than 100,000 different parts in its laser database with a focus of getting more value-added work from its customers was a big factor in going to powder and selecting the features that the system should have. The company needed fast color change capability along with the flexible cure characteristics for the various parts masses. It also had to have a way to reliably remove laser scale from the part edges. The system had to be flexible for very large parts but efficient for smaller parts. It also had to be operator friendly and environmentally compliant.

All of the needed features are built in to the system. The complete system is monitored and controlled by central PLC controller that also talks to the Nordson controls.

With the new powder coating system in place, the company has restructured its capabilities from start to finish, turning a long-time grain elevator manufacturer into a high-tech fabrication and coating job shop. Based on the work it has done so far, it is likely that Grain Belt's business will continue to elevate.

For more information about the suppliers mentioned in this article, they can be contacted as follows: Grain Belt Co. Inc., 800-255-2742, www.grainbeltsupply.com; Spray Booth Systems, 800-793-7727, www.sprayboothsystems.com; Nordson Corp., 440-985-4000, www.nordson.com; Chemetall-Oakite, 908-508-2244, www.oakite.com; R3 Technologies Inc., 817-313-6439, www.r3web. com; and Protherm, 320-834-3370, www.pro-therm.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!