Why TiO2 Feedstock Matters

What do mining in Australia, labor issues in South Africa and mineral processing technology in China have to do with the global coatings industry? The answer is titanium feedstock, a little understood or appreciated element in the titanium value chain. This industry, known as mineral sands, is relatively small compared to other mining industries.

Although often considered a commodity, TiO2 products are highly specialized, and their intrinsic value is based on relative economic value and value in use, which are often not fully understood, even by industry veterans.

Titanium is the ninth most abundant chemical element in the earth’s crust, making up about 0.62% of it. Rarely found in its pure form, titanium typically exists as an oxide compound in conjunction with iron and other metal oxides. The principal minerals containing titanium are ilmenite (FeTiO3) and rutile (TiO2).

While titanium is relatively abundant, it is expensive because it is difficult to isolate in its pure form that is needed to manufacture titanium metal alloys or to convert to the pigment, titanium dioxide (TiO2). About 85% to 90% of titanium ore is refined into titanium dioxide (TiO2); the rest goes into titanium metal for welding rods and pig iron production as a co-product of smelting ilmenite.

TiO2 producers typically have sophisticated models to help them determine the best ore blends or mix to use. These models consider the TiO2 content of the ore or ore mix, the process chemical volumes needed and the waste produced from the ore blend selected. The cost of producing a ton of pigment is derived from these models and is used to optimize ore blends for cost and other reasons.

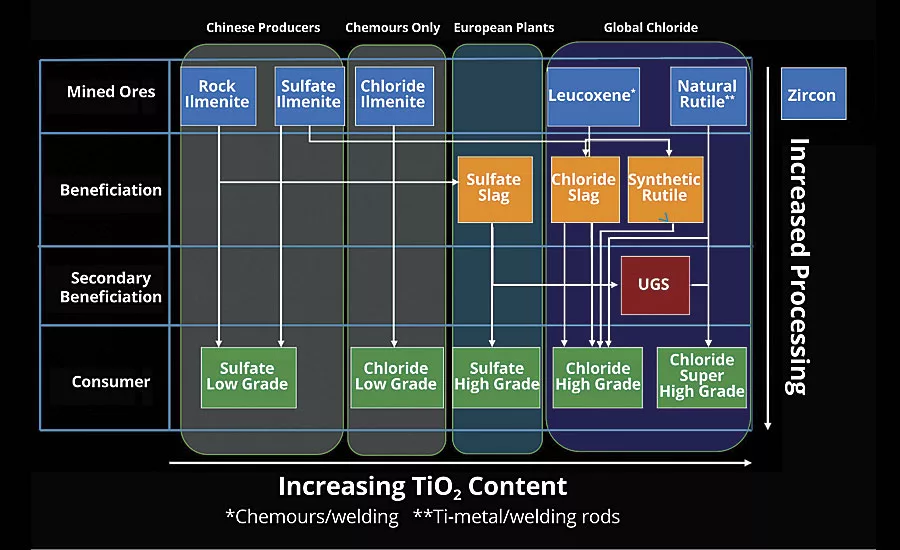

Figure 1 illustrates that sulfate producers and chloride producers have different ore selection criteria based on the capabilities of their process to remove impurities and produce high-grade pigment, the design of their plant in terms of their capability to use low-cost feedstock and produce at desired rates, and the requirements of their co-products or waste disposal permits.

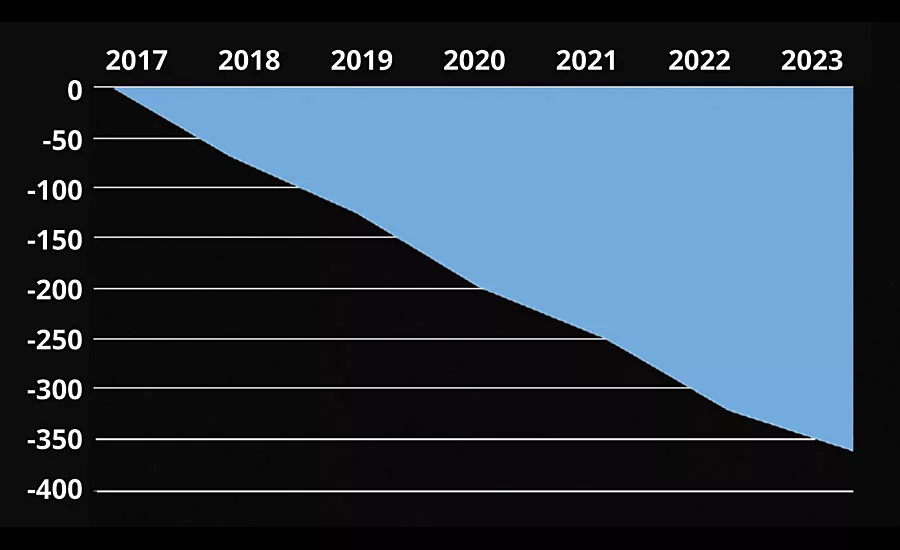

Change is coming. Current mines are depleting, requiring new mines. As is the case for most natural resources, the highest quality areas were mined first; now mining projects result in more trash and overburden, lower percentages of valuable heavy minerals (VHM), and VHM assemblages have lower value material. They decrease potential revenue with higher capital and operating costs (Figure 2).

The net result: miners will need higher prices for their products, costs that will be passed on to TiO2 producers. How fast will this occur? Figure 3 shows the depletion rate of natural rutile at existing mines.

Although global sales are estimated at 700-800 ktpa, new projects are not keeping up with depleting resources – which increases demand for less cost-effective raw materials.

The TiO2 industry needs titanium feedstock to produce the volumes required by the global coatings industry. Depletion will result in higher prices. Based on our hands-on experience and knowledge of the industry, TiPMC expects the cost to secure these critical feedstocks will be passed along to coatings companies and ultimately to consumers for the foreseeable future.

To subscribe to TiPMC industry reports and forecasts, see our ad in this issue or visit www.TiPMCconsulting.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!