Finding Chrome Formulations Puzzling?

Silver finishes remain a popular choice by stylists for almost all coatings applications. Perhaps the most requested silver finish is a mirror, liquid metal or chrome-like effect. Strong image clarity combined with high travel give products the premium look desired by consumers. In the past, a true mirror-like metallic effect could only be achieved by plating or vacuum metallization. For coating developers, the pigments that best mimic this effect are aluminum vacuum-metallized pigments (VMPs).

These pigments can be viewed as analogous to puzzle pieces. The desired mirror look is first created in a continuous film, which is then broken down into smaller, more manageable parts – like the pieces of a puzzle. The challenge for the coatings industry is to put those pieces back together in a practical coating. This article highlights the properties of VMP aluminum and provides tips on how to complete this puzzle and create the liquid metal look desired by customers.

VMPs are Different than Other Metallic Pigments

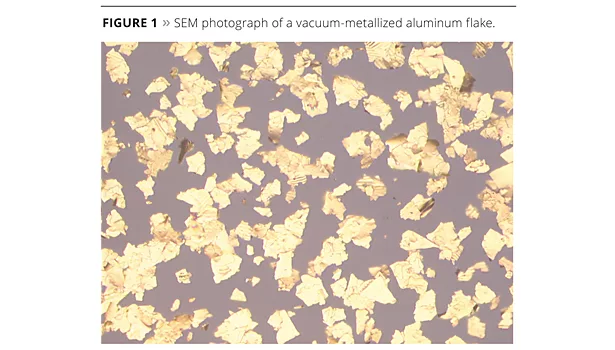

Traditional aluminum pigments are generally produced from atomized aluminum using a wet milling process.1 The mills operate such that the media cascades onto the aluminum powder, gradually flattening the malleable metal into flake form. The production process of vacuum-metallized pigments is completely different from that of a milled pigment. It begins with the vapor deposition of high-purity aluminum metal onto a flexible web substrate, which has previously been coated with a release coating. The metallized layer is then released from the host substrate and broken down into particles of a size and distribution suitable for application in surface coatings (Figure 1). The finished pigment slurries are available commercially from Sun Chemical under the trade name Benda-Lutz® SPLENDAL in the form of pigment suspensions containing 10 or 20 wt% VMP flake.

VMP Surface Properties

Conventional ball-milled aluminum flakes typically fall into two broad categories – cornflake or silver dollar. Both flake forms are lamellar but they are certainly not flat. Cornflakes have very irregular surfaces with unrefined edges. These imperfections cause light to scatter, giving reduced brilliance. Silver dollars, or lenticular flakes, have improved surface and edge characteristics but still lack the perfect structure required to produce chrome finishes. Larger particle size silver dollars can be used for improved brilliance but generally give a sparkle effect that leads to inconsistencies in shade rather than a smooth, bright finish.

On the other hand, pigments produced by vapor deposition are optically flat metallic flakes of low particle size. As shown in Table 1, they are exceptionally smooth relative to other flake types, which provides an ideal surface for the maximum specular reflection of light. This characteristic allows formulators to deliver smooth, highly reflective, brilliant finishes with outstanding flop.

Impact of VMP Thickness

In addition to a smooth surface, VMPs are orders of magnitude thinner than conventional ball-milled aluminum flakes. The average thickness of VMPs can range from 10 to 50 nm. This thin structure gives enhanced mobility within the paint formulation, allowing for improved orientation. Like all flake pigments, proper orientation is the key. Optimized orientation not only improves reflecting power, it also contributes to significant improvement in hiding power or opacity. In general, the mirror-like effect and hiding power of VMPs increases with decreasing flake thickness.3

Chrome Effect Without Surface Exposure

As discussed previously, a crucial factor in determining metallic brilliance of finished coatings is proper flake orientation or alignment. For traditional ball-milled aluminum pigments, the best method to achieve optimum alignment is by using leafing aluminum pigments. Leafing grades are developed by incorporating fatty acids in the milling process that cause the pigment to float at the surface of the paint.

This creates a highly oriented flake layer at the film surface, providing high metallic brilliance and opacity. However, the brilliance of leafing systems is offset by extremely poor surface properties, such as poor adhesion and mar resistance. Because they cover the surface of the paint film, leafing pigments are also not suitable for color-tinted systems. For these reasons, non-leafing grades predominate in the automotive industry.

Unlike traditional milling processes, the VMP manufacturing process is devoid of fatty acid lubricants, therefore, VMP flakes are completely non-leafing. In low-solids paint formulations, the VMP flakes follow the contour of the substrate, and when applied to glass-like surfaces they provide industry-leading brilliance combined with outstanding abrasion resistance and inter-coat adhesion.

Putting the Puzzle Pieces Back Together

Due to the substantial difference in physical properties relative to conventional aluminum flakes, the formulation and use of vacuum-metallized pigments is also dramatically different. To approach actual metallization, the goal is to achieve perfect alignment of a monolayer of flakes with minimal overlap. The overlapping of flakes will cause light diffusion and detract from the distinctness of image. To create the perfect effect, there are many things to consider to optimize the system and spraying conditions.

Incorporating the VMP Slurry

VMPs are sold as slurries with low pigment concentrations and are thus prone to settling. Propeller or paddle mixers (< 15 min) are generally recommended for incorporation, as they avoid excess shear. Paint shakers can also be used to produce a homogenous product (about 5 min).

