Hidden Secrets of Effect Pigments

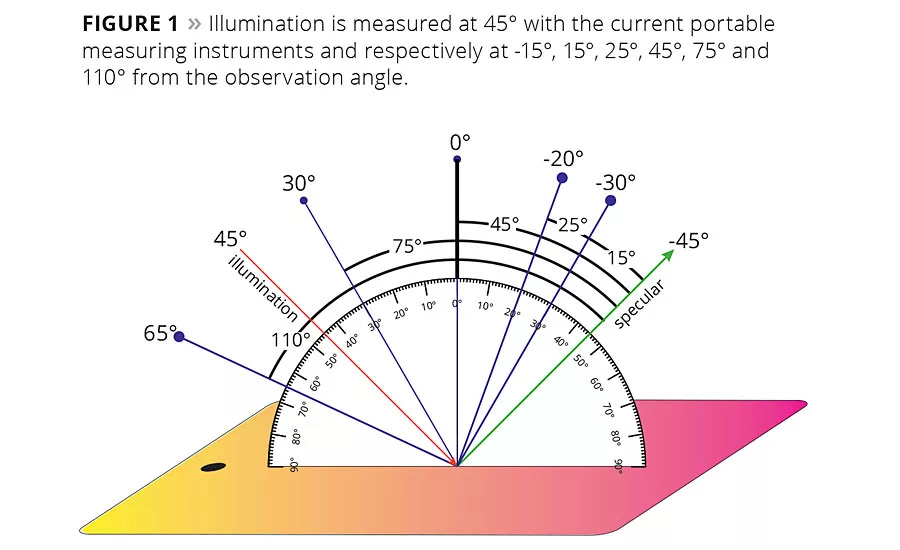

Figure 1

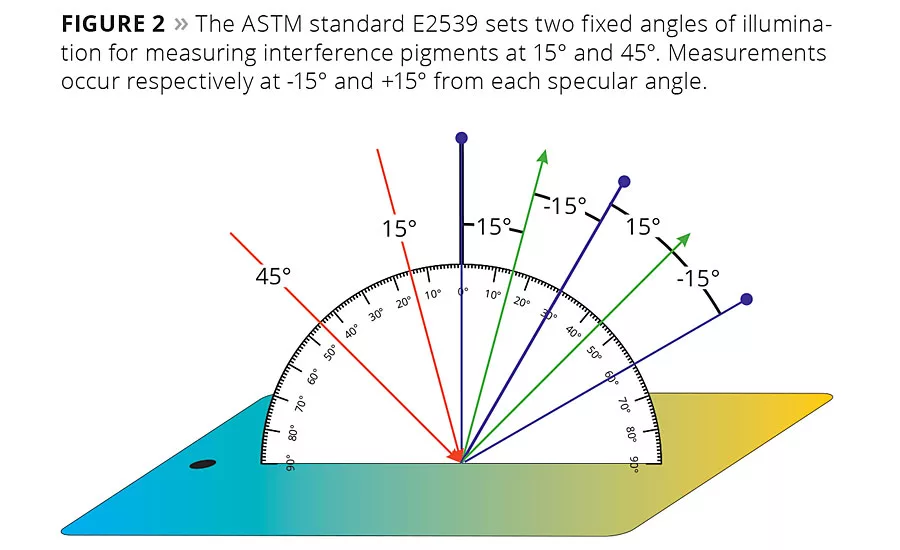

Figure 2

Figure 3

Figure 4

Figure 5

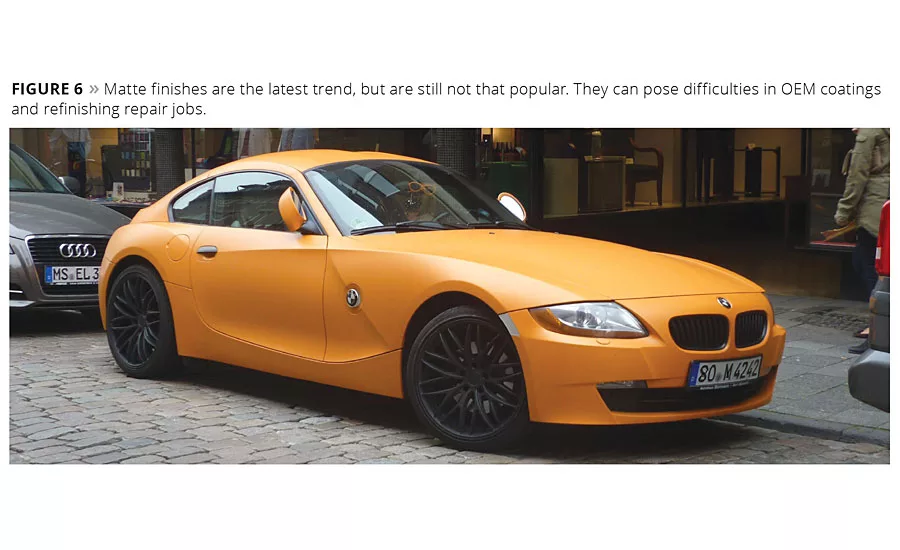

Figure 6

With the development of new effect pigments also comes the development of new measurement methods. This includes the multi-angle measurement of aluminum and interference pigments, as well as the description of perception effects. Thus, the various DIN, VDA and ASTM committees discuss these methods and how these phenomena can be explained. Based on these discussions, measuring instruments are developed that can be used in the workflows of relevant industries. The multitude of innovations with regard to pigment – but also in coatings and application areas – influence how a new standard color is created and what aspects are to be considered. Eight golden rules have been compiled to ensure effective color creation.

1. Mind the Geometries!

In most cases, modern automotive coatings have an effect that changes either the lightness or both the lightness and color. Depending on the location of the illumination and the location of observation, geometries result that relate to the appropriate angle.

The light – usually the sun – illuminates the vehicle under a quantifiable angle and is reflected from it at the same angle to the normal. The normal is perpendicular on a point of the car body where the light is reflected. Together with the illumination, the normal and the gloss (= reflected light) form a layer. In this layer, the angle is defined by the normal: illumination of 45° means that the light source illuminates the vehicle from the normal at an angle of 45°. The illumination angle is therefore 45° (Figure 1).

The specular angle corresponds to illumination angle; for practical reasons, the angle is preceded by a minus sign, which is physically incorrect. If one were to observe the gloss of the vehicle, the aspecular angle between gloss and observation would be 0°. When moving away from the gloss, the aspecular angle becomes greater. Instrument manufacturers refer to this aspecular angle, which usually is 15°, 25°, 45°, 75° and 110°. Accordingly, the corresponding and absolute observation angles are -30°, -20°, 0°, 30° and 65°.

