Periodic Pulse Reverse Systems for Decorative Copper Plating

Acid copper, which has traditionally been used for decorative copper plating, carries the drawback of poor throwing power. As a result, excessive plating times are required to achieve minimal copper thicknesses in low-current-density areas, and too much copper metal is applied in the high-current areas, leading to wasted metal and added costs. One possible solution is the use of pulse plating. Pulse plating provides exceptional deposit distribution, which reduces metal usage, and it lowers the metal concentration in the electrolyte, which reduces the amount of drag-out losses and sludge produced in waste treatment.

Direct current acid copper plating has long been used in decorative copper plating applications such as automotive wheels and plumbing fixtures because of its high leveling and bright covering power. However, as with most acidic-based electrolytes, acid copper carries the drawback of poor throwing power. As a result, excessive plating times are required to achieve minimal copper thicknesses in low-current-density areas, and too much copper metal is applied in the high-current areas, leading to wasted metal and added costs. Additionally, complex shapes can be difficult - and sometimes even impossible - to plate. Issues such as high metal prices, high charges to dispose of metal-containing waste, and the need to increase productivity on existing plating lines are forcing many decorative plating companies to look for an alternative.

One possible solution is the use of a periodic pulse reverse (PPR) system, also known as pulse plating.1 Pulse plating provides exceptional deposit distribution, which reduces metal usage, and it lowers the metal concentration in the electrolyte, which reduces the amount of drag-out losses and sludge produced in waste treatment. It also produces excellent low-current-density brightness, thereby making it easier to plate complex shapes. The brightness and leveling are similar to traditional decorative acid coppers, which makes it an easy replacement for current acid copper systems.

The high cost to dispose of metal-containing wastes is also driving companies away from acid copper plating. Most platers pay to put the metal into their plating bath and then pay to have it treated from the rinse tanks, and most of this electroplating waste ends up in landfill. The most economic method to minimize this impact is to reduce the amount of sludge generated at the source.

Further, as all companies strive to increase productivity on existing lines, decorative platers are finding that direct current acid copper plating operations limit their ability to achieve this goal because of the amount of time required to reach minimum copper thicknesses. Plating times of 30 to 60 minutes are not uncommon, and this can limit production capacity.

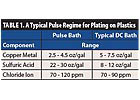

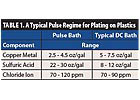

The pulsed reverse current produces desorption of the special additives above a threshold current density. This desorption increases the “resistance” in high current density (HCD) areas and thereby increases the “throwing power” of the electrolyte. A typical pulse regime for plating on plastics is shown in Table 1.

Compared to traditional acid copper plating, PPR systems use lower concentrations of copper metal and therefore reduce the amount of sludge generated in the process. Because of the improved throw of the plating into low current density (LCD) areas, PPR systems require less time to reach minimum copper thicknesses. (See Figure 2).

Compared to traditional acid copper plating, PPR systems use lower concentrations of copper metal and therefore reduce the amount of sludge generated in the process. Because of the improved throw of the plating into low current density (LCD) areas, PPR systems require less time to reach minimum copper thicknesses. (See Figure 2).

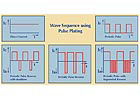

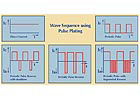

To take advantage of higher current densities (x2 on reverse cycle), the use of both air agitation and inductors might be an advantage. However, air agitation alone might be sufficient in many applications. The pulse regime/waveform is controlled by PC (see Figure 3).

The PPR system has also been used for more than a year in full production at a job shop in the Midwest U.S. A significant number of processed parts are for high-end applications and therefore require a very high-quality finish. The company has seen a savings of 20% in copper metal and a 30% reduction in plating time while achieving excellent deposit distribution. It has been able to plate complicated parts more reliably due to the superior bright throwing power at extreme low current densities. Additionally, the company has reaped the benefit of easier bath maintenance.

Copper plating using periodically reversed current provides a solution to these issues. Companies that have already made the change to the periodic reverse process report a material savings of around 20%, along with a reduction in plating times and the ability to more successfully plate complex shapes.

Two investments are required to implement this technology, including the installation of a low-metal, high-acid electrolyte and the purchase of a rectifier capable of producing the desired periodic reversed waveform. However, platers that use PPR have consistently remarked on both the ease of use and industrial “robustness” of the process. The examples given in this article demonstrate that pulse reverse plating can reduce operating costs by minimizing copper metal waste, reducing effluent costs and optimizing plating times.

For more information about pulse reverse plating, visit www.macdermid.com.

References

1. Gardner, A. Herdman, R. Kaiser, C. Griffin, S., ”Saving Costs by Copper Plating with Periodic Pulse Reverse Systems,” Coatings for Plastics Seminar, Chicago, IL, June 2007.

2. Holland, P., Mining & Quarry World, December 2006.

Copper-plated automotive parts.

Direct current acid copper plating has long been used in decorative copper plating applications such as automotive wheels and plumbing fixtures because of its high leveling and bright covering power. However, as with most acidic-based electrolytes, acid copper carries the drawback of poor throwing power. As a result, excessive plating times are required to achieve minimal copper thicknesses in low-current-density areas, and too much copper metal is applied in the high-current areas, leading to wasted metal and added costs. Additionally, complex shapes can be difficult - and sometimes even impossible - to plate. Issues such as high metal prices, high charges to dispose of metal-containing waste, and the need to increase productivity on existing plating lines are forcing many decorative plating companies to look for an alternative.

One possible solution is the use of a periodic pulse reverse (PPR) system, also known as pulse plating.1 Pulse plating provides exceptional deposit distribution, which reduces metal usage, and it lowers the metal concentration in the electrolyte, which reduces the amount of drag-out losses and sludge produced in waste treatment. It also produces excellent low-current-density brightness, thereby making it easier to plate complex shapes. The brightness and leveling are similar to traditional decorative acid coppers, which makes it an easy replacement for current acid copper systems.

