Intumescent Paints: An Area of Growing Importance

The majority of multistoried high-rise buildings and public facilities (sports stadiums, airports, etc.) today have a steel skeleton. Although steel does not burn it still requires protection against fire as, without adequate protection, structural steelwork can reach a critical temperature of @ 500 °C within five minutes; and above this temperature steel starts to lose load bearing capability and may buckle or collapse, with disastrous consequences for the stability of the building it is supporting. Therefore the continued integrity of load-bearing steel structures is a key concern for building authorities.

A number of measures can be taken to protect steel from fire. These generally fall into the passive category and involve insulation techniques including encasing in concrete, or boxing within fire-resistant panels. However many designers these days prefer to showcase the steel skeletons of buildings - and for this, passive intumescent coatings are ideal.

Typically, intumescent coatings used to be solvent based, however in recent years water-based intumescent coatings have made significant inroads, particularly concerning the cellulosic-type fire protection. Water-based coatings offer faster drying times, allowing quicker coating and/or more coats of protection. They are generally suited for indoor environments although can be used for exterior protection with a suitable topcoat or “sealer”.

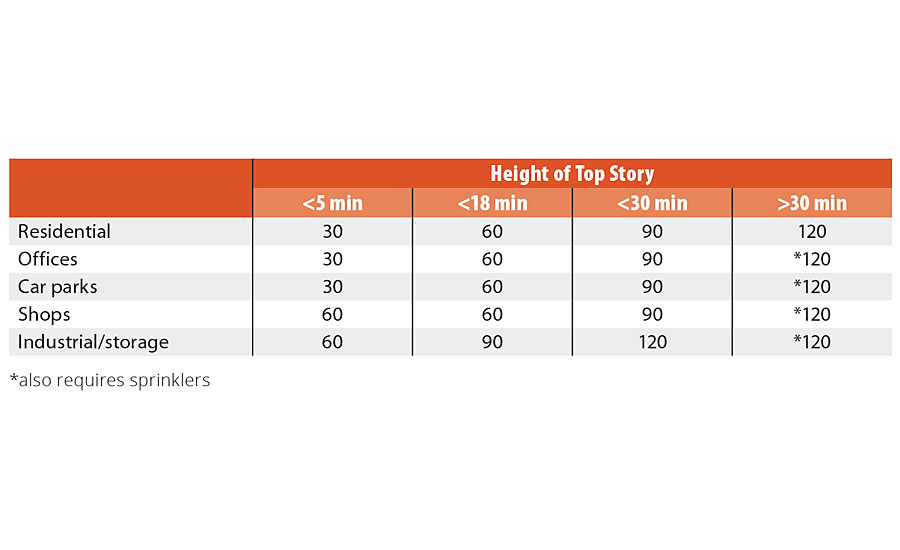

Intumescents can be classified into two categories: those fuelled by hydrocarbon sources (including so-called “jet fire”) and those fuelled by cellulosic sources (wood, paper, furnishings, etc.). Water-based intumescent paints are further divided into nominal categories depending on the length of fire protection required. Table 1 outlines the fire resistance times required depending on number of stories in commercial/domestic buildings in the UK.

TABLE 1 » Fire resistant requirements (minutes) - e.g. UK Building Regulations 200 (Document B).

