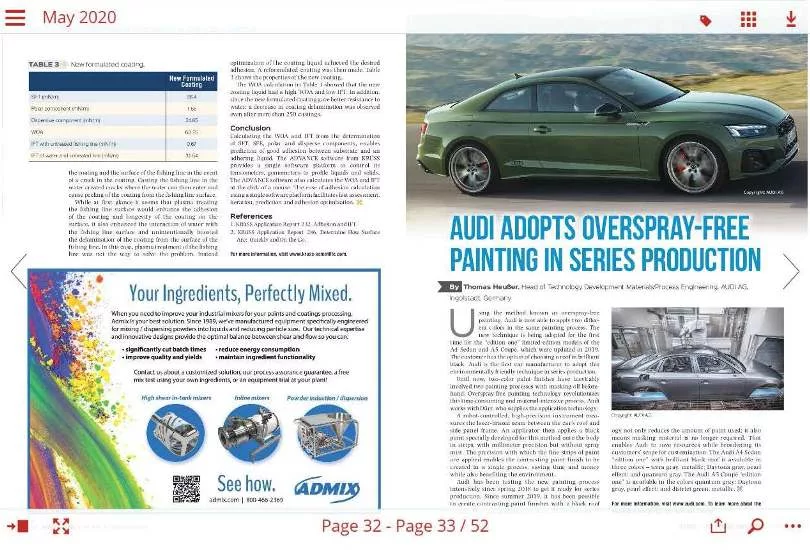

Audi Adopts Overspray-Free Printing in Series Production

Prefer the magazine experience? Subscribe to our digital edition here.

Using the method known as overspray-free painting, Audi is now able to apply two different colors in the same painting process. The new technique is being adopted for the first time for the “edition one” limited-edition models of the A4 Sedan and A5 Coupé, which were updated in 2019. The customer has the option of choosing a roof in brilliant black. Audi is the first car manufacturer to adopt this environmentally friendly technique in series production.

Until now, two-color paint finishes have inevitably involved two painting processes with masking-off beforehand. Overspray-free painting technology revolutionizes this time-consuming and material-intensive process. Audi works with Dürr, who supplies the application technology.

A robot-controlled, high-precision instrument measures the laser-brazed seam between the car’s roof and side panel frame. An applicator then applies a black paint specially developed for this method onto the body in strips, with millimeter precision but without spray mist. The precision with which the fine strips of paint are applied enables the contrasting paint finish to be created in a single process, saving time and money while also benefiting the environment.

Audi has been testing the new painting process intensively since spring 2018 to get it ready for series production. Since summer 2019, it has been possible to create contrasting paint finishes with a black roof within the series production process. The new technology not only reduces the amount of paint used; it also means masking material is no longer required. That enables Audi to save resources while broadening its customers’ scope for customization. The Audi A4 Sedan “edition one” with brilliant black roof is available in three colors – terra gray, metallic; Daytona gray, pearl effect; and quantum gray. The Audi A5 Coupé “edition one” is available in the colors quantum gray; Daytona gray, pearl effect; and district green, metallic.

For more information, visit www.audi.com. To learn more about the application technology, visit www.durr.com/en/.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!