High-Performance Coatings for Plastics

Fluorine-based coatings are used extensively for surface protection due to their water and oil repellency, weatherability, chemical resistance, stain repellency and durability. Silicone-based chemistries, which offer fast, low-temperature curing, have been investigated for numerous applications, especially on plastic substrates, for their potential to increase productivity and energy savings. Recently, a silicone-cure fluoropolymer coating has been developed that combines the beneficial attributes of both technologies.

Fluorine-based coatings are used extensively for surface protection due to their water and oil repellency, weatherability, chemical resistance, stain repellency and durability. Silicone-based chemistries, which offer fast, low-temperature curing, have been investigated for numerous applications, especially on plastic substrates, for their potential to increase productivity and energy savings.

Recently, a silicone-cure fluoropolymer coating has been developed that combines the beneficial attributes of both technologies. With its excellent physical properties and low-temperature-cure capabilities, the new coating offers new opportunities in a variety of applications.

Monomers such as tetrafluoroethylene and chlorotrifluoroethylene can be copolymerized with a variety of different vinyl monomers to yield polymeric materials that are amorphous in structure and have excellent solubility in common organic solvents. Reactive functionality can also be introduced into these copolymers by adding suitably functionalized monomers during the polymerization process. Polymers of this type can be processed at room temperature and can be readily fabricated into coatings and films on a variety of substrates. Using TFE as the monomer enables some of the inherent characteristics of PTFE - such as excellent weatherability and dirt resistance - to be retained in the final copolymer (TFEC), but with the added advantage of the improved ease of processing. The properties of common fluoropolymers are summarized in Table 1.

The accelerating interest in reducing energy consumption and the environmental load has increased the demand for fast and low-temperature-cure processability and adhesion to various substrates without requiring surface treatments or primers. Researchers began investigating whether a silicone-curable fluoro resin technology could impart these properties to the TFEC-based coating.

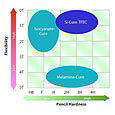

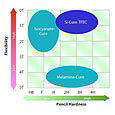

In terms of the cured film properties of the silicone-based TFEC coating, Figure 2 summarizes the relationship between the flexibility and hardness of the TFEC-based coatings using the different cure systems on aluminum plates. Surprisingly, the silicone-based TFEC coating displayed excellent flexibility as demonstrated by the T-bend test (0-1T), in spite of the high surface hardness (H-3H). The flexibility and hardness of the melamine- or isocyanate- cured films depended on the crosslinker type, crosslink density, cure temperature and cure time, but they usually gave trade-off results, such as high hardness with poor flexibility or low hardness with good flexibility. The combination of good flexibility and high hardness in the silicone-based TFEC coating can provide resistance to mechanical damage after coating and formability of coated substrates.

In terms of the cured film properties of the silicone-based TFEC coating, Figure 2 summarizes the relationship between the flexibility and hardness of the TFEC-based coatings using the different cure systems on aluminum plates. Surprisingly, the silicone-based TFEC coating displayed excellent flexibility as demonstrated by the T-bend test (0-1T), in spite of the high surface hardness (H-3H). The flexibility and hardness of the melamine- or isocyanate- cured films depended on the crosslinker type, crosslink density, cure temperature and cure time, but they usually gave trade-off results, such as high hardness with poor flexibility or low hardness with good flexibility. The combination of good flexibility and high hardness in the silicone-based TFEC coating can provide resistance to mechanical damage after coating and formability of coated substrates.

Table 2 summarizes the adhesion properties of the silicone-based TFEC coating on a variety of substrates compared with conventional fluoropolymer coatings. The PVDF coating could not be applied to plastic substrates such as PET and acrylic because the required high processing temperatures would damage these materials. The silicone-based TFEC coating showed good adhesion to aluminum, stainless steel, PET and acrylic substrates initially and even after hot water immersion, while the isocyanate- and melamine-cure TFEC systems and PVDF coatings lost adhesion after hot water immersion. It was further noted that the silicone-based TFEC coating showed good adhesion to these substrates without any primers. None of the conventional fluoro-based coatings bonded to non-treated stainless steel without a primer.

Table 2 summarizes the adhesion properties of the silicone-based TFEC coating on a variety of substrates compared with conventional fluoropolymer coatings. The PVDF coating could not be applied to plastic substrates such as PET and acrylic because the required high processing temperatures would damage these materials. The silicone-based TFEC coating showed good adhesion to aluminum, stainless steel, PET and acrylic substrates initially and even after hot water immersion, while the isocyanate- and melamine-cure TFEC systems and PVDF coatings lost adhesion after hot water immersion. It was further noted that the silicone-based TFEC coating showed good adhesion to these substrates without any primers. None of the conventional fluoro-based coatings bonded to non-treated stainless steel without a primer.

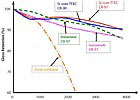

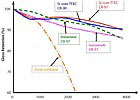

Weatherability tests showed that silicone-based TFEC coatings pigmented with titanium dioxide (TiO2) maintained 90% gloss retention after 4,000 hours using the Weather-O-Meter accelerated test procedure (see Figure 3). Unexpectedly, this long-term weatherability was better than current isocyanate- and melamine-cure systems. The incorporation of silicone-cure chemistry into the TFEC-based coating could improve weatherability due to the stability of the silicone crosslinking system.