How it Works

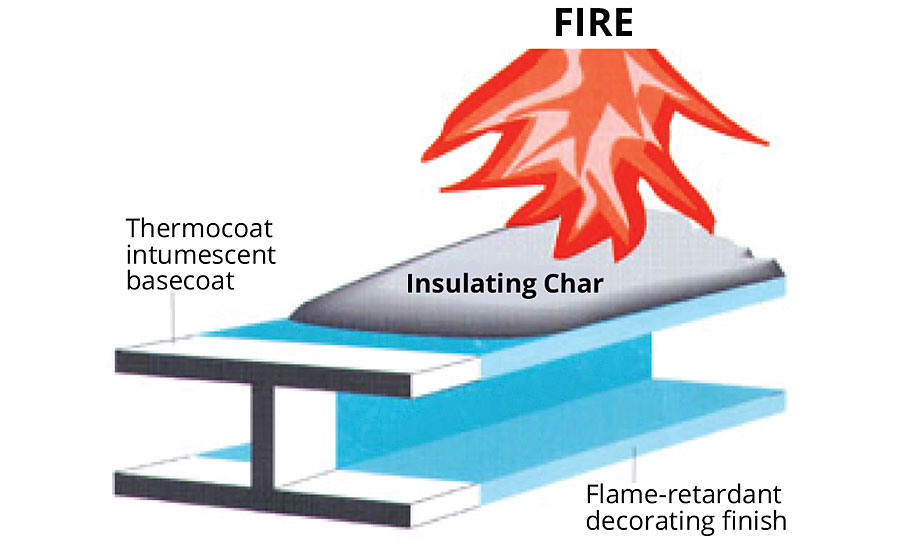

The basic principle of intumescent coatings involves a coating that reacts to rising heat by swelling up (intumescing, or expanding) to generate a heat-insulating char that slows or even potentially prevents the temperature of the steel reaching the critical temperature of 500 °C.

There are four key ingredients in a water-based intumescent coating:

- Acid donor (typically ammonium polyphosphate);

- Carbon source (typically polyols such as pentaerythritol);

- Blowing agent (typically melamine);

- Binding polymer (typically vinyl acetate copolymer).

The intumescent reaction is activated by heat at approximately 275 °C. It is an endothermic reaction that absorbs heat, emits inert gases and creates an effective insulation layer. Depending on the composition, such an intumescent coating can swell 10 to 100 times its original thickness to build a foam char barrier that insulates the underlying material.

This intumescent process may be divided into different steps, dependant on the specialist raw materials used:

- At temperatures above @ 250 °C the thermoplastic binder “melts” to form a liquid/viscous matrix within which further thermochemical reactions can take place.

- At around 275 °C ammonium polyphosphate (acid donor), which is the major ingredient of the intumescent coating, then begins to decompose, generating polyphosphoric acid.

- This polyphosphoric acid reacts with a carbon donor (usually pentaerythritol or dipentaerythritol) to form an inorganic/organic ester.

- A blowing agent (e.g. melamine) decomposes and releases gases, allowing the molten resin and ester to create a foam that forms an insulating barrier.

- As the temperature keeps rising, the ester decomposes to form a tough carbon char (Figure 1).

FIGURE 1 » As the temperature keeps rising, the ester decomposes to form a tough carbon char.

The resulting char insulates the substrates against heat. Thus, the protection time for the steel structure depends on the quality (density, adhesion, integrity, speed of formation) of the char as well as the char thickness. For 30- to 60-min protection a voluminous, light/delicate char is typically desired. For longer protection times the chars are typically more compact and tougher but, since the dry film thickness/number of coats is higher, the overall insulating effect is greater.

Other functional raw materials are also known to improve the performance: flame retardants may be used in order to reduce spread of flame rate and give self-extinguishing properties to the coating. In addition, melamine, primarily used as a blowing agent, is also a nitrogen-based flame retardant that can show excellent flame-retardant properties.

Addition of reinforcing materials (e.g. fibers) may improve drying properties of the paint (e.g. less mud cracking, higher low-shear viscosity), and also improve stability of the char. A fiber-reinforced char will withstand better the turbulent thermal currents generated within a fire, increasing the overall performance of the intumescent coating.

The binder is a key ingredient and has a number of roles to play. In the wet formulation the binder contributes directly (and sometimes solely) to the application properties and stability of the overall formulation. In the dry film the polymer binds the paint to the primer/substrate and also provides mechanical properties such as scratch resistance. As the coating intumesces, the polymer must first soften, then melt, at the right temperatures in order to provide a matrix throughout the process for the other reactions to occur. The right choice of the binder is therefore crucial; although many types of emulsion polymer can perform some of the required functions, the binders that fulfil the wide demands of intumescent paints most effectively are those based on vinyl acetate copolymers. The favorable thermal decomposition properties of vinyl acetate copolymers have been extensively detailed.1

Intumescent Paint Formulation

A statistical design experiment was commissioned to explore in more detail the roles and effectiveness of varying parameters (raw materials, PVC, types of steel, etc.) in producing intumescent paints. This study concentrates on formulating a “fit-for-purpose” 30-60 protective coating via the EN 13381 standard regime.