The ASTM E2539 Standard Test Method for Multiangle Color Measurement of Interference Pigments further proposes to also measure the other side of the gloss (Figure 2). This side is also found in the layer formed by illumination, normal and gloss, and is on the opposite side of that which is illuminated. For formal reasons, these aspecular angles are given a negative sign. Thus, the aspecular angle of -15° corresponds to an observation angle at -60° when illuminated at 45°. To distinguish between the positions, the prefixes “cis” and “trans” may be cited. “Cis” angles are located on the illuminated side, while “trans” angles are on the opposite side of the gloss.

Colored interference pigments (see next rule) are characterized by a shift in color when the angle of illumination is changed (Figure 3). Ideally, it is measured with a steep, classic and flat illumination at 15°, 45° and 65° from the normal, respectively at 15° from the specular angle.

2. Get to Know Effect Pigments

While colored pigments partially absorb the incoming light and partially scatter it undirected in all directions, interference pigments divide the incoming light. Particularly in the case of transparent pigment types one can recognize the intense reflection color and the transmission color, which is complementary to the reflection color. If a white light strikes the surface of a transparent interference pigment then it will be partially reflected. The other part travels through the high-refractive metal oxide layer and in turn partially reflects on the boundary layer to the substrate (e.g., mica, aluminum oxide, silicon oxide). This reflected portion exits the pigment parallel to the first reflection elements. Both components interfere with each other: displacement of the corrugation peaks and valleys occurs due to the longer path of the second element happening simultaneously. If there are successive corrugation peaks, the resulting peak is amplified. If the peaks and valleys coincide, the resulting peak is reduced. Light waves of certain wavelengths are selectively reflected depending on the thickness of the highly refractive layer (or layers), the refractive indexes and the angle of the incoming light.

