Sophisticated Sanding

Advances in abrasive technology are helping finishing professionals save time, energy and money while achieving a precise finish.

It is fact of life for finishing professionals in woodworking and many other industries: No matter what they do, they can't get away from sanding. And sanding. And sanding. And then sanding some more. For this reason, the sanding materials are just as important as the type of coating used. Just as different sawblades are used to make the correct cut depending on the type of wood/substrate and whether it is being crosscut or ripped, abrasives are a precision tool used to bring about the exact finish needed.

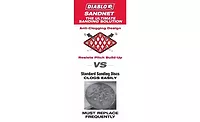

However, inherent with the use of abrasives are problems such as clogging and wear. These problems can actually stem from the way sandpaper is manufactured. Adhesives, which are used to hold the abrasive grains in place, heat up during use and cause dust particles to become part of the sanding grit. Haphazard placement of the grains can cause different sheets of sandpaper of the same grit and type of abrasive used on the same material to mysteriously wear down at different speeds. Another problem with this haphazard placement is the tendency for coatings to gum up the sandpaper. Previously, the only solution was to replace the sandpaper and continue sanding.

Recent advances in abrasive technology have been developed to overcome these challenges. Through a precise combination of manufacturing materials and electrostatic placement of the abrasive grains, the new abrasives can minimize clogging and reduce the amount of elbow grease needed.

In addition to his position as Russell Plywood's finishing manager, Karmonick is also a sanding expert who offers instruction on the subjects to the company's clients.

The new technology uses a heat-resistant adhesive that prevents the grit from sinking into the adhesive during friction. This flexible adhesive also allows the grit to sweep back and forth like a broom, which allows an aggressive cut. A thin, clear coat of polymer, applied to the grit, creates a thin barrier that further prevents clogging. The precise combination of backing, grit, adhesives and coating provides a surface that is resistant to clogging.

Electrostatic placement of the abrasive grains is also essential in ensuring that the cutting edges are all brought to bear. In the normal sandpaper manufacturing process, adhesive is first applied to the paper, and then abrasive particles are applied. The abrasive grains have sharp edges, but how those edges will land - upward, sideways or down - is left entirely to chance. In some cases, they even get submerged in the glue and disappear altogether.

As a result, one never knows how sharp a cutting edge the sandpaper will have. The haphazard placement also causes good cutting edges to break or wear down faster. Once those cutting edges are gone, that's the end of that sanding pad, disc or belt.

The random grit placement also contributes to a buildup of dust or material in the sandpaper. When abrasive particles are lying sideways, dust particles from the material being sanded tend to layer onto the abrasive particles, rendering the sandpaper ineffective. Additionally, as a surface is sanded, friction causes the glue holding the grit to heat, which attracts and absorbs dust particles, while also pushing the grit into the adhesive and sealing it in. In either case, once enough buildup has occurred, the sandpaper is headed for the trash can.

Electrostatic placement, which causes the grains to always land with the sharp side upward, allows every grain to have an abrasive edge. Electrostatic coating also allows the grains to be spaced evenly. Normal sandpaper has the grains grouped closer, which enhances clogging. With the grains spaced farther apart, clogging is reduced, and superior cutting power is achieved.

This all changed, however, when Russell Plywood discovered abrasives incorporating the clog-resistant design and electrostatic coating. "This type of abrasive is great in my end of the business, the chemical coating end," says Karmonick. "When we find a specialty product like this, something that works as well as it does, and serves us in as many aspects as this does, we jump on it. Now we can go to our customers and say, ‘Take a look at this piece of technology. It looks like the normal sanding pad that you would buy. It is not.' Our customers try it, then come back and say, ‘This is what I want. This is what I'm looking for.'"

These abrasives have been reported from users to last four times longer than regular sanding pads, thanks in a large part to the clog-resistant design, and, according to Karmonick, "The finished job looks phenomenal."

With normal abrasives, the grit can come off the paper rather easily. It's simply annoying when that grit accumulates on a finishing professional's hands or clothing, but it's a nightmare if it comes off and sands into the finish. The new abrasive technologies, however, retain the grit and eliminate yet another costly and time-consuming sanding problem.

With the new technologies, professionals in woodworking and other industries can turn simple sanding into precise finishing.

It is fact of life for finishing professionals in woodworking and many other industries: No matter what they do, they can't get away from sanding. And sanding. And sanding. And then sanding some more. For this reason, the sanding materials are just as important as the type of coating used. Just as different sawblades are used to make the correct cut depending on the type of wood/substrate and whether it is being crosscut or ripped, abrasives are a precision tool used to bring about the exact finish needed.

