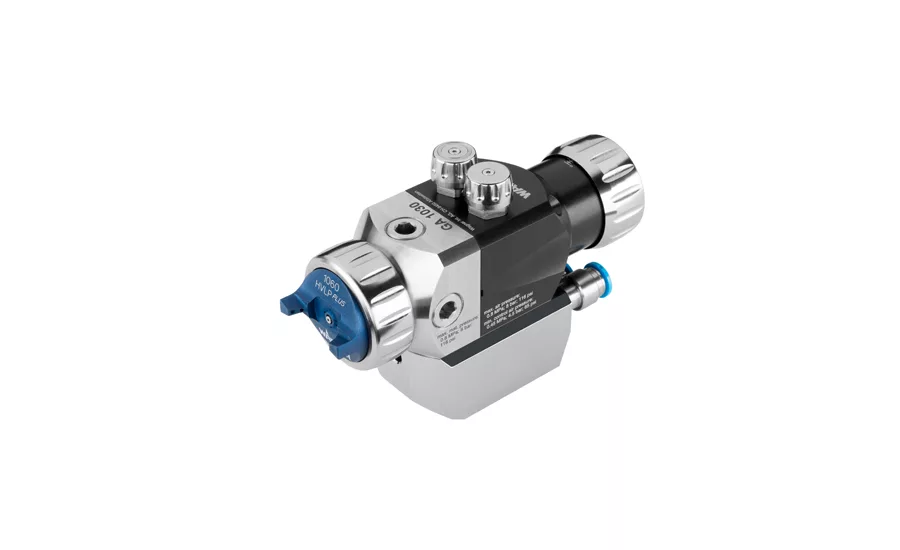

Air-Spray Gun

The TOPFINISH GA 1030 from WAGNER offers high reliability, minimal overspray and particularly low paint mist. Due to its modular design, the automatic airspray gun can be used for a wide variety of applications for coating work pieces made of wood, metal or plastic where a perfect appearance with high-quality surfaces is essential. "Thanks to a particularly large material passage of the nozzle, water- and solvent-based media can be applied just as easily as low to high viscosity materials and paints with a high solids content. Especially for coating with UV and highly abrasive materials, the automatic gun is available as TOPFINISH GA 1020 version with membrane seal - for switching times of less than 20 milliseconds and particularly fast position changes in the coating process," explained Peter Neu, Senior Product Manager Industrial Solutions at WAGNER.

The new gun can be converted into different variants in no time at all. Several air caps and nozzles are available for applying different paints. In order to keep storage and investment costs low, these and the needles are identical to the spare parts of the manual TOPFINISH airspray gun GM 1030P. The TOPFINISH GA 1030 can optionally be supplied with several circulation variants, with and without flushing valve and with various base plates. Optional rear or side connections support optimal movement. Several adapters are available depending on the type of mounting required and for robot mounting. In addition, there is a robot version with fixed needle stroke without air valves.

Overspray and thus material consumption are minimized by the optimized design of the air duct. This allows a transfer efficiency of up to 85 percent to be achieved. The material flow is regulated very precisely via a needle adjustment knob with micrometer screw. The gun is available with internal and external air regulation, via buttons on the gun or remote control. For a reliable coating process, the air supply to all variants of the new airspray gun is automatically interrupted during the coating process as soon as the needle closes.

Just like the manual TOPFINISH GM 1030P, the automatic TOPFINISH GA 1030 is equipped with a two-part nozzle consisting of nozzle head and nozzle nut, saving costs. In case of wear, only the nozzle head has to be replaced. All parts in contact with the material are made of durable stainless steel, and the needle has an additional wear-resistant and low-friction coating. The optimized, particularly durable packing and the specially coated needle support uninterrupted operation.

Visit www.wagner-group.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!