High-Speed Mixers for Coatings and Inks

Credit: Charles Ross & Son Company

Credit: Charles Ross & Son Company

Credit: Charles Ross & Son Company

Credit: Charles Ross & Son Company

Credit: Charles Ross & Son Company

Credit: Charles Ross & Son Company

This article provides an overview of the different types of high-speed mixers utilized in the manufacture of coatings and inks. These machines accomplish a range of processing objectives that sometimes overlap. The recommendations discussed in this article are geared towards proper mixer selection.

Regulatory requirements in the past few decades have prompted the coatings industry to move its focus from conventional low-solid, solvent-based formulations to waterborne systems, high-solids coatings, energy-curable inks and other low-VOC technologies. This important environmentally responsible shift coincided with exciting developments of new functionalities as a response to changing customer needs. Now faced with a growing demand for specialty and high-value-added coatings, manufacturers are taking a closer look at their processing methods, particularly the mixing and milling steps. The question “What can we do better?” is asked more earnestly as coatings producers strive to improve performance and compliance while managing cost.

Infused with thermochromic, fluorescent, color-shifting, rust-inhibiting or other novel properties, modern coatings and inks may contain unique combinations of innovative raw materials, but at their heart they are still formulations that rely on good mixing. The degree of mixing and dispersion applied to a certain product invariably affects its color, gloss, conductivity, stability, adhesion properties, curing rate, weatherability and other performance characteristics. Thus, it only makes good business sense to optimize one’s mixing procedures. Even traditional products and well-established processes can benefit from a strategic reassessment of the mixing operation.

Various dispersion tools are employed in the production of coatings and inks. Some of these technologies are relatively new solutions to age-old processing issues. Mixer selection is based on a number of factors, including viscosity profile, shear requirement, order of addition and throughput.

High-Speed Dispersers

The high-speed disperser, previously called the high-speed dissolver, is a standard workhorse in the coatings industry. An economical and relatively simple piece of mixing equipment, its primary purpose is to incorporate powders into liquid and break down loose agglomerates to produce an acceptable level of dispersion prior to milling (Figure 1).

Running at tip speeds up to around 5,000 ft/min, the open disc blade of the high-speed disperser creates vigorous turbulent flow within a low-viscosity batch. It also generates a characteristic vortex into which dry ingredients can be added for quick wet-out. The disperser blade may be located on- or off-center depending on the depth of the vortex (an off-center blade produces a smaller vortex and reduces air entrapment). As the batch thickens or increases in volume, blade speed is adjusted to maintain the vortex and rate of material turnover. A few other basic guidelines are typically followed in the sizing and operation of the high-speed disperser, including:

- Normal operating viscosity range: water-like to around 50,000 centipoise (cP);

- Motor specification: 1 HP for every 10 gallons of product;

- Disperser blade diameter: approximately 1/3 of vessel diameter;

- Disperser blade location: 0.5 blade diameter off the vessel bottom – 1.5 blade diameter below the liquid surface;

- Full holding capacity of mix vessel: at least 30% greater than the size of the batch to provide sufficient freeboard above the product level.

While many manufacturers still rely on high-speed dispersers for pre-mix operations, a good number have started to integrate more powerful mixers that go beyond simple powder wet-out. The rationale behind this is: if a pre-mixer is able to disperse agglomerates as close as possible to the desired specifications – in other words, mimic the early stages of milling – it can reduce the number of passes through the mill and even allow the use of smaller grinding media for milling finer solids. This presents an opportunity for a tremendous increase in efficiency as well as a reduction in cycle time. Some of these mixer alternatives include new-generation high-shear mixers and ultra-high-shear mixers.