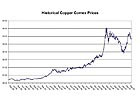

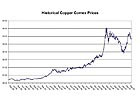

Figure 1. Copper metal pricing, May 2002-May 2007.

Acid Copper Plating Challenges

One of the primary challenges of acid copper plating is the high cost of metal. As shown in Figure 1, the price of copper metal increased from $0.73 per pound in May of 2002 to $3.51/lb in May of 2007. These price increases have been influenced by a variety of factors. For example, China’s continuing economic growth has indicated that reserves will diminish, and demand for mined copper will again resume. The North American residential housing market was forecast to pick up during the second quarter of 2007, which would increase in the demand for copper. The fear of rockslides in January at the Coldelco mine in Chuquicamata (the producer of 21% of the world’s Cu ore) caused a 4.5% increase in prices. Additionally, copper metal pricing is no longer a simple correlation of supply and demand due to “investments by commodity index funds playing an increasingly important role in determining copper price.”2 New ventures, such as sea-floor mining, are not likely to have an impact on copper price many years. Taking these factors into account, market analysts forecast that the price for copper will remain high throughout 2007.The high cost to dispose of metal-containing wastes is also driving companies away from acid copper plating. Most platers pay to put the metal into their plating bath and then pay to have it treated from the rinse tanks, and most of this electroplating waste ends up in landfill. The most economic method to minimize this impact is to reduce the amount of sludge generated at the source.

Further, as all companies strive to increase productivity on existing lines, decorative platers are finding that direct current acid copper plating operations limit their ability to achieve this goal because of the amount of time required to reach minimum copper thicknesses. Plating times of 30 to 60 minutes are not uncommon, and this can limit production capacity.

Table 1.

PPR Advantages

In both operation and application, very few differences exist between pulse reverse plating and direct current acid copper systems. The primary visible difference is in the rectification. With PPR systems, rectifiers are software-controlled, and all work practices and batch files can be pre-programmed. Additionally, like traditional acid copper systems, PPR systems use a brightener, carrier and wetter additive system, and the additive package can be fully analyzed. Traditional acid copper plating also uses two or three maintenance additives.The pulsed reverse current produces desorption of the special additives above a threshold current density. This desorption increases the “resistance” in high current density (HCD) areas and thereby increases the “throwing power” of the electrolyte. A typical pulse regime for plating on plastics is shown in Table 1.

Figure 2. Productivity comparison on existing plating lines.

Figure 3. Illustrations of the pulse regime/waveform.

Equipment Requirements

PPR systems require the use of rectifiers that supply square wave forms, as well as special cabling to avoid inductance. (Either coaxial or twisted welding cable is recommended.) A tank with weir is also required because pulse plating consumes additives at a higher rate than DC acid plating.To take advantage of higher current densities (x2 on reverse cycle), the use of both air agitation and inductors might be an advantage. However, air agitation alone might be sufficient in many applications. The pulse regime/waveform is controlled by PC (see Figure 3).

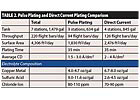

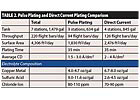

Table 2.

Case Studies

One of the largest automotive plating-on-plastics job shops in Europe has been using pulse reverse copper technology for more than a year on a full production line. The company has achieved a net savings of 20% in copper anode and salt materials while producing deposits comparable in leveling and bright throwing power to conventional systems. Minimum thicknesses achieved with the PPR system are higher than with the direct current system, even considering the lower average current densities used. However, parts plated at higher current densities tend to give the most improvement in distribution. Using the PPR system, the company has also been able to more easily plate precise tolerance parts. Table 2 compares the PPR and DC systems at this facility.The PPR system has also been used for more than a year in full production at a job shop in the Midwest U.S. A significant number of processed parts are for high-end applications and therefore require a very high-quality finish. The company has seen a savings of 20% in copper metal and a 30% reduction in plating time while achieving excellent deposit distribution. It has been able to plate complicated parts more reliably due to the superior bright throwing power at extreme low current densities. Additionally, the company has reaped the benefit of easier bath maintenance.

Optimized Decorative Plating

If current metal prices remain high, then platers of copper metal will be faced with the choice of either accepting current (or increased) expenditures, or reviewing new technologies that can reduce copper metal use. It also is unlikely that pressures on the disposal of electroplating waste will diminish, leaving platers with the dilemma of how best to lessen the impact by reducing the amount of sludge generated.Copper plating using periodically reversed current provides a solution to these issues. Companies that have already made the change to the periodic reverse process report a material savings of around 20%, along with a reduction in plating times and the ability to more successfully plate complex shapes.

Two investments are required to implement this technology, including the installation of a low-metal, high-acid electrolyte and the purchase of a rectifier capable of producing the desired periodic reversed waveform. However, platers that use PPR have consistently remarked on both the ease of use and industrial “robustness” of the process. The examples given in this article demonstrate that pulse reverse plating can reduce operating costs by minimizing copper metal waste, reducing effluent costs and optimizing plating times.

For more information about pulse reverse plating, visit www.macdermid.com.

Author's Acknowledgements

The author wishes to thank Christian Kaiser, Rod Herdman, Skip Griffin and Alan Gardner, all of MacDermid, Inc., who wrote the original presentation on which this article is based.1References

1. Gardner, A. Herdman, R. Kaiser, C. Griffin, S., ”Saving Costs by Copper Plating with Periodic Pulse Reverse Systems,” Coatings for Plastics Seminar, Chicago, IL, June 2007.

2. Holland, P., Mining & Quarry World, December 2006.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!