How Do You Introduce a New Product Into the Coatings Industry?

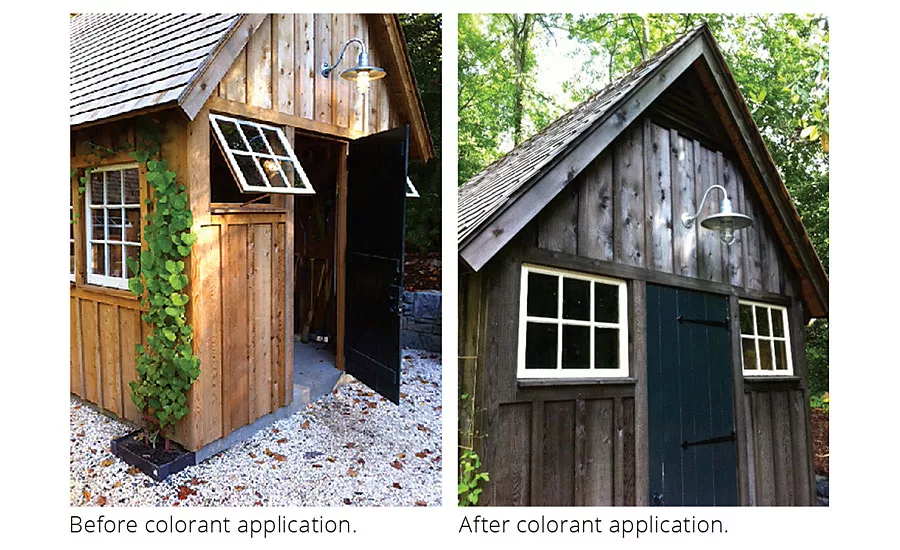

About eight years ago, I was helping a customer try to “naturally” ebonize an oak floor. In the process I discovered a wonderful brown “bark” color with a natural, aged look. Unfortunately reproducing it was impossible. From time to time in testing, the brown color would appear, but there was no determining how to recreate it. Over several years of studying old wood staining techniques and many trial and error tests using several different types of toxic and nontoxic chemical products, and natural products, not only was the wonderful brown hue reproduced, but other interesting colors became a possibility.

Interestingly, my background is neither in manufacturing or chemistry. In fact, by training I am a nurse, but for years have owned a small company that sells antique and specialty wood products, which has offered exposure to many varied and creative projects related to natural and wonderfully recyclable wood. A Masters in nursing required some extensive research, which may have set the foundation for all the research and discovery of this colorant product.