The initial screening of raw materials and basic parameters was done via multiple 200x150x5 mm steel plates in a 0.5 m3 furnace. All substrates were shot-blasted and pre-primed with a 2K epoxy-based industry-standard metal primer. All coatings were applied to equal dry film thickness. In all tests, a market-leading, 60-min intumescent paint was included as an internal standard to allow assessment of likely performance.

Stage 1 – Selection of Key Raw Materials

Only the basic key raw materials were included at this stage, and priority was given to the intumescing properties and basic assessment of resultant chars over flat steel plates. Approximate starting point ratios of the key raw materials (ammonium polyphosphate, pentaerythritol, melamine, binder) are well known and form the basis for the initial evaluations. In all cases water was added only to a level where good application was possible; all assessments were made at equal dry film thickness.

Evaluation of Ammonium Polyphosphate Level

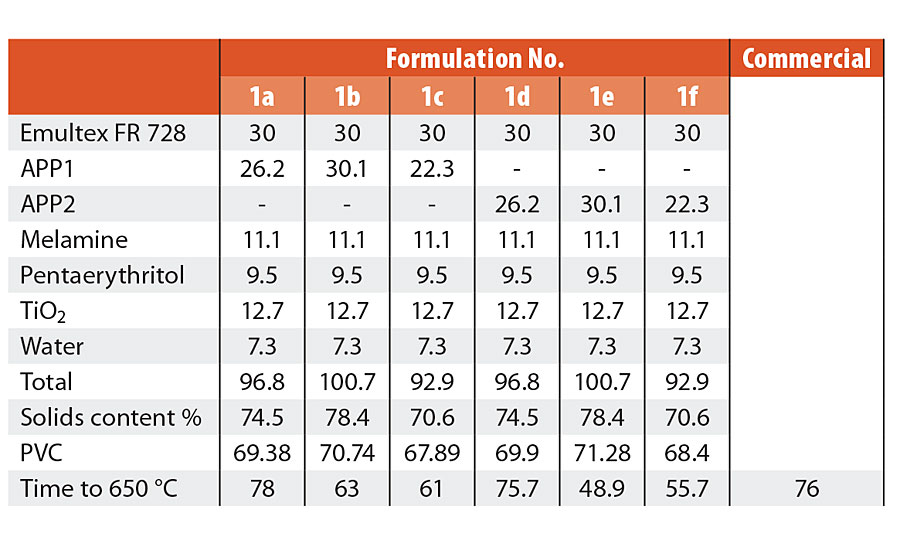

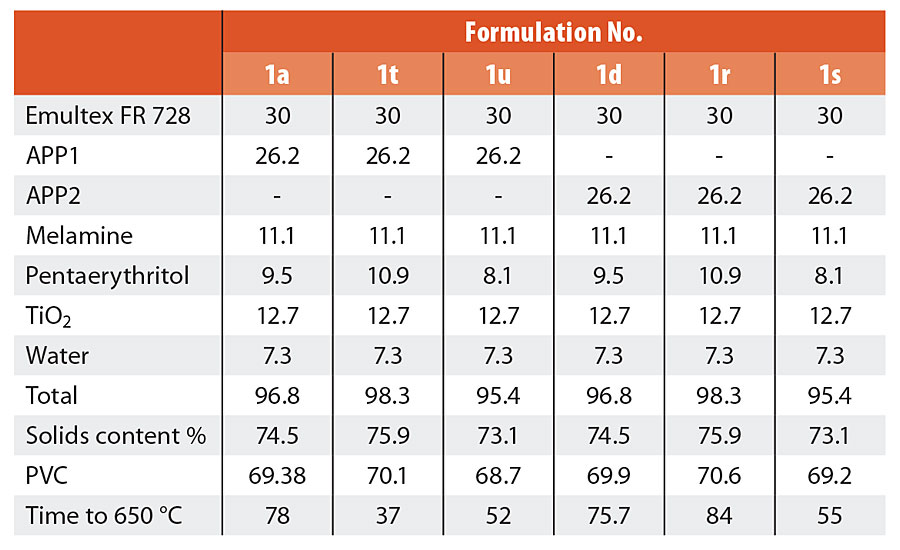

The basic formulation and modifications are given in Table 2, along with physical characteristics of the formulations and the fire resistance times. Two different ammonium polyphosphate (APP) grades were evaluated (from different suppliers).