High-Shear Mixers

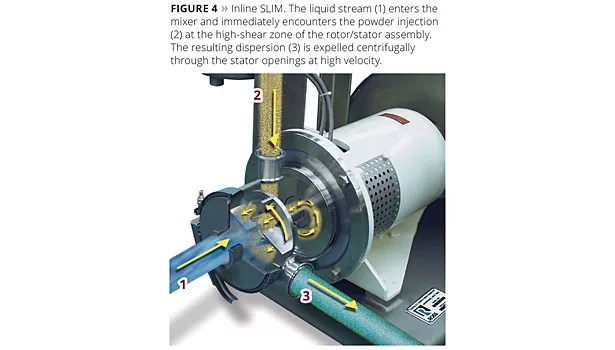

High-shear mixers are rotor/stator agitators used for more challenging solid-liquid dispersions and emulsions, which high-speed dispersers cannot adequately process. This type of mixing device typically features a four-blade rotor turning at high speeds within a stationary stator. As the blades rotate, materials are continuously drawn into the mixing head and expelled at high velocity through the openings of the stator (Figure 2). The resulting hydraulic shear promotes fast homogenization, deagglomeration and emulsification. Rotor tip speeds between 3,000 and 4,000 ft/min are typical.

Because of the restriction provided by the stator, this mixer offers higher shear but less pumping capacity than an open-disc saw-tooth disperser blade. For the same reason, its viscosity limit is lower – around 10,000 to 20,000 cP.

Another distinction is that the rotor/stator mixer is available in both batch and inline (continuous) designs. An inline high-shear mixer behaves like a centrifugal pump. It is not self-priming and requires static pressure (gravity feeding) or positive pressure (pump feeding) to introduce materials into the mix chamber. In most cases, gravity feeds product into the rotor/stator assembly as the mixer is typically positioned on the floor or on a platform below the liquid level of the recirculation tank. Standard inline models will easily move flowable products up to around 10,000 cP, depending on the formulation’s shear-thinning properties. With an auxiliary pump, moderately viscous coatings, pre-mixes and intermediates can be processed in a high-shear mixer. For large tanks (>500 gallons), the inline configuration is often more practical compared to a batch rotor/stator mixer or other top-entering high-speed agitators that require a high-horsepower motor and a relatively large blade to generate adequate circulation. An inline high-shear mixer, on the other hand, can recirculate product through a 2,500-gallon stirred tank as easily as in a 25-gallon vessel. In fact, with appropriate piping, a single inline mixer can serve multiple batch tanks of various sizes. Typical installations utilize simple valves to divert finished product downstream or switch instantly from one source vessel to another.

When large powder amounts need to be added quickly into liquid or when hard-to-disperse solids take too long to completely incorporate, a high-shear mixer with built-in sub-surface powder induction capabilities is highly worth considering. Eductor-based powder injection systems, while effective in terms of eliminating floating solids and offering more precise control over the mixing process, do suffer from frequent clogging and intensive maintenance issues. In addition, these systems require an experienced operator to perform the often difficult task of balancing the performance of three separate devices in series: the eductor, pump and mixer. High-shear mixers with an integral mechanism for powder injection are more reliable and easier to operate.

High-Shear Mixers with SLIM Technology

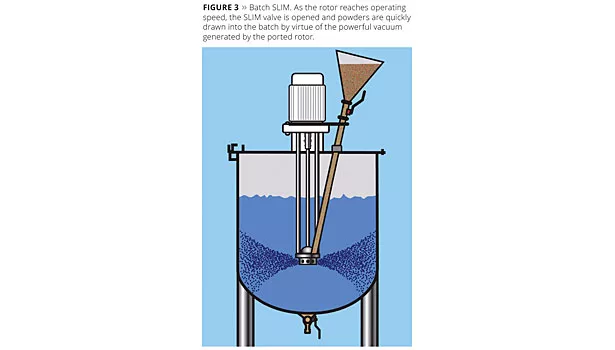

Ross high-shear mixers equipped with Solids/Liquid Injection Manifold (SLIM) technology offer a method of sub-surface powder induction that is more operator-friendly and easier to maintain than eductor-based systems. A key advantage to the SLIM design is that it does not require centrifugal pumps or eductors to create the suction for powder injection.

The SLIM features a unique rotor/stator capable of generating a powerful vacuum that draws and injects powders directly into the mixer’s high-shear zone. Because solids and liquids are combined at precisely the point where intense mixing takes place, the formation of lumps and “fish eyes” is greatly reduced, if not eliminated. In a SLIM process, powders can be delivered to the batching tank in a way that reduces “dusting” (the release of airborne particles into the mixing area), giving way to simpler clean-up and faster changeovers. This is accomplished through the use of a hose and wand attachment – a flexible hose is connected to the solids inlet port, and at the other end a stainless steel wand is dipped into bulk bags or containers to conveniently induct lightweight powders without creating a dusty environment. Less problematic solids are fed into a hopper for rapid induction aided by gravity.