However, inherent with the use of abrasives are problems such as clogging and wear. These problems can actually stem from the way sandpaper is manufactured. Adhesives, which are used to hold the abrasive grains in place, heat up during use and cause dust particles to become part of the sanding grit. Haphazard placement of the grains can cause different sheets of sandpaper of the same grit and type of abrasive used on the same material to mysteriously wear down at different speeds. Another problem with this haphazard placement is the tendency for coatings to gum up the sandpaper. Previously, the only solution was to replace the sandpaper and continue sanding.

Recent advances in abrasive technology have been developed to overcome these challenges. Through a precise combination of manufacturing materials and electrostatic placement of the abrasive grains, the new abrasives can minimize clogging and reduce the amount of elbow grease needed.

The new abrasives have been reported from users to last four times longer than

regular sanding pads, thanks in a large part to their clog-resistant design.

Optimized Cutting

The difference between the new abrasives and conventional products can be seen in the finished wood. "You can actually hold up the finished sanding job to the light and look at it after you sand with one of these new abrasives," says Bob Karmonick, finishing manager for Russell Plywood, Inc. of Reading, PA. Russell Plywood is a wholesaler of cabinet interior-grade plywood, along with coatings and other complementary products, to cabinetry shops large and small.In addition to his position as Russell Plywood's finishing manager, Karmonick is also a sanding expert who offers instruction on the subjects to the company's clients.

The new technology uses a heat-resistant adhesive that prevents the grit from sinking into the adhesive during friction. This flexible adhesive also allows the grit to sweep back and forth like a broom, which allows an aggressive cut. A thin, clear coat of polymer, applied to the grit, creates a thin barrier that further prevents clogging. The precise combination of backing, grit, adhesives and coating provides a surface that is resistant to clogging.

Electrostatic placement of the abrasive grains is also essential in ensuring that the cutting edges are all brought to bear. In the normal sandpaper manufacturing process, adhesive is first applied to the paper, and then abrasive particles are applied. The abrasive grains have sharp edges, but how those edges will land - upward, sideways or down - is left entirely to chance. In some cases, they even get submerged in the glue and disappear altogether.

As a result, one never knows how sharp a cutting edge the sandpaper will have. The haphazard placement also causes good cutting edges to break or wear down faster. Once those cutting edges are gone, that's the end of that sanding pad, disc or belt.

The random grit placement also contributes to a buildup of dust or material in the sandpaper. When abrasive particles are lying sideways, dust particles from the material being sanded tend to layer onto the abrasive particles, rendering the sandpaper ineffective. Additionally, as a surface is sanded, friction causes the glue holding the grit to heat, which attracts and absorbs dust particles, while also pushing the grit into the adhesive and sealing it in. In either case, once enough buildup has occurred, the sandpaper is headed for the trash can.

Electrostatic placement, which causes the grains to always land with the sharp side upward, allows every grain to have an abrasive edge. Electrostatic coating also allows the grains to be spaced evenly. Normal sandpaper has the grains grouped closer, which enhances clogging. With the grains spaced farther apart, clogging is reduced, and superior cutting power is achieved.

Precise Finishing

Quality has always been paramount for Russell Plywood. For this reason, the company is very specific about the products it sells along with its plywood and coatings. For many years, sandpaper wasn't part of its offering. "We get a lot of people in our business that rely on us specifically for almost everything," Karmonick says. "But, when they came to us saying, ‘Do you have something that sands sealer, primer or other coatings better?' I had to say, ‘No, we don't,' because everybody else out there in our marketplace sells sandpaper."This all changed, however, when Russell Plywood discovered abrasives incorporating the clog-resistant design and electrostatic coating. "This type of abrasive is great in my end of the business, the chemical coating end," says Karmonick. "When we find a specialty product like this, something that works as well as it does, and serves us in as many aspects as this does, we jump on it. Now we can go to our customers and say, ‘Take a look at this piece of technology. It looks like the normal sanding pad that you would buy. It is not.' Our customers try it, then come back and say, ‘This is what I want. This is what I'm looking for.'"

These abrasives have been reported from users to last four times longer than regular sanding pads, thanks in a large part to the clog-resistant design, and, according to Karmonick, "The finished job looks phenomenal."

With normal abrasives, the grit can come off the paper rather easily. It's simply annoying when that grit accumulates on a finishing professional's hands or clothing, but it's a nightmare if it comes off and sands into the finish. The new abrasive technologies, however, retain the grit and eliminate yet another costly and time-consuming sanding problem.

With the new technologies, professionals in woodworking and other industries can turn simple sanding into precise finishing.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!