Impact of Surface

VMP flakes tend to align with the contours of the coated object. To achieve proper orientation, the coating surface must be as flat and smooth as possible. Ideal surfaces for chrome effects are polished metals, high-quality films, coated papers and primed plastics. If porous or absorbent in nature, the surface will require a smooth primer coat. VMP flakes will follow any surface blemishes, which can be seen as inconsistencies in the final coating. Imperfections in the primer layer are more apparent for basecoats with low dry film thickness (DFT). For thicker basecoats, it is possible to hide defects in the primer, however, at high DFT the optical benefits of VMP are significantly reduced.

Pigment Concentration

Another critical factor when formulating with VMP is not to overload the system. Due to their ultra-thin nature, the number of flakes per unit mass of VMP is significantly higher than conventional metallic grades. Therefore, VMP-based paint uses only a small fraction of the metal of a conventional paint. The brilliance of the paint increases with increasing VMP concentration until the critical pigment concentration (CPC) is reached. In general, the CPC coincides with the formation of a uniform flake monolayer. Above the CPC, additional metal increases the thickness of the deposited film, resulting in increased scatter and reduced optical clarity.

As shown in Table 2, VMP basecoats require pigmentation levels of approximately 0.5% metal in the final paint system. It is important to note that all VMP slurries used in Table 2 contain 10% metal. As the VMP thickness decreases, the CPC of the final coating also decreases. In other words, thinner flakes like Benda-Lutz SPLENDAL 6003 require even less pigment in the final formulation. This certainly needs to be considered when calculating the overall cost of the formulated paint. Thinner VMPs are more expensive, but require far less pigment concentration.

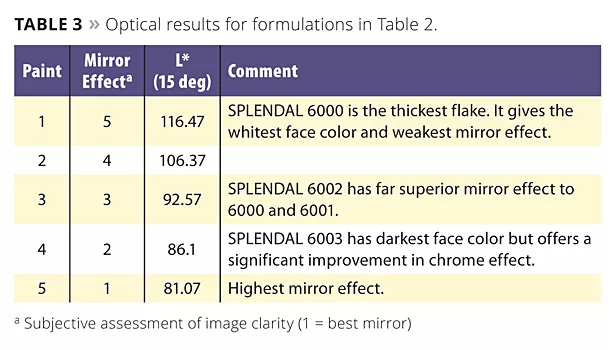

Resin Concentration

Unlike typical solvent-based aluminum systems, VMP formulations require very low solids content. Due to the low concentration of metal, it is possible to overload the system with resin. These conditions result in low film shrinkage and thus poor flake orientation. Table 3 gives some guiding formulations for the SPLENDAL range in high-chrome spray paint applications. These very low-solid formulations will have an extremely thin viscosity, which is important for proper flake orientation and maximum specular reflectance. The optical results for these formulations are given in Table 3. As shown, Benda-Lutz SPLENDAL 6003, the thinnest flake in the line, offers the highest chrome effect at the lowest slurry concentration. Increasing the metal content (Paint 5) does improve the mirror effect but also greatly impacts the overall cost of the final formulation. Therefore, the customer must evaluate the increased chrome effect versus the change in cost by using increased metal content.

VMP Solvents

Solvent selection is obviously dependent on the type of resin used. The construction materials of the object to be coated should also be considered. For metal substrates, solvent selection does not generally cause any issues. However, substrates with lower chemical resistance, like polymers or certain primed metals, can interact with the solvent, causing deleterious surface effects (etching, marring, etc.), which will impact the optical clarity of the finished coating. Evaporation rate is an important factor influencing flake orientation. Fast solvents like ethyl acetate, MIBK and acetone can evaporate too quickly, resulting in a hazy appearance. For most applications, a combination of fast- and slow-evaporating solvents is preferred.

Spraying Conditions

VMP systems are generally formulated with very low viscosities and are thus susceptible to flooding, pooling and runoff. These types of formulations are best sprayed using multiple thin coats at low film build for maximum brightness. A final DFT of 0.1 to 0.2 mils will give the best aesthetics. Sometimes higher DFTs are required for imperfect surfaces or to improve intercoat adhesion and chip resistance. In general, higher DFT requires some compromise in chrome appearance.

Clearcoat

If a topcoat is required, the basecoat should be fully cured before application. The clear topcoat should also be applied as thinly as possible. In some cases, improper selection of the clearcoat can resolubilize the basecoat resin, causing the flakes to lose proper orientation. This will essentially result in loss of chrome effect, giving a dull white appearance.

Conclusion

The unsurpassed brilliance, pronounced flop effect, gloss and opacity of vacuum metalized aluminum pigments allows coatings formulators to produce dynamic chrome effects. These unique pigments allow for unlimited styling potential in masstone and tinted paints for a variety of coatings applications. In order to utilize the full potential of these optimized flake geometries, it is important to adopt the correct formulation techniques to achieve the desired mirror effect.n

For more information, e-mail joanne.mitchell@sunchemical.com, aaron.hollman@sunchemical.com or michael.venturini@sunchemical.com.

References

1 Wissling, P. Metallic Effect Pigments, European Coatings Literature, Vincentz Network, 2006.

2 Ferguson, R.; Asia Pacific Coatings Journal, October 2005, p 36.

3 Hollman, A.; Sauseng, W.; Polymer Paint Coatings Journal, December 2012, p 26.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!