TABLE 2 » Evaluation of ammonium polyphosphate level.

From the results it can be seen that the optimum level of APP in this speculative formulation is approximately 26.2 parts (Formulation 1c and 1d). APP1 clearly outperformed APP2 in this basic investigation.

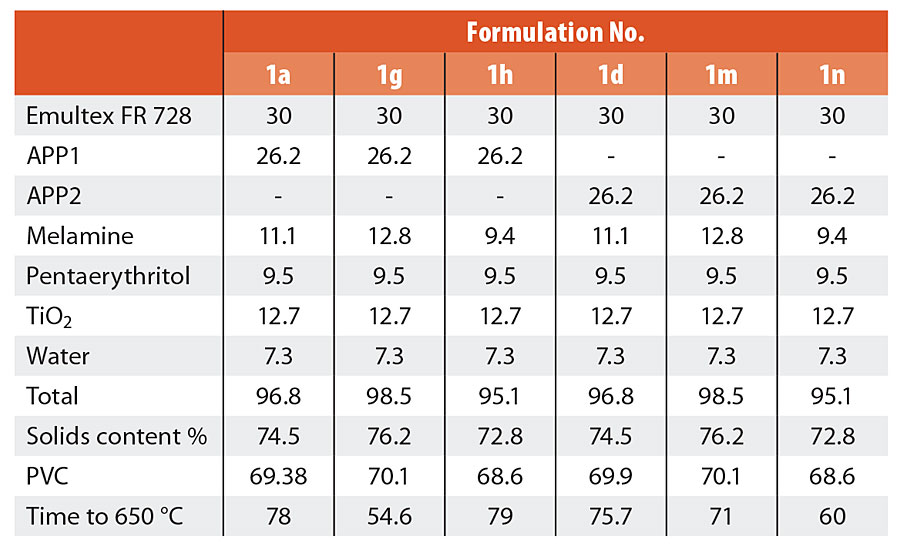

Evaluation of Melamine Level

From the results (Table 3) it can be seen that the optimum level of melamine in the speculative formulation is approximately 9.4 or 11.1 parts (Formulation 1a, 1h and 1d). Here the results were slightly more varied, however, with APP2 performing better than APP1 at higher melamine levels.

TABLE 3 » Evaluation of melamine level.

Evaluation of Pentaerythritol Level

From Table 4 it can be seen that the optimum level of pentaerythritol in the speculative formulation is approximately 9.5 parts in combination with APP1 (Formulation 1a). However, again the effect of different raw material compositions is becoming more apparent as a higher level of pentaerythritol was more effective with APP2. On balance of results it was decided to proceed with APP1 since this is a market-leading ammonium polyphosphate and widely available.

TABLE 4 » Evaluation of pentaerythritol level.

