Temperature-Compensated Viscosity Key to Coating Consistency

Traditionally, researchers monitor viscosity based on two numbers—one for viscosity and one for temperature—to create lookup tables for their process control limits, which can be time consuming. Temperature-Compensated Viscosity (TCV) determines the viscosity of a fluid at a reference temperature that is different from the actual process temperature. TCV mathematically removes the variation in viscosity caused by temperature to determine if the change in viscosity is being altered by the percent solids present, the desired control parameter for most coating operations.

For Revision Military, a Vermont-based military eyewear company, TCV has proven particularly beneficial. Revision uses TCV to help control coating thickness on their high-quality, military-grade lenses. Coating application is a critical step in the final stage of production that provides the lenses with their protective scratch- and impact-resistant properties.

Revision uses a combination of measurements, including viscosity, to improve their understanding of film thickness. For many processes, viscosity is the primary measurement and process control variable that correlates to the ultimate goal of determining the proper percent solids and consistent coating thickness. Other fluid properties are measured only for troubleshooting or supplemental data.

Unfortunately, for some formulations, direct solids measurement is limited to off-line testing rather than continuous in-line testing. It also does not provide the data Revision needs to deal with difficult fluid/geometric interactions. “We work with challenging geometries, and the shape of the lenses often interacts with the coating fluids in complex ways,” says Revision Military Process Engineer Blair Altemus.

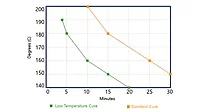

Revision utilizes VISCOpro viscometers made by Cambridge Viscosity that directly incorporate TCV. In order to implement TCV, Revision first established a viscosity/temperature profile for their coatings. Then they followed Cambridge’s simple procedures to program the coating profile into the sensors to accommodate the specific viscosity of the particular coatings used for each lens type. TCV is a true driver of the company’s manufacturing process. “We found TCV closely approximates the solid levels. It allows us a relatively large window of operation within the pot life of the material and continuous measurement capability, and reduces the amount of off-line testing and manual adjustment that might otherwise have to be done.” says Altemus.

The viscosity data has proven to be a valuable trouble-shooting tool, allowing Revision to identify issues in real-time, rather than having to troubleshoot and resolve problems downstream after the fact. TCV has also allowed the company to confirm viscosity data with other data, such as solids data. “It paints a picture of molecular weight without having to actually measure molecular weight,” says Altemus. “Combined with other techniques, TCV provides real insight into shelf stability.”

“Coating process control through TCV enables cost savings to coaters on several levels. It saves operating costs by keeping the coating machines running at their optimal rate without having to chase changes in viscosity due to temperature. Real-time automatic measurement and control saves labor, laboratory time and material scrap, while improving the uniformity and quality of the product made,” says Cambridge Viscosity President Robert Kasameyer.

TCV gives manufacturers and researchers confidence in the stability of the coating process, by allowing for greater process control. As a means to a successful outcome, TCV can be a valuable and useful viscosity control method for a wide range of coating applications.

Revision develops and delivers purpose-built protective soldier equipment for military use worldwide. The company, which began with eyewear, has expanded to face and head protection and continues to develop its capabilities for integrated, performance-enhancing soldier systems. Clients include the U.S. Department of Defense, the Canadian Department of National Defence, the Netherlands Defence Materiel Organization, the Swiss Federal Department of Defence, the German Federal Defence Force and the UK Ministry of Defence. Privately owned and ISO 9001:2008 certified, Revision’s operational headquarters is located in Essex Junction, VT, with additional offices in the Netherlands and Canada.

About Cambridge Viscosity

Cambridge Viscosity’s advanced laboratory and production viscometer systems are used by companies worldwide to optimize product and process performance. The company’s sensors and viscometer systems conform to ASTM, DIN, JIS and ISO standards, with a range of models designed to meet specific industry and application needs. Certifications include ATEX, CE, and FM. CSA certification is available upon request.

For more information, e-mail mdalelio@cambridgeviscosity.com or visit www.cambridgeviscosity.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!