"Strippables" Applied as Coatings, Not Films

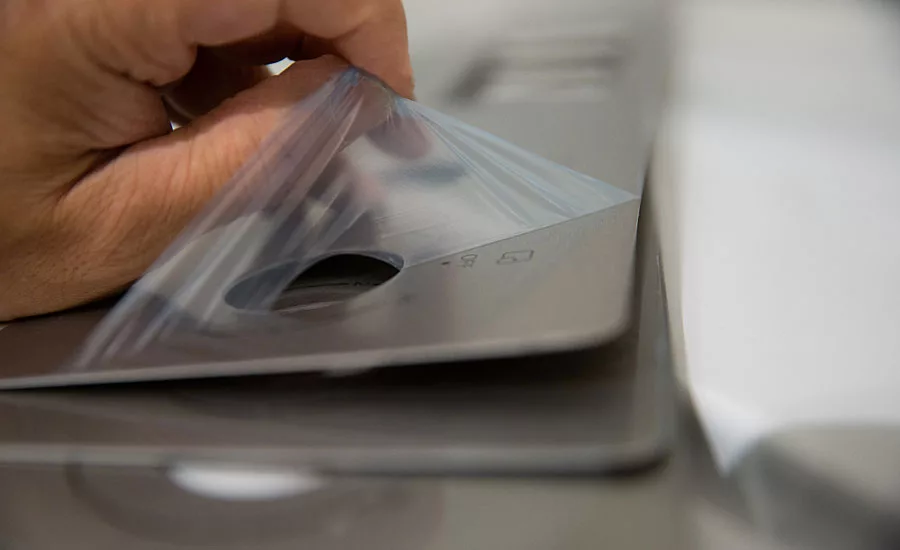

Temporary protective films are designed to protect everything from automobiles to appliances, construction products and housewares. Designed to be easily peeled off by the customer, these “strippable” films safeguard easily damaged surfaces during post processing metal fabrication operations, shipping, handling and installation.

Traditionally, strippable films have been applied to surfaces by hand or machine as sheets of film during or after manufacturing. The protective films are coated with a pressure-sensitive adhesive designed to bond to surfaces yet remove cleanly when no longer needed.

However, to match products of various sizes and characteristics, the films must be ordered in various widths and lengths. For uniquely shaped parts or products, temporary protective films can be die-cut to a particular shape.

The type and strength of adhesive on the films must also be considered. Care must be taken to ensure the films adhere properly without damaging or creating defects in the underlying coating’s integrity, gloss or color.

“If there is any particulate or even a dirt speck in the film during application or roll up, it can mar the coating beneath it,” says Dan Chin, President of Universal Chemicals & Coatings (Unichem), a custom coating and adhesives formulator. “You also have to ensure the adhesive does not alter the coating’s gloss, color or soften it in any way.”

For this reason, Chin says testing should be conducted to ensure compatibility of the adhesive on the back of the film or the liquid strippable to be applied with the underlying coating.

Given all these factors – the variety of film sizes and level of adhesion required – means that significant inventory must be held in stock, which increases overall costs.

As an alternative, a versatile family of liquid strippable coatings – applied in the same manner as color coatings or adhesives on coil processing lines – is helping to speed processing, eliminate film inventory and reduce costs. Unlike pre-cut protective films, the coatings are applied to whatever width of coil is required, in any thickness, and in formulations that ensure the proper bond is achieved.

Liquid strippables can be formulated with properties that can vary from flexible to rigid, depending on the formulation. In terms of coil processing, these coatings provide a strong, abrasion, moisture, and chemical resistant barrier.

The liquid coatings, which solidify into a protective film after heating and processing, are applied on everything from polished metals to plastics and even other coatings. The technology provides a wide range of adhesion options, which can be adjusted and controlled to meet the specific requirements for forming and stamping operations.

“After a strippable coating is applied, coil processors and manufacturers can carry out any post processing application like die-cutting, bending and even deep-drawing without damaging the surface,” says Chin.

He adds that strippable coatings can be designed with a wide range of capabilities.

“Strippables can be formulated to meet the performance standards of very specific applications, whether soft and pliable or hard and durable,” says Chin.

As an example, he points to a growing use of strippables for building products.

“After putting a finished coating on a building product like siding or roofing, you would put a durable strippable over the top to protect the finish from getting scratched or marred,” says Chin.

The automotive industry also utilizes strippables to protect vehicle surfaces during transport to assure arrival in pristine condition. In such cases, the coatings have been formulated to spray in thicknesses ranging from 3-4 mils. At these thicknesses, the strippable coating provides sufficient protection from rocks kicked-up by trucks and other vehicles on roadways.

According to Chin, in a typical application, a coil processor would apply the color coating in the first stage of the process, and the liquid strippable coating in the second stage.

“Applying the liquid strippable coating often occurs on the entire coil before the coil is slit to specific widths,” says Chin. “The coating can also be sprayed on pre-cut sheets or finished parts.”

Strippable coatings such as Unichem’s uniGuard product, for example, can also be applied to polished metals, metals coated with thermoset coatings, and some polyvinylidene difluoride (PVDF) coatings.

According to Chin, liquid strippables are adding increasing value as an alternative to film laminates on kitchen appliances and construction products (siding, roofing, garage doors, and roof & wall panels).

While such coatings are primarily applied during coil processing, the coatings can even be applied using screen-printing techniques. Screen printing the liquid strippable has been used to apply a strippable coating over appliance control panels. In this way, the coating can protect the precise area required.

There are a number of technologies available for products which need protection using liquid strippables so determining the various performance requirements is key to successful application and protection.

For more information, visit www.unicheminc.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!