SLIM technology is available in both batch and inline designs (Figures 3 and 4), which makes it simple to retrofit into most existing processes. It routinely handles solid loadings as high as 70%, depending on the application, while operating within a wide viscosity range: from water-like to up to 10,000 cP during powder injection.

Ultra-High-Shear Mixers

In addition to eductor-less powder injection systems, other rotor/stator technologies have been developed to enable coatings manufacturers to wet out powders while also accomplishing some level of grinding and deagglomeration right in the same mixing vessel.

These ultra-high-shear mixers have been shown to generate higher levels of dispersion than other batch-style mixers including saw-tooth blade-type dispersers, traditional rotor/stators and immersion mills. Mixing produces results comparable to one or two passes through a media mill. Manufacturers are, therefore, able to achieve their target particle size distribution with fewer mill passes and, in some cases, eliminate milling entirely.

There are also inline ultra-high-shear mixers capable of even more intense deagglomeration. These are available in different rotor/stator designs and run at tip speeds over 11,000 ft/min.

Multi-Shaft Mixers

Multi-shaft mixers equipped with two or more independently driven agitators working in tandem are robust systems that deliver both high-shear agitation and laminar bulk flow within a wide viscosity range: from water-like to several hundred thousand centipoise.

The simplest design is the dual-shaft mixer, which features a low-speed anchor and a high-speed saw-tooth disperser blade (Figure 5). The wings of the anchor agitator usually include adjustable scrapers for wiping the vessel bottom and sidewalls. This allows for tighter temperature control in addition to enhanced product turnover.

Another typical configuration is the triple-shaft mixer, which includes an additional rotor/stator assembly. This configuration is popular for formulations wherein the final particle size distribution is critical. As discussed earlier, using a saw-tooth blade to incorporate powders into liquid results in acceptable levels of dispersion, but applying a more shear-intensive mechanism such as rotor/stator mixing typically results in a finer and more uniform particle size distribution.

SLIM technology is an option available for Ross triple-shaft mixers with a working capacity of 4 gallons and larger. During powder injection, the liquid vehicle must be under ~10,000 cP but after all the solids are added, product viscosity may continue to climb. The latter part of the mix cycle may rely on just the anchor agitator and disperser if product flow through the rotor/stator assembly becomes too restricted.

Aside from the improved capability of multi-shaft mixers over single-shaft devices from a viscosity and heat transfer standpoint, another design advantage is that they are closed systems and can offer benefits in vacuum mixing. Processing under vacuum eliminates unwanted air voids that agitation under atmospheric conditions can produce, but just as importantly, it helps certain formulations to develop higher densities and possess better properties as a result of improved shearing and contact of the different components.

Planetary Mixers

Specialty coatings and inks that undergo very high viscosity peaks (above 1 million cP) are better prepared in planetary dispersers and double planetary mixers. These machines feature two or more blades that rotate on their respective axes while revolving around the mix vessel. In other words, all agitators continually advance into the batch and contact fresh product all the time.

For very challenging formulations, a planetary dual disperser may be utilized. This mixer consists of two disperser shafts (each having two saw-tooth blades) and two planetary stirrers.

The classic double planetary mixer (DPM), on the other hand, is ideal for melting and kneading semi-solid materials or highly viscous pastes (Figure 6). While not considered a high-speed mixer, the DPM is equipped with two identical stirrers that impart increasing levels of shear as the batch gains considerable viscosity. A common processing technique in this very robust machine is mostly high-viscosity mixing to ensure satisfactory solids dispersion (from 2 million cP up to around 6 million cP), followed by a let-down step towards the end of the cycle.

Conclusions

There are a variety of high-speed mixers available to coatings and inks manufacturers. Understanding their differences is an important step in choosing the right mixer for your process.

For more information, visit www.mixers.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!