Overspray-Free Painting

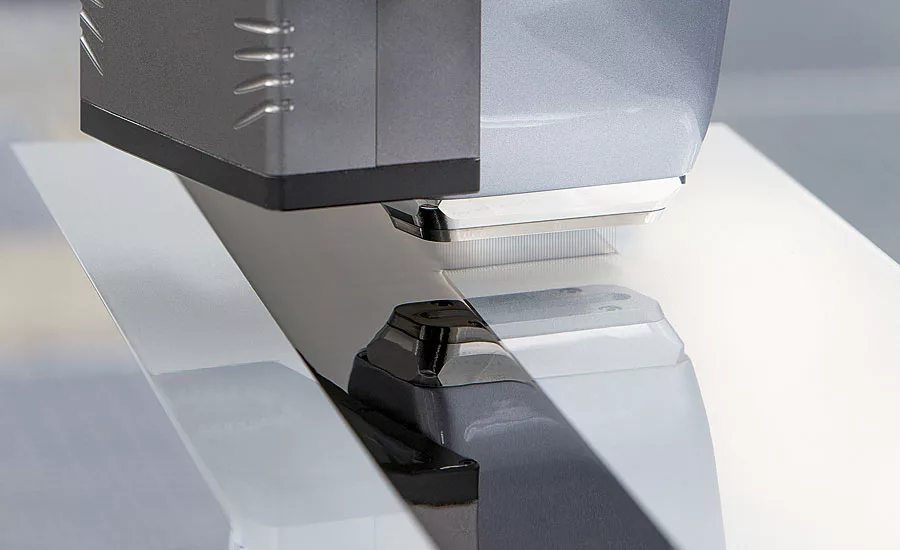

There are currently two dominant trends in the automotive industry: electric mobility and personalized vehicles. Dürr’s EcoPaintJet system for fully automatic car painting in two colors – without masking or overspray – is a perfect fit for this. The system has a number of benefits: it can be integrated into the painting line in new plants or added to existing plants as an additional module. The decorative coating can be applied to the already cured clear coat or following intermediate drying. The only small restriction is that the system can only process plain color paints at the moment, and no metallic paints. This is due to the applicator, the central element in the system. It is fitted with a nozzle plate on the underside. This plate has around 50 barely visible holes with a diameter of around one tenth of a millimeter. The paint is applied through these holes in parallel streams onto the body panels from a distance of 30 mm. This makes it possible for the paint to be applied with very high precision and absolutely no overspray.

When it comes to painting the roof of a vehicle, the challenge is that the surface is curved and non-rectangular. In addition, the bodies are not always in exactly the same place for painting. The EcoPaintJet system therefore measures the surface to be painted before every application using a two-stage measuring system in order to calculate body and positioning tolerances, and tailor the painting paths and paint application to them fully automatically. To this end, the system obtains basic information such as 3D body data and specifications for the robot paths offline. The corresponding software then corrects the measured deviations online to ensure custom guidance of the applicator. For example, it regulates the width of the paint application through appropriate horizontal rotation of the nozzle head, adapts the traversing speed to the degree of rotation – to keep the coat thickness constant – and tilts the application as appropriate to the slope of the roof.

Before the EcoPaintJet starts the first painting scopes, the system cleans and dries the nozzle plate and checks the number of open nozzles and the parallelism of the streams. If everything is in order, the application starts.

At this year’s customer event at the Dürr headquarters, visitors were able to see for themselves how the EcoPaintJet applies the paint with complete precision and no overspray. It can cover around 1.8 m² per minute. When operated on its own, the system can paint a body roof in just 120 seconds. To compare, just applying and removing the adhesive film for masking takes around 50 minutes. This high-tech process will allow the automotive industry to meet the personalization requests of customers more quickly and with top quality. The real added value offered by the new technology is reflected in the level of interest in the market.

Manufacturers of electric cars can equally benefit from the EcoPaintJet: some electric cars are slightly higher than conventional models since the battery is installed in the floor assembly underneath the passenger compartment. However, many customers want sporty and streamlined vehicles. This illusion can be achieved optically by applying stripes in a dark contrast color at the transition from the roof to the side panel and at the sills. The EcoPaintJet is ideal for this also.

Several car manufacturers are currently testing the system, and a manufacturer in Germany is set to start using it in production in the near future. Dürr is already working on an enhanced version of this technology that will also be able to paint more complex shapes. This version will be called the EcoPaintJet Pro, and will offer individual opening and closing of each hole in the nozzle plate. This will open up even more possibilities for product personalization. Automatic application of more complex shapes should also be possible in the future, similar to a digital printer.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!