Paint and Coating Equipment

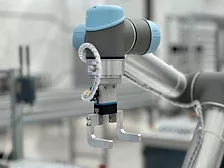

When Lab Techs Team Up with Machines

Analysis on the Testing Methods and Influencing Factors of Automatic and Manual Fineness Measurement for Paint and Coatings

Read More

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing