Holidays and Pinholes: The Chink in the Armour

Figure 1

Figure 2

Figure 3

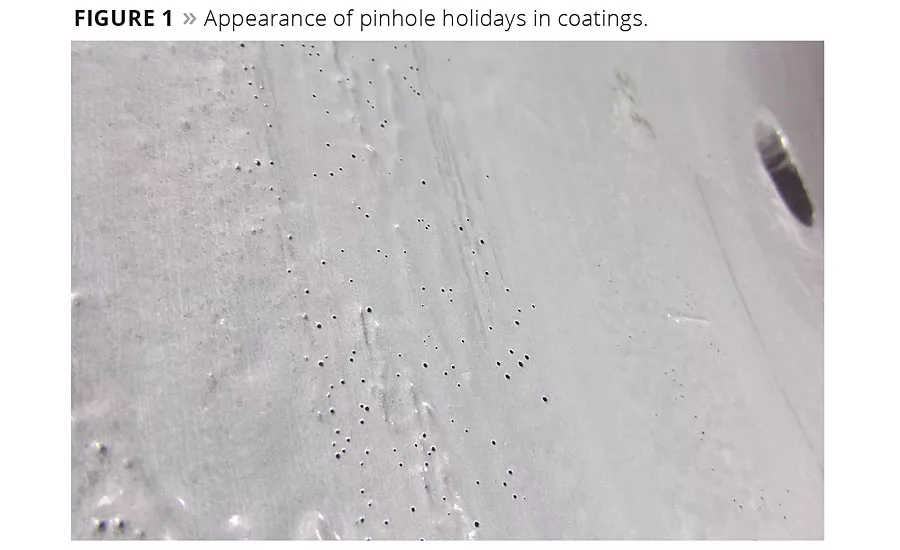

Traditionally, armor is considered only as strong as its weakest point, highlighting the significant dangers of any subsequent breach. A chink in one’s armor poses life-threatening consequences, not dissimilar to that caused by vulnerabilities within a protective coating. Any weakness can lead to the exposure of the substrate beneath, allowing access to the destructive forces of corrosion and erosion, ultimately making the coating redundant. Within the industry, these defects are referred to as holidays, an area of the substrate that has not been properly coated, presenting as a discontinuity in the coating film. This includes misses, inadequate coating thicknesses, inclusions and pinholes, all of which register as anomalies (Figure 1). Throughout this article we aim to dispel some myths surrounding holidays and pinholes, while also exploring holiday detection and the solutions used to fix these defects.

What Causes Holidays?

The occurrence of holidays can only be attributed to either applicator error or a lack of knowledge surrounding the application of coatings. This includes the knowledge of environmental conditions, which can affect and overall hinder the application. A common cause of holidays that is particularly affected by environmental conditions is the coating viscosity. Imperfect viscosity can undermine the success of the overall application. In extreme temperature conditions, the coating can become too viscous, or too fluid, and will become too difficult to apply. Subsequently, this will form sags and curtains and will undoubtedly lead to misses or skips within the coating structure.

The characteristics of the coating upon application can also increase the likelihood of holidays occurring once the coating has been cured. Primarily, insufficient or incorrect mixing of the coating’s components can create areas that won’t cure, leading to disbondment amongst other coating defects. Moreover, overmixing the coating prior to application can combine too much air with the product, creating a significant number of air bubbles.

Pinholes are predominantly formed when air bubbles rise to the surface of the coating, burst and are not resealed by the coating itself. These miniscule holes can be simply limited to the top layer of the coating, or continue directly through two coats, exposing the substrate. When brush-coating a substrate, applicators must ensure that they apply two layers. After the initial layer, the second coat must be applied perpendicular to the original, thus covering over any potential holidays that are present. If this doesn’t happen, any existing discontinuities, such as pinholes, may not be covered.

What’s more, significant areas of error stem from difficult-to-access areas and ensuring that an even coating is applied across the substrate. In perfect practice, applicators should use mirror-access techniques to remove the doubt over discontinuities in hard-to-reach locations.

