Design of Experiments Helps Develop New Specialty Chemical Product

A customer approached OMG Borchers asking if the company could provide a second source for an associative thickener used in a family of waterborne coatings. The challenge was that the thickener needed to match the properties of the incumbent thickener in three different classes of products with a different chemical composition than the incumbent. “Trying to find a mixture that delivered the required performance in all these different applications using the trial-and-error method would have been like trying to find a needle in a haystack,” said Kip Howard, National Account Manager for OM Group. Instead, Howard used the design of experiments (DOE) method to develop a mixture experiment to screen the effects of four candidate additives.

Based on the results, a second designed experiment was conducted with the two additives that performed the best in the first experiment, plus one more, and using much more detailed measurement methods. The formulation that resulted from the second DOE was virtually indistinguishable from the incumbent in all three applications. “We achieved a much better match in a fraction of the time that would have been required using traditional trial-and-error methods,” Howard said.

In this case, the customer had a line of house paints that was well received by the market and needed to develop a second source for the thickener used in the product without impacting its performance. The three key applications in which the thickener had to perform included a water-based latex primer, latex semigloss and latex gloss. The paint manufacturer wanted to use the same thickener in each of these products. The thickener needed to match the incumbent throughout the application spectrum. Low shear rate involves the thickness of the paint after it has been applied to the wall, particularly its ability to avoid running. Medium shear rate refers to the thickness of the paint during pouring and mixing. High shear rate, on the other hand, is its thickness during brushing, rolling and spraying and is particularly important in resisting splattering. The customer insisted that the new product be able to be used interchangeably with the incumbent in any application, with no discernable differences to the product or its application or performance.

“The traditional method of developing a new product for this application would involve using our best judgment about the influence of various additives to concoct a series of mixtures,” Howard said. “The chance of getting the performance in every application right is close to nil, so we would essentially be faced with a long guessing game and hoping we got lucky at some point. To improve on this approach, when I came to Borchers one of my top priorities was developing a strong DOE capability. I searched the literature on mixture designs and looked for a software package that would simplify the process of performing DOE. I selected Design-Expert® from Stat-Ease because it is the only software that I am aware of that offers user-friendly mixture design rather than providing it as an afterthought like other software,” he added. Mixture design is a type of DOE that takes advantage of the fact that the proportions of the ingredients of a mixture must add up to 100% to reduce the number of experimental runs required to evaluate the design space.

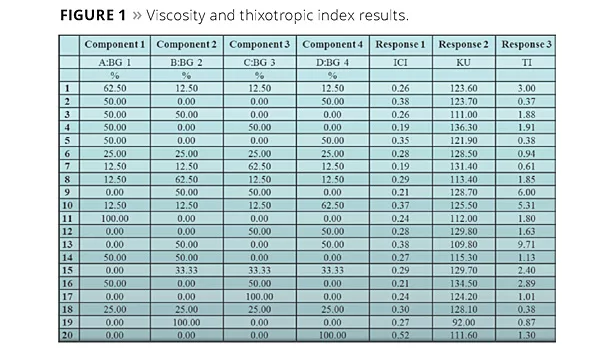

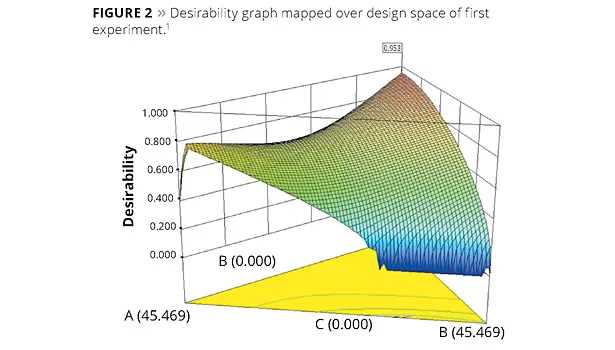

“Whenever I do a mixture design I throw common sense out the window and eliminate all of my biases,” Howard said. First Howard performed a relatively coarse screening experiment to determine which additives had the greatest impact on thickener performance in these applications. He selected four additives for evaluation, and the proportion of each additive was allowed to vary from 0% to 62.5%. The software was used to produce a quadratic mixture design with 20 runs. Each mixture was used as the rheological additive component of model formulation of the medium-shear application. They were tested for three relatively simple and quick-to-measure responses: 1) ICI viscosity as determined by a CAP 2000L viscometer; 2) Krebs Unit viscosity as determined by a KU-2 Stormer viscometer; and 3) thixotropic index as measured by a rotational viscometer (Figure 1). These results were combined into a desirability function that is calibrated to have a value of 1 when the mixture perfectly matches the incumbent’s properties (Figure 2). The experiment predicted that the desirability of the best design in the design space was 95% with a formulation consisting of 0% additive 1, 0% additive 2, 45.5% additive 3 and 54.5% additive 4. The designed experiment explores the entire design space, not just the formulations used in the 20 experimental runs.

Based on these results, a second designed experiment was developed in order to zero in more precisely on the optimal formulation. Additives one and two were eliminated and a third additive added that was expected to better match the viscosity recovery rate of the incumbent product. Five new responses were added to the design that covered all three applications and were obtained by using a research rheometer: low-shear viscosity, medium-shear viscosity, high-sheer viscosity, rebuild viscosity and rebuild time (Figure 3). The rebuild time is the amount of time required for the viscosity to build back up after shearing. The rebuild viscosity is the amount of viscosity recovered after shearing.

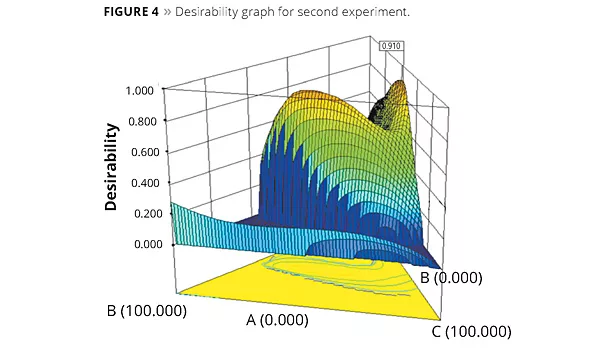

The full rheological profile performed on each formulation in this second experiment took considerably more time than the simpler approach used in the screening experiment. A desirability formula was again used to determine the optimized formulation (Figure 4). At 91%, the desirability of the optimized formulation with 52.66% additive 3 and 47.34% additive 4 was a little lower than in the screening experiment. However, the product performance was actually much closer to the incumbent’s because more rigorous measurements were used. The desirability of the optimal design as determined by the second DOE actually matched the incumbent within the margin of error of the measurement instruments.

When the formulation was prepared and tested, its performance in every application could not be discerned from the incumbent. “Mixture experiments provide a clear path to obtaining an optimum formulation with minimum expenditure of resources and time,” Howard concluded. “In addition, mixture design provides an understanding of interactions between all of the ingredients with respect to the desired properties so that future formulation development becomes less reliant on trial and error. Additional time and money is saved by characterizing limitations in order to avoid setting specification goals that are unachievable using current raw materials and processes.”

For more information, e-mail Kip.Howard@omgi.com, info@statease.com, or visit www.statease.com.

References

1 A Primer on Mixture Design: What’s In It for Formulators? Stat Ease, Inc.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!