Evaluation of Ancillary Raw Materials

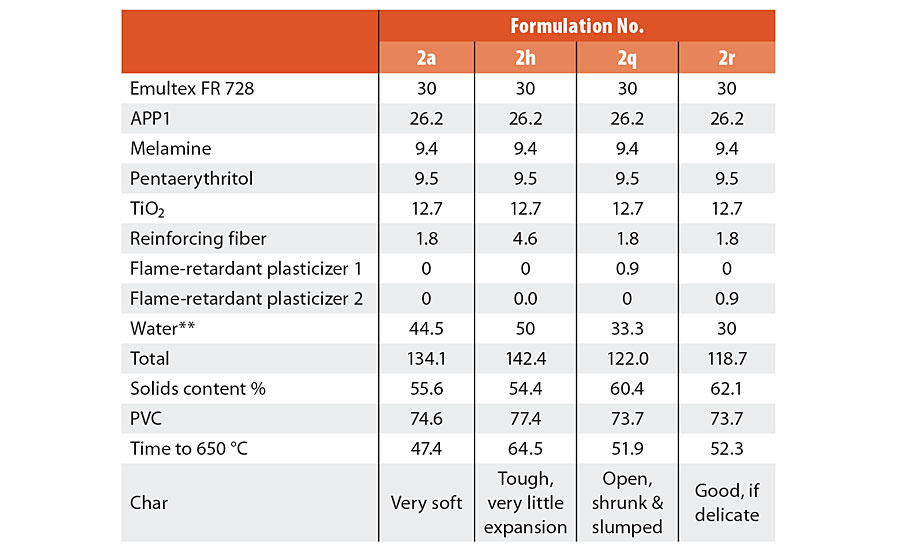

Reinforcing Fibers

Reinforcing fibers are generally added to improve the structure and robustness of a char. Table 5 details a comparison of two levels of a single reinforcing fiber. The developed formulation is intended for the 30- to 60-min application, where generally the char is light and voluminous. In this formulation the fire times were reduced with the use of such a compound, and the resultant chars, particularly at the higher level, were found to be compact and tough – characteristics more suited to longer fire protection applications (90-120 min). Therefore no advantage in using such a compound was observed for this particular application.

TABLE 5 » A comparison of two levels of a single reinforcing fiber and two different flame-retardant plasticizers.

Flame-Retardant Plasticizers

Flame-retardant plasticizers fulfil many functions, including modifying the initial liquid/viscous matrix and resultant char, and suppressing the initial fire. Table 5 also shows a comparison of two different flame-retardant plasticizers. Plasticizer 1 gave a poor char, which showed little structure and had collapsed and shrunk; however Plasticizer 2 gave a light, more uniform and fluffy/delicate char, which is better suited to the intended application.

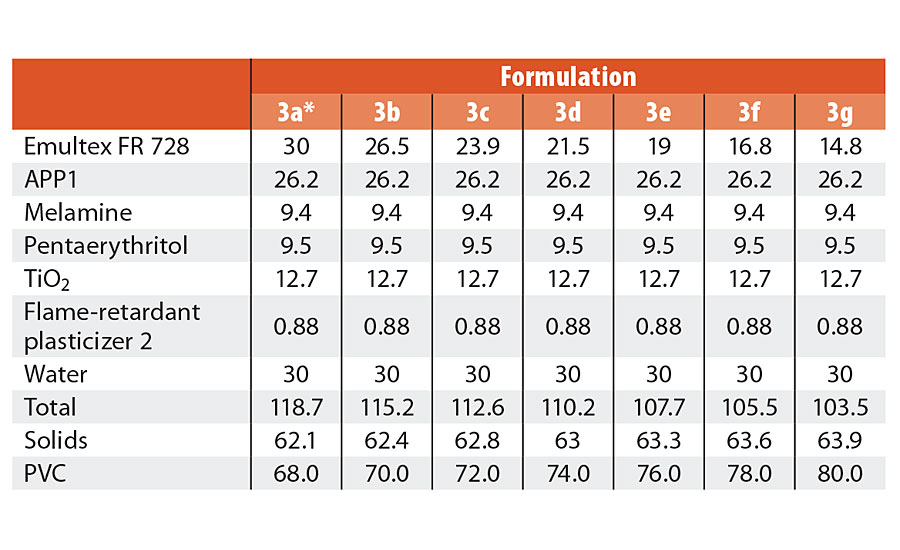

Evaluation of Binder Content/PVC

Generally intumescent paints are formulated to as high a volume solids as possible (while retaining stability) to give high dry film thickness; higher pigment volume concentration (PVC) generally leads to a reduction in the formation of undesired air voids in the char. Conversely the emulsion polymer is also expected to stabilize the whole system, and lower binder levels therefore also mean lower surfactant levels, poorer stability, potentially more problems during application, and perhaps a more restricted viscous matrix in which the intumescent reactions take place.

Table 6 details a ladder of PVC in the developing formulation. Initial tests were carried out over flat steel plates but further evaluated on “half-H” mini-steel sections. No issues were seen with the paints in the wet state or during application at 700 micron (dft). In separate application tests using a sag bar no issues of slumping, etc. were seen when applied from 100 up to 2000 micron (wet), suggesting the formulation holds up well in terms of application and stability at the PVCs tested.

TABLE 6 » A ladder of PVC in the developing formulation.