Equipment and Methods of Holiday Detection

A lot of these defects cannot be visibly spotted; therefore, certain types of equipment are used to locate coating anomalies. Coatings are predominantly insulative products, protecting the conductive metal substrate. Using electricity to locate these film discontinuities, holiday detectors pass a current over the coating, trying to create a closed circuit with the substrate beneath. An anomaly can be identified by using both high- and low-voltage instruments; however each must be matched specifically with the application, dependent upon several variables. For instance, the environment’s conditions must be suitable for effectively testing the surface, especially with regards to the surface conditions. A dry and cured coating is essential for positive test results; otherwise trapped solvents or uncured areas still present within the coating can provide false readings.

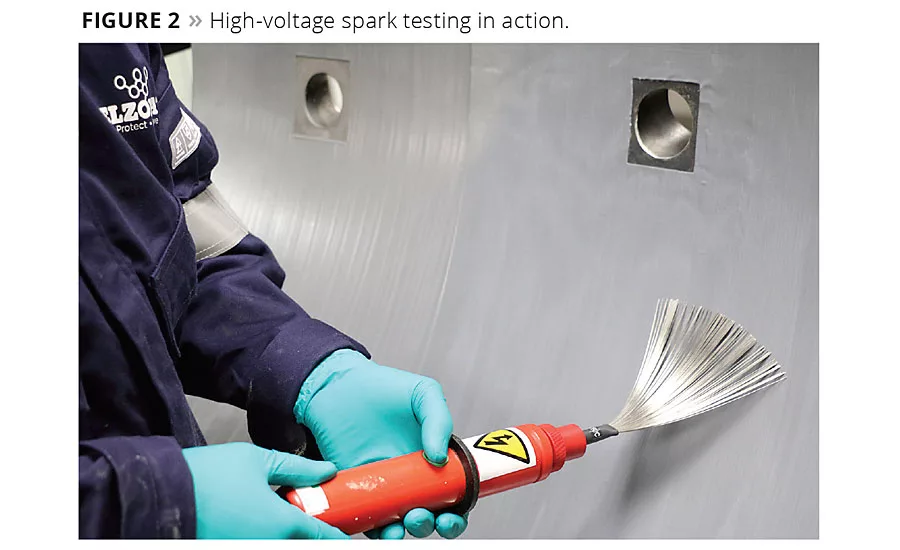

Typically, either the low-voltage wet sponge test or the high-voltage spark test is used, with each possessing distinctly different capabilities in terms of functionality. Obviously, the significant difference concerns the voltage of the two pieces of equipment; however, this does impact the type of coating each can be used for. Manufacturers’ guidelines state that the low-voltage wet sponge testers are only recommended for coatings with a maximum thickness of 500 µ (microns). For coatings that are applied at thicknesses exceeding 500 µ, high-voltage equipment should be used (assuming that the coating is compatible) (Figure 2).

Another significant difference concerns how the equipment detects the presence of holidays. The low-voltage equipment utilizes water as a pathway for the electricity to connect with the areas of exposed substrate. In contrast, the high-voltage equipment is able to bridge the gap between the tester and conductive material, simply through the air. There are also considerable safety differences in that the wet sponge system operating at a maximum of 90 V cannot harm the operator or the coating, whereas the high-voltage version operating up to 60,000 V can seriously damage both the operator and the coating being tested if not correctly operated.

Problems Surrounding Holiday Detection

One of the biggest problems surrounding holiday detection revolves around voltage settings and dielectric strength. Every coating possesses a dielectric strength, which determines the specific voltage that a coating can withstand before it begins to break down. Choosing between high- and low-voltage testers, in addition to setting the correct voltage so as not to cause further damage to the coating, is crucial when using equipment of this nature.

Ian Wade, Belzona’s NACE-certified coatings inspector, commented, “Alongside voltage, the speed of inspection can also have an impact on the coating. When using the DC high-voltage spark tester, the inspector must not move the probe too slowly across the coating in a single pass, as this can create holidays (minimum speed must be at least 0.3 m/s, 1 ft/s (NACE SP0188). Similarly, with the low-voltage holiday detector, the user will also have to make sure that full contact with the coating is continuous and not to move the probe too fast or too slowly.

“Moreover, the user will have to ensure that they do not over saturate the sponge, as this can lead to erroneous results; likewise the same problem will arise if the sponge is not saturated enough (1 part wetting agent to 128 parts water). Check the grounding of the equipment by making contact on a bare spot on the substrate with the sponge and repeat periodically to verify grounding.”

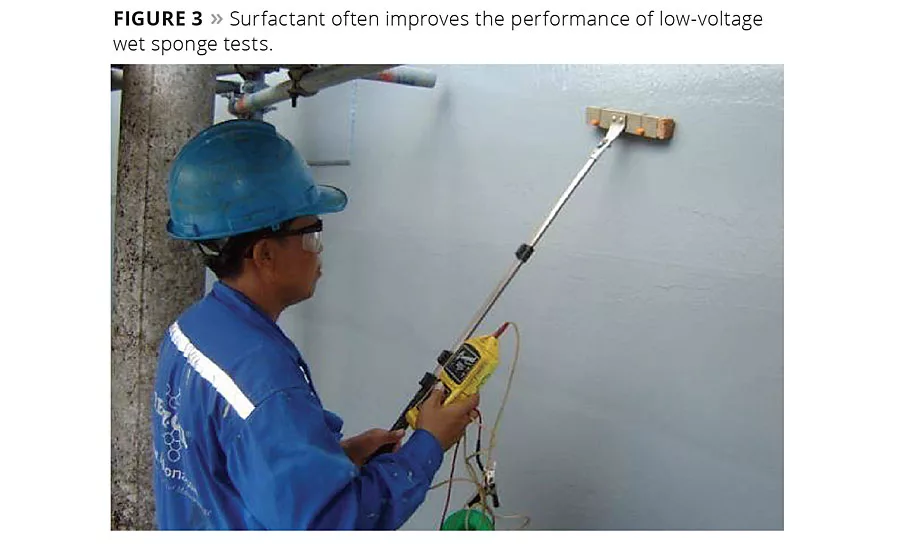

As highlighted, sometimes the pinholes are so minute that the passage of water from the low-voltage tester through to the conductive surface underneath is restricted. In these instances, applicators will use a surfactant to lower the surface tension of the water. With a reduced surface tension, the solution is able to penetrate the pinhole and effectively recognize the coating’s defect (Figure 3).

In order to provide different characteristics and additional properties to coatings, additives and fillers are added. Some of these are metallic fillers, which must be acknowledged before any testing is conducted. When confronted with metallic-filled coatings, which may be semiconductive, a low-voltage testing method technique is preferable, for example using the wet sponge technique. On the other hand, high-voltage testing equipment can be used to discern whether a non-metallic-filled coating has a holiday.

Restoring the Armor

The chances of poor application techniques can be eliminated by following specific coating guidelines and procedures. In terms of achieving the best coating possible, void of potential defects such as holidays and pinholes, it is necessary to follow NACE standard SP0188. As always, safety is paramount when using equipment of this nature, and as part of NACE guidelines there are certain measures that must be remembered. Inclusive of electrical safety checks, when conducting high-voltage tests it is necessary to carry out full assessments of the testing environment to ensure that there are no potentially explosive elements. Moreover, complete electrical grounding of the substrate is vitally important to avoid any electrical shocks.

Solutions for repairing holidays are completely dependent upon whether the coating can be renewed or not. If the lining is at the maximum coating thickness, then another coating cannot be applied on top of the existing holiday. The area around the discontinuity is initially delineated with the edges feathered in towards the defect. Once completed, the area can be frost-blasted before a replacement coating can be applied. On the other hand, if the coating is under the maximum thickness, another coating can be applied. By simply roughening the surface prior to a successive application, the holiday can be covered and successfully eliminated. After the repair is complete, another holiday test must be conducted in order to establish that the repair has been successful. Notably, the area of repair is the only place that should be tested, in order to prevent excessive stress against the coating’s integrity.

For more information, visit www.belzona.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!