Classical interference pigments change color in tight spaces when the lighting angle is changed. Modern interference pigments exhibit stronger changes, for example, from orange to red to green. Certain interference pigments also have what is known as a “sparkle” effect. This effect, which looks similar to when light reflects onto a choppy water surface, takes place with blends containing these pigments.

In a high vacuum, colored interference pigments are produced that generally have two distinct layers on both sides of aluminum platelets. The interference pigments include liquid crystals and pigments with structures that optically behave similarly to create a “grid” effect.

Aluminum pigments are generally divided into what is known as cornflakes and silver dollars. Due to their production, they have either an irregular structure or an almost round structure. The latter are much more vibrant and are mostly used for intense metallic colors (Figure 4).

3. Apply Specific Interference Pigments

These days, aluminum pigments are also added to finishing mixtures to achieve an optimum color mix with maximum chroma of the interference pigment and also a high degree of hiding power. However, it should be noted that both absorbing and aluminum pigments can strongly influence the interference effect, or even prevent it. When mixing a new color it is crucial to make sure that using an interference pigment only makes sense when it emphasizes or enhances the color. This statement also applies to the question of whether one should use a colored or white interference pigment. In most cases, interference pigments with dark-colored pigments (black, blue, green) will increase the chroma and lightness of the mixture. Chromatic pigments such as yellow and red, which possess a high chroma from the outset, are less suitable for blends with interference pigments.

4. Use Aluminum Pigments Wisely

Similarly to the interference pigments, there are differences in pigment size with aluminum pigments: fine pigments have a lower gloss (satin gloss), whereas coarse pigments have a much stronger gloss. However, increasing coarseness decreases the hiding power. In addition to classifications according to size, aluminum pigments are also distinguished according to how they were produced and the resulting optical characteristics: normal aluminum pigments are formed by atomizing aluminum, through which small particles that resemble potato tubers are formed. When they are flattened they become aluminum pigment and are given the name “cornflakes” because of their irregular appearance. When the atomization process with inert gas is carried out, the result is small beads that, when flattened, lead to round pigments called “silver dollars”. Aluminum pigments vary in sizes ranging from 11 µm to 24 µm for the cornflakes, and 14 µm to 34 µm for the silver dollars.

Silver dollar aluminum pigments have a stronger reflection of the light close to the gloss, which greatly decreases further away from the gloss. Both types of pigments are used in combination with interference pigments to control the gloss behavior of the color creation. This is portrayed well when the aspecular values of the lightness for the geometries of 15°, 25°, 45°, 75° and 110° are compared to the specular angle. Strong differences in lightness are particularly evident at the angles between 25° and 45°. It should, however, be noted that the differences between these angles are different sizes.

Additives can influence the reaction of aluminum pigments. In Figure 5, the lightness has been reduced with a flop corrector close to the gloss, and increased away from the gloss.

5. Select the Desired Color Range

If you want to create a new color with or without effect then you have to find out how. It is possible to start with a special-effect pigment and observe its reaction. If, for example, you take a colorful interference pigment, then the first step is to mix it with black to determine its effect. The next step is to repeat the experiments with a blue- or green-colored pigment or the corresponding paste. The actual color and effect possibilities of such interference pigments can be very quickly recognized in these combinations. From these trials, a number of ideas arise for new colors, which can be prepared according to the OEM applications.

One can also control the desired color range in a targeted manner. It is common knowledge that modern series colors consist of a combination of different pigment types: the dominant pigment content will determine the overall color. An additional aluminum pigment regulates the shine effect of the mixture, whereby you can choose between fine to coarse aluminum pigments as well as between cornflakes or silver dollars. Additional interference pigments allow you to determine the behavioral effect of the complete mixture. Here again there is a large range of options that opens the door to many possibilities.

