White Walls, Green Impact: Understanding the Connection Between Wall Color and Energy Reduction

Chemours technical experts quantify how interior wall color can impact both emissions and energy costs

Credit: alessandroguerriero, iStock / Getty Images Plus, via GettyImages

As businesses and homeowners seek new ways to lower their property’s energy costs and impact on the environment, there is one often overlooked, yet simple tactic that almost every building can benefit from: painting interior walls white. Along with providing a crisp, fresh, and clean aesthetic, white interior walls can drive a big green impact – environmentally and financially.

Evolving Energy Efficiency Tactics

The typical approach to energy efficiency has revolved around improving insulation, installing solar panels, using clean energy-powered heating and cooling systems, and replacing high-energy appliances with more efficient models. Coatings have also played a significant role in lowering a building’s energy usage and costs, usually by painting the exterior surfaces of buildings, particularly their roofs, white or another bright color. This maximizes the reflection of solar radiation and minimizes the amount of heat absorbed by these buildings. All of these remain viable and meaningful options, but excluding interior walls from the energy efficiency equation leaves savings on the table.

While tying interior white walls to energy efficiency is not a new concept, the impact has yet to be fully quantified, until now.

As a leading manufacturer of titanium dioxide (TiO2), a critical paint component that gives coatings opacity, reflectivity, and bright, white color, Chemours was uniquely positioned to quantify exactly why and how interior wall color could impact the energy efficiency of a building. We found that doing so can drastically increase a building’s energy efficiency in two primary ways:

Finding 1: Lowering Electricity Demands Leads to Cost and Energy Savings

The experiment’s findings confirmed what many have suspected: painting walls a bright white color can lead to significant energy savings for property owners. Rooms with bright white paints were able to reach 500-lux and 800-lux levels of luminosity (two levels commonly used in office buildings) with far less electricity demand thanks to the light reflective properties of the coatings on the walls.

Painting walls a bright white color required between 41% and 85% less electricity when compared to a black paint. Compared to light gray paints, painting walls white reduced additional lighting requirements by between 21% and 31%.

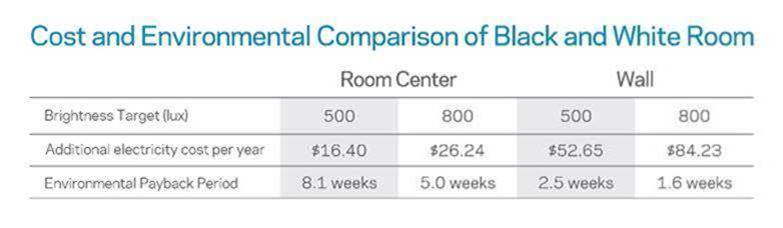

Depending on the level of preferred brightness and where in the room the brightness is measured, these additional electricity requirements can lower costs for just one room by between $16.40 and $84.21 per year. Over the service life of the paint, the additional cost of lighting a black room far exceeds the initial cost of the paint, and the cost of using greater amounts of TiO2 to brighten a room is quickly offset by the electricity savings.

In addition to the financial savings, there are also environmental benefits to painting walls white. As seen in the table below, the environmental payback period (defined as the length of time it takes for the CO2 savings from using less electricity to offset the CO2 generated when making the paint) is quite short. By painting walls white, property owners have positive CO2 impact in just a little over eight weeks for the least sensitive location (room center) at lowest illumination target, and less than two weeks for the most sensitive location (at the wall) and highest illumination level1.

Finding 2: Reducing Cooling Costs During Warmer Months

Painting interior walls white can also reduce energy costs during periods when the room is actively being cooled. Most of the light generated from a light fixture ends up as heat. This is especially true for incandescent lamps, where as little as 2% to 3% of the incoming energy is converted into visible light and the rest is released as heat.

This is problematic during warmer months when power is being used to cool the room. By decreasing the energy used to generate adequate light, less heat is generated by these lights. As a result, the amount of electricity required to cool the room also declines, leading to further reductions in energy costs and expenditures for the building. As an example, an air conditioner with an energy efficiency ratio (EER) of 10 will consume 0.33 kWh to remove the heat generated by a 1.0 kWh source such as a light. Note that this energy reduction is realized during periods of peak energy consumption (typically the hottest days of the year), and so this decreases electricity consumption at the exact time when electricity has the greatest demand.

How We Generated These Findings

In this experiment, we sought to measure the relative electrical load needed to light a room at the 500-lux level, a brightness level specified by European regulators as sufficient for work at an office, as well as the 800-lux level, a level preferred by surveyed office workers (according to a 2015 study), as it related to the brightness of the paint color used to cover each wall. A windowless room was painted white, black, and two intermediate shades of gray, and room brightness was measured at multiple locations and directions using four light levels, for both warm and cool fluorescent bulbs.

The room had a standard acoustical tile ceiling and mid-to-dark-colored carpeting in order to closely replicate a typical office building. The ceiling height was 3 meters, and most measurements were made 90 centimeters from the floor. The exceptions were measurements made 60 centimeters underneath each lighting fixture. These measurements were used to determine the luminosities of the light sources, with the intention being that all light measured at those positions comes directly from the light sources, rather than being reflected from the walls.

Luminance was measured at six locations in the room, with the meter oriented at different angles for these locations and with two different dimmable fluorescent bulbs. There were two light fixtures in the room, centrally located, and each fixture accommodated four bulbs. A diffusion panel was placed on each fixture. Within a set wall brightness and bulb type, four electrical power levels were explored at each location and orientation.

The experiment was intentionally set up to replicate the specifications found in a typical office setting as much as possible in order to make the findings applicable to the real world.

Empowering Decision Makers with Valuable Information

While personal preference will always be a major factor in color choice, it is important that architects, interior designers, and consumers be aware of all costs and opportunities of a given color option. These costs include not only monetary costs in the form of higher electricity bills, but also environmental costs from increased energy usage.

The findings of this experiment clearly show that painting interior walls a white color can significantly reduce both of these costs. With these results, property owners can make better, more informed decisions about how to paint their buildings, especially when the decision is between a light and dark color that add similar aesthetic value to a room. Also, it is important to remember selecting a paint color is not an all-or-nothing decision. Painting three walls white and incorporating a colored accent wall, or other creative solutions that maintain aesthetic value, can still lower energy costs.

As property owners continue to seek new ways to lower energy costs and consumption, painting walls a light color should be considered as a low-cost way to do so. Those wanting a “green” paint to improve the sustainability of their building may find the color they are looking for is, in fact, white.

1 For this calculation, we assume that each kilowatt hour of generated electricity results in the release of 0.71 pounds of CO2, that the white paint contains 2.5 pounds of TiO2 per gallon, and that production of each pound of TiO2 results in the release of 5.0 pounds of CO2.