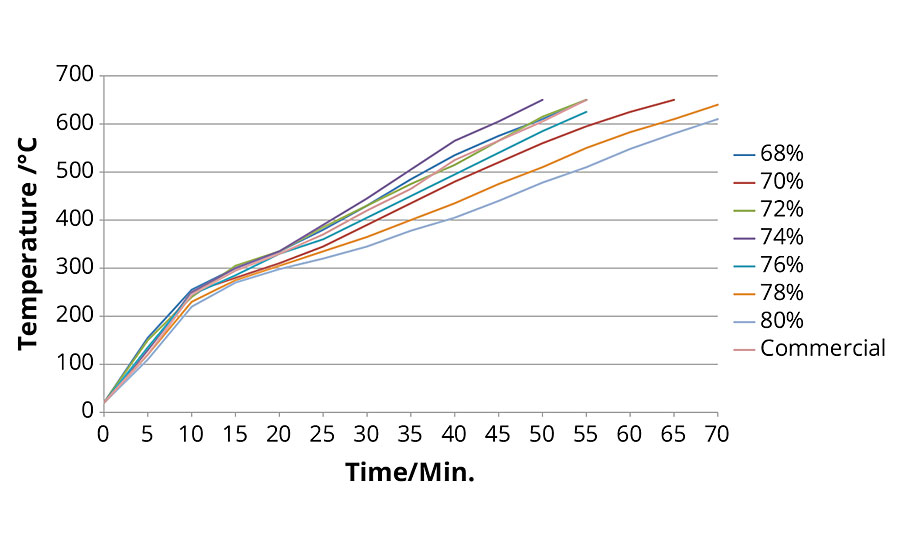

The corresponding fire resistance results (on the “half-H” sections) are seen in Figure 2. It can be seen that the trend is somewhat nonlinear; as the PVC is initially increased the fire protection time drops slightly; essentially, however there is little change. At the higher PVCs (78-80%), the protection times increased significantly - and inspection of the resulting chars showed that the structure became lighter, more uniform and voluminous, and with significant reduction in air voids compared to the lower PVC chars (Figure 3). Although the PVC could be pushed higher, some consideration would be required towards both the longer-term stability of the product and also application characteristics, hence 80% was considered an “all-round” optimum PVC for this particular balance of raw materials.

FIGURE 2 » Corresponding fire resistance results (on the “half-H” sections).

FIGURE 3 » At the higher PVCs (78-80%), the protection times increased significantly - and inspection of the resulting chars showed that the structure became lighter, more uniform and voluminous, and with significant reduction in air voids compared to the lower PVC chars.

Three-Dimensional Steel Sections

Steel plates and “half-H” sections are suitable only for basic formulation development. In order for a product to be considered for large-scale or even full testing it is important to confirm that the material performs well on a variety of section types and at different dry film thicknesses.