If, for example, you start with a blue-colored pigment, then white and colored interference pigments are mixed together. White interference pigments give a silvery effect, while color pigments create more color effect. Even gold or red copper interference pigments can be mixed to form a blue-colored pigment. Since they have absorbent elements, subtractive mixing behavior also occurs in such mixtures. Therefore, blue-colored pigments and gold interference pigments also produce beautiful green hues.

If you want to mix bright metallics or silver, then you can conveniently choose the aluminum pigment at the beginning. Since different types and sizes are offered, the decision for the level of shine and the coarseness of the complete mixture is made at this point.

6. Think in Color Systems

The portfolio of available color and effect pigments is so expansive that it is possible to create virtually any color. Nevertheless, it is important to always remember that these pigments are real and not of a theoretical nature. It is not possible to produce an ideal, neutral yellow. Yellow-colored pigments have either a red or green element. Also, there is not only one red pigment, but rather a variety of them. The reaction of red pigments with white or in mixtures is not ideal, and instead can turn to more violet and bluish hues. Adding a colored pigment to a mixture leads to a 3D-like change. It changes the chroma (intensity), the color and lightness: to make a color more blue by adding a blue-colored pigment also means changing the chroma and lightness.

Transparent interference pigments are generally arranged in a color wheel. Since they can be intermixed, new effects can be achieved in color creations. The various blends of the interference pigments respond to colored pigments just like the individual interference pigments.

Interference pigments with a strong color effect are singular pigments, meaning that they do not constitute a color system. Nevertheless, they can be mixed with the other interference pigments or with each other. The latter is, however, less advisable since it is quite likely that restrictions must be taken into account with regard to the effect.

7. Obey the Mixing Laws

Automobile finishes and many industrial mixtures are typically blends of various pigments or pastes. These not only have different colors and effects, but also behave differently when mixed: colored pigments such as yellow and blue are combined to make green. This is referred to as subtractive mixing. If, on the other hand, transparent interference pigments such as pearl yellow and pearl blue are blended together the result is not green, but a white. They mix additively.

Interference pigments divide the incoming light into two parts and absorb almost none of this light. In this respect, they can also be seen as the smallest sources of light, adding their different lights and colors when mixed. Pearl red and pearl blue make violet. Mixing red and blue color pigments does not create a sufficient violet hue, which is why red and blue are not mixed to make violet color creations, but instead violet pigments are used for this purpose.

To shift a color of absorbing pigments in a certain direction, you can conveniently use neighboring pigments or pigments with a similar tint: a blue does not become more reddish with a red, but with a violet. A yellow becomes more reddish when mixed with an orange. In this case, a red would mix too quickly into the red; and one does not begin with a greenish yellow, but with a reddish yellow.

Transparent interference pigments blend more or less ideally to create intermediate colors. Semitransparent or hiding interference pigments can also be mixed to achieve the desired effect. However, attempts and experience are necessary for successful results.

8. Find an Extraordinary Color Creation

Most standard colors like white, black and silver are normal color creations without much zest. Such colors help to attract a large number of car buyers while generally avoiding a discussion about tastes in color. Nevertheless, there are always requests for a special type of finish and color. For example, car manufacturers offer finishes with colored or matte clearcoats for which the reproducibility cannot necessarily be guaranteed (Figure 6).

For an additional cost, car buyers can usually order even the most unusual colors. This is not just about exotic colors with extraordinary effects. Sometimes even less-conspicuous color creations find their way into this special offer.

A metallic color may have a slightly glossy effect if fine aluminum pigments are used. By combining coarse silver dollar and fine cornflake pigments, a metallic effect can be “taken to extremes,” as one might say. Additional interference pigments can enhance this effect because this type of pigment reflects extremely close to the gloss.

Color effects that dazzle the onlooker can be optimally created using colored interference pigments. These pigments can be more or less haphazardly mixed together and with color pigments. Applying such pigments allows you to control not only the color effects, but also their chroma. All in all, there are so many fascinating interference and aluminum pigments available that their full potential is still far from being exhausted.

For more information, visit www.wrcramer.de, www.goniovision.com or email info@wrcramer.de.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!