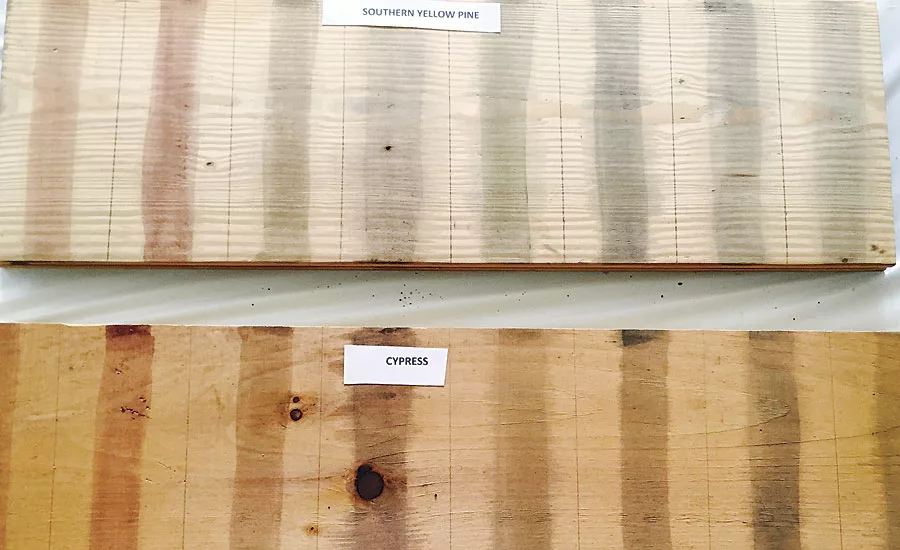

From the beginning, as an avid recycler, and most respectful of the gifts of our environment, it was important that the product be eco-friendly. This quickly eliminated strong and toxic chemicals. Making it water-based would maintain the eco-friendly status and would also be helpful with cost of manufacturing and its use by the consumer. Including products to assist with preservation seemed necessary. Other ingredients would hopefully provide stability, and even a few ingredients were added to mask other ingredients to help prevent or slow “copy cats”. Then the thought came that making the product totally powdered to be reconstituted by water would eliminate the high expense of shipping and simplify its use by the consumer. In the many hundreds of times of testing this product on different species and grades of both reclaimed and newly processed wood, it was accidentally discovered that this product is also effective in coloring concrete, fabric (color without stiffness) and even paper. As the testing continued, primary colors were explored to broaden the range of colors this product could provide. A well-known analytical company has also determined that the product could be effectively introduced with finishing products for ease of use and could also be “tweaked” to pass industry-standard testing.

It is clear with prefinished wood products surfacing regularly in the market that there is a great demand for the natural aged look. At the same time, the wood and lumber industry, as well as many other industries and agencies, are demanding greater respect for the environment. This product, although helpful in any area utilizing coloring agents, can be particularly helpful in the reclaimed industry requiring original surface appearance after cutting lumber to size or design. As I hear repeatedly from customers, there is a greater demand from the end user for safer, more environmentally friendly finishes.

The concept of actually manufacturing and marketing this product appeared to be a potential reality. Now I needed to know where to turn to achieve this undertaking. I have a product that is eco-friendly, easily manufactured by readily available ingredients, and easy and economical to produce and use. Who has the expertise to both manufacture and market such a product? An internet search brought certain concerns to the surface immediately. 1) How do I keep this product protected? 2) Where do I find the right company that would be interested and could actually benefit from the manufacturing and marketing this product? 3) Is there a way to successfully manufacture and market this product without the risk of pouring large amounts of money into it?

Since I had neither manufacturing or marketing skills on the required level, taking on this endeavor was not one to be considered. I searched, “how to introduce a new product to the coatings industry and maintain protection in the process.” There are many sites and programs that promise to get products to market for a particular fee up front, some quite pricey. (Programs such as these often focus more on the money than success). Knowing this was not the answer, I was captivated by the multiple You Tube videos and books made available by a particular group of “inventors” whose aim is to teach others to create wonderful products, protect themselves and the products, and then license them to appropriate markets. Their focus is to teach others to accomplish this achievement without spending large sums of money before the success of the product is realized. This group of inventors provided instructions on not only how to search and create new ideas, but how to protect those ideas, how to create lists of potential licensing companies and departments, how to contact the appropriate people in the specific industries, as well as how to present particular products to the target companies. This creative company of inventors also offers all types of instructions on working with prospective companies to help establish trust and a working relationship in licensing the specific products. Working with these inventors has provided the confidence and capability to move forward with this colorant as well as other products, a process that is still in progress. The hope clearly is to provide a product idea that will benefit all who are involved in its manufacturing, marketing, as well as the end user and the environment.

The idea of licensing such a product seemed to be the wisest approach to effectively move it in the right direction. In exploring this concept, it has been determined that indeed there are outside submission forms on the websites of several of the top coatings companies, but these tend to be more receptive in the marine and aerospace categories. Larger, more well-known companies also have a greater tendency to buy out smaller, well-established brands that are proven to be successful. Many other larger companies are still relying on their own R&D departments for creating new and innovative products.

Is it possible that the industry is closing the door to those who may have great contributions to be made? It seems as if the coatings industry may benefit more by exploring the ideas of those outside the industry and not just using surveys filled out by their customers. A review of many other industries shows that outside inventors have brought to market products that have benefited specific companies, certain industries and most importantly, the end user.

As far as the journey for this colorant goes, testing and exploring in an effort to perfect this product will continue. Searching for the right manufacturing and marketing home will be part of the process. Hopefully the industry will begin to realize the benefits of those creative minds out there working with special concepts and products.

For more information, email edie@edwoodslumber.com or visit www.edwoodslumber.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!