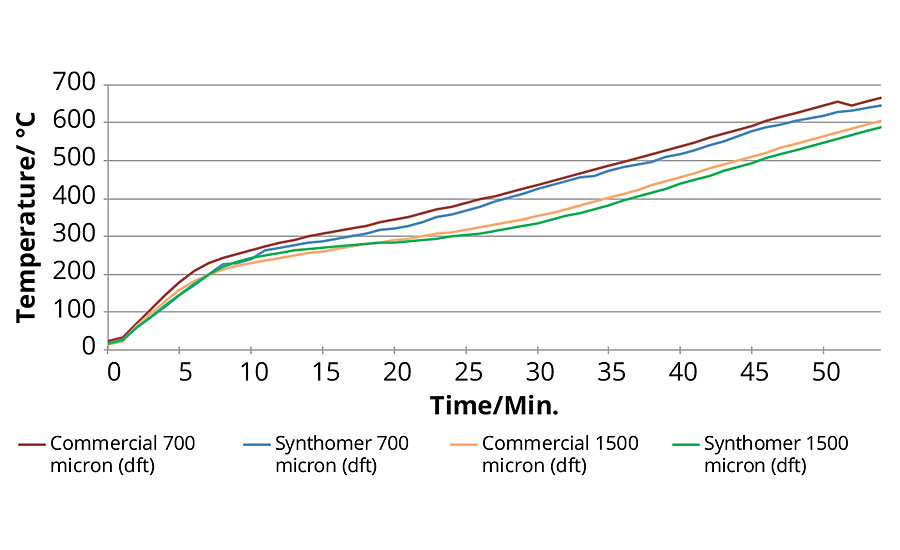

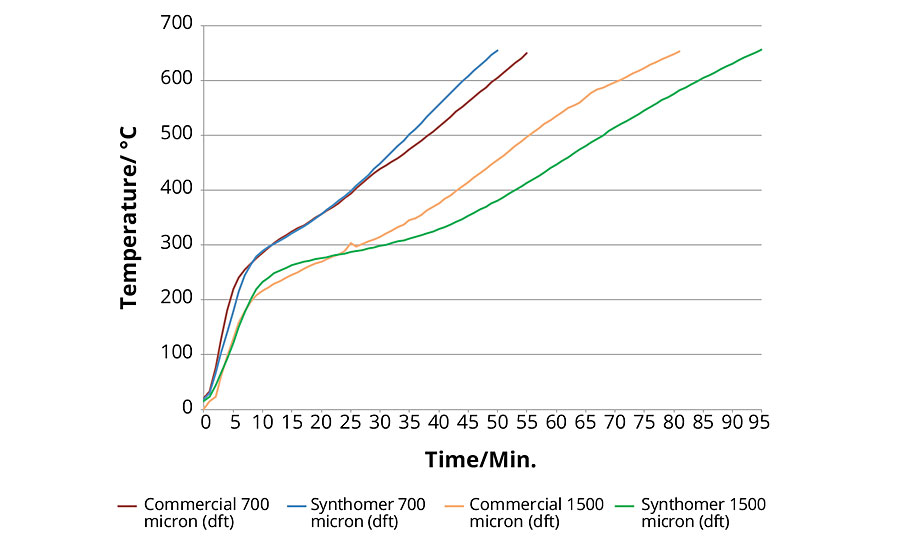

The typical section types are I-beams, H columns, circular hollows and square hollow sections. The preferred formulation was therefore applied to 1-meter sections of these types and at different dry film thicknesses (700 and 1500 micron dry). The series was replicated with the commercially available product to give comparable data. Each steel section contained at least four thermocouples to ensure there was thermal data coverage across each section and to identify where results may be anomalous.

It can be seen from Figures 4-5 that the derived formulation performs at least as well as the market product on all the sections tested. Furthermore, at higher dry film thickness the derived formulation gives superior performance; although the chars are typically light and voluminous (as expected of this application), the derived formulation has better structure and fewer defects at thicker films.

FIGURE 4 » Rectangular hollow section HP/A 165 at 700/1500 micron dry film.

FIGURE 5 » Circular column section HP/A 165 at 700/1500 micron dry film.

Summary

Through this study, the results demonstrate that:

- Choice of the primary raw materials, and the ratio of these, is key. Changes to the levels or using alternatives to these specific materials will significantly alter the end fire resistance properties.

- Secondary raw materials can also dramatically affect the overall performance.

- Rudimentary evaluation on steel plates is only sufficient for initial formulation development; a significant amount of refinement is required to produce a formulation that performs as desired over a variety of three-dimensional steel sections and at a range of dry film thicknesses.

The final stage in the “indicative” or pre-certification submission process is to verify the performance over 1-meter steel beams and columns via an independently witnessed test. To this end the derived formulation and the commercial product were both applied over epoxy primers to 1-meter H-beams at two different sectional dimensions (HP/a) and two column types. These sections are currently undergoing evaluation via an accredited third-party test house.

This study in no way guarantees certification can be achieved by the derived formulation, but should provide confidence that, correctly followed, the formulation gives comparable performance to a certified product already on the market at least through the pre-certification development phase.* Verification by the paint manufacturer and full certification procedure is still, however, required.

A protection time of 30-60 min is now the entry-level norm for these systems. Higher standards increasingly demand longer fire protection times yet at lower dry film thickness. Synthomer has therefore committed to the continuous development of its Emultex FR binders for the higher-performing intumescent coatings.

*The formulation as derived has been demonstrated to give a good indication of performance up to the stage tested and might be used to reduce developments costs. However Synthomer accepts no liability and offers no guarantee that the formulation, if followed, will attain full certification. For more information, e-mail simon.austin@synthomer.com or visit www.synthomer.com.

References

1 Pimenta, J.T.; Gonçalves, C.; Hiliou, L.; Coelho, Jorge F.J.; Magalhães, F.D. Effect of Binder on Performance of Intumescent Coatings; Journal of Coatings Technology and Research September 2015.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!