Weatherability tests showed that silicone-based TFEC coatings pigmented with titanium dioxide (TiO2) maintained 90% gloss retention after 4,000 hours using the Weather-O-Meter accelerated test procedure (see Figure 3). Unexpectedly, this long-term weatherability was better than current isocyanate- and melamine-cure systems. The incorporation of silicone-cure chemistry into the TFEC-based coating could improve weatherability due to the stability of the silicone crosslinking system.

Author’s Acknowledgment: The following individuals contributed to this article: Masayuki Hayashi, Dow Corning Toray Ltd., Japan; Dr. Peter Hupfield, Dow Corning Ltd., United Kingdom; along with Dr. Tetsuya Masutani, Dr. Tetsuo Shimizu, Masahiko Maeda and Katsuhiko Imoto, Daikin Industries Ltd., Japan.

Editor’s note: This article is based on the paper, “New Chemistry Improves Surface Performance,” which was named the “Best Paper” at the 10th Annual International Coatings for Plastics Symposium™, co-hosted by Paint & Coatings Industry and Finishing Today in June 2007.

For more information, visit www.dowcorning.com.

Fluorine-based coatings are used extensively for surface protection due to their water and oil repellency, weatherability, chemical resistance, stain repellency and durability. Silicone-based chemistries, which offer fast, low-temperature curing, have been investigated for numerous applications, especially on plastic substrates, for their potential to increase productivity and energy savings.

Recently, a silicone-cure fluoropolymer coating has been developed that combines the beneficial attributes of both technologies. With its excellent physical properties and low-temperature-cure capabilities, the new coating offers new opportunities in a variety of applications.

Table 1.

Improving Fluoropolymers

A wide range of fluoropolymer coatings exist today that provide substantial performance benefits, but many of these coatings are limited in their use due to the processing conditions required for film formation on a substrate. One of the most common coatings is polytetrafluoroethylene (PTFE), which is used as a low-maintenance coating for cookware and bakeware. PTFE provides excellent stain resistance and durability but requires high-temperature processing when applied, thereby limiting its application to temperature-resistant substrates. Vinylidene fluoride (PVDF) and other common fluoropolymers, such as copolymers of tetrafluoroethylene and perfluoroalkyl vinylether (PFA) or tetrafluoroethylene and ethylene (ETFE), also require high-temperature processing. In addition, the high degree of crystallinity in these polymers makes their solubility in common organic solvents very poor and limits the options for processing and fabrication of these materials as coatings.Monomers such as tetrafluoroethylene and chlorotrifluoroethylene can be copolymerized with a variety of different vinyl monomers to yield polymeric materials that are amorphous in structure and have excellent solubility in common organic solvents. Reactive functionality can also be introduced into these copolymers by adding suitably functionalized monomers during the polymerization process. Polymers of this type can be processed at room temperature and can be readily fabricated into coatings and films on a variety of substrates. Using TFE as the monomer enables some of the inherent characteristics of PTFE - such as excellent weatherability and dirt resistance - to be retained in the final copolymer (TFEC), but with the added advantage of the improved ease of processing. The properties of common fluoropolymers are summarized in Table 1.

The accelerating interest in reducing energy consumption and the environmental load has increased the demand for fast and low-temperature-cure processability and adhesion to various substrates without requiring surface treatments or primers. Researchers began investigating whether a silicone-curable fluoro resin technology could impart these properties to the TFEC-based coating.

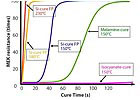

Figure 1. Comparison of the cure speed of the TFEC-based coating with different cure systems.

Testing Cure Characteristics

The cure behavior of the silicone-based TFEC coating at various cure temperatures was investigated using methyl ethyl ketone (MEK) resistance of the cured film as the response metric (see Figure 1). The silicone-based TFEC coating showed a rapidly increasing cure profile that started after a very short induction time, with complete cure achieved in 60 seconds at 302°F (150°C), while the melamine-cure system required twice the cure time to achieve good MEK resistance. The isocyanate-cure system displayed essentially no cure within the initial 120 seconds at 302°F. As the cure temperature increased from 302 to 446°F (150 to 230°C), the induction time of the silicone-based TFEC coating decreased, with a dramatic increase in the cure speed. This data demonstrates the high curing speed of the silicone-based TFEC coating system, which could provide a lower total applied cost by improving productivity and reducing energy consumption.

Figure 2. Flexibility and hardness of TFEC-based coatings.

Table 2.

Figure 3. Weatherability test of TFEC-based coatings.

Expanding Applications

Silicone-based TFEC coatings exhibit excellent weatherability, chemical resistance and anti-corrosion properties, as well as transparency, solvent solubility and compatibility with pigments and polymer additives. They provide a combination of good flexibility and high hardness, with good unprimed adhesion to many common substrates. They can also be cured quickly at low temperatures, contributing to a potential reduction in energy consumption and an increase in application flexibility. These new coatings can lower processing costs and broaden application areas for fluoropolymer coatings, especially on substrates such as plastics that are easily damaged at high fabrication temperatures.Author’s Acknowledgment: The following individuals contributed to this article: Masayuki Hayashi, Dow Corning Toray Ltd., Japan; Dr. Peter Hupfield, Dow Corning Ltd., United Kingdom; along with Dr. Tetsuya Masutani, Dr. Tetsuo Shimizu, Masahiko Maeda and Katsuhiko Imoto, Daikin Industries Ltd., Japan.

Editor’s note: This article is based on the paper, “New Chemistry Improves Surface Performance,” which was named the “Best Paper” at the 10th Annual International Coatings for Plastics Symposium™, co-hosted by Paint & Coatings Industry and Finishing Today in June 2007.

For more information, visit www.dowcorning.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!