Nano Primer Helps Combat Rust

Low-VOC, Single-Component Primer Converts Rust into a Protective Layer

Prefer the magazine experience? Subscribe to our digital edition here.

Despite the proliferation of high-quality topcoats from a variety of leading manufacturers, advancements in primer technology have historically lagged behind – particularly for applications in highly corrosive environments. Most primers merely provide a mechanical bond, while initial ‘rust converting’ primers only encapsulate rust and suffer from high levels of toxicity due to volatile organic compounds (VOCs), making them an environmental risk.

Now, however, more advanced primers have been formulated that set a higher performance bar in highly corrosive environments. These reactive primers go beyond encapsulating rust to instead convert it to a protective material (iron phosphate) to minimize the risk of further corrosion. The chemical bond provides extremely good adhesion, high corrosion protection and also eliminates under-film corrosion.

The rust conversion formulation also differs from prior technologies by using a non-toxic, ultra-low-VOC, water-based acrylic polymer solution that can be applied with minimal surface preparation and without the need for sandblasting of steel and aluminum substrates.

Designed to work with most top coatings, the new generation of primers offers paint manufacturers an opportunity to apply their topcoats over a primer that will withstand the most challenging environments for painted surfaces and can be applied in an environmentally safe manner.

Simplifying Surface Preparation

Corrosion is no stranger to environments where moisture and extreme conditions prevail, such as tanks, piping, facility structures, marine and external infrastructure. Because of the limitations in primers, which represent a critical foundation for any coating system, coated surfaces in these environments have historically been unable to effectively deal with the eventual formation and future recurrence of rust.

As a result, maintenance personnel or contracted coating applicators must repeatedly utilize costly, time-consuming and environmentally hazardous surface preparation methods such as sandblasting to prepare surfaces to be primed and repainted.

However, not all environments can withstand the impact of sandblasting, which can damage critical surfaces and may be impractical for reaching hard-to-access areas such as cracks and crevices. Sandblasting is also expensive and time-consuming, and even poses its own safety risks to applicators.

This level of surface preparation is required because most rust primers on the market are sensitive to chlorides. “Even a minute amount of chloride on the steel can cause coating system failure,” says Martin Lawrence, Managing Director of New Jersey-based NanoRustX LLC, a supplier of advanced primer technologies under the NanoPrime brand. “This is why leading coating manufacturers demand extreme levels of surface cleaning (sandblasting) and removal of chlorides to a level of 5 mcgr/m 2 , which is nearly impossible to achieve. Even when sandblasting is used for surface preparation, flash rusting will still occur. Whereas this water-based acrylic polymer is not sensitive to chlorides or rust, and can actually neutralize them.”

According to Lawrence, a water-based acrylic polymer like NanoPrime utilizes phosphoric acid as its main reactive agent. The acrylic polymer base allows for some surface movement, as is typical with metal expansion and contraction. This non-toxic, ultra-low-VOC primer contains nano-polymers for added strength and durability, and has been tested to successfully coat surfaces from rust-free to up to 700 microns of rust.

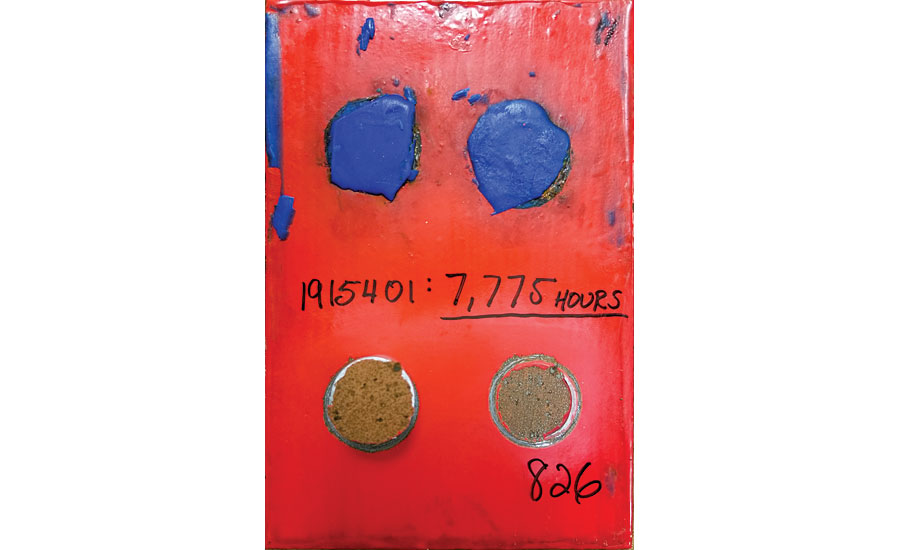

Further tests with a polysiloxane topcoat from a major brand for over 7,500 hours of salt spray have shown that the conversion of iron oxide to iron phosphate provides extremely good corrosion protection in the toughest environments (Figure 1).

Given that sea water contains 1.94% chloride, the lack of sensitivity to chlorides also makes this type of primer an ideal solution for marine operators that typically must go to dry dock before applying any type of coating. You simply can’t coat the substrate fast enough in a high-chloride environment such as marine areas and splash zones to prevent some level of chlorides on the substrate.

Unlike initial generations of rust-converting primers, the latest solutions perform equally well on clean, partially corroded and heavily rusted surfaces. Typically, a power wash (300 bar/3,500 psi) is all that is needed before applying to steel (clean or corroded), galvanized steel or aluminum in order to remove loose paint, dirt and grease. The primer can be applied to a corroded surface by hand brush, roller or airless spray gun on the substrate (Figure 2).

The water-based acrylic polymer primer works best with polysiloxane epoxy and polyurethane-based topcoats, and because the primer sits in a suspension, it requires only a 5- to 10-minute mixing before use. Typically, two coats provide sufficient protection, and as a water-based solution, it is also easy to clean up.

Lawrence adds that due to the presence of a significant layer of iron phosphate, when the coating is damaged, the iron phosphate prevents any under-film corrosion from occurring, and thus prevents a systems failure.

“A common failure of primers is not sufficiently protecting against under-film corrosion,” said Lawrence. “A primer must first form an effective chemical bond to the metal substrate. Without this, rust promoters like oxygen and humidity will creep underneath the primer, causing further corrosion. Most primers on the market go only as far as encapsulating the iron oxide, which is not 100% effective in preventing further rust from occurring.”

“When iron oxide is actually converted to iron phosphate through a chemical reaction, a meaningful chemical bond is created, along with a 10- to 15-micron-thick layer of iron phosphate that prevents any under-film corrosion,” he adds.

An Opportunity for Paint Manufacturers

Typically, paint manufacturers must carry a wide range of primers to be able to address different painted environments. Because of the performance capabilities of the new water-based acrylic polymer primers and their applicability to nearly all substrates, paint manufacturers have an opportunity to consolidate their primer inventory and provide their customers with a solution for the most challenging corrosive environments.

Considering these factors, the outlook for non-toxic, ultra-low-VOC water-based acrylic primers is promising. The opportunity now exists for paint manufacturers to work with primer developers to test the latest advancements in primer technology with their own topcoats to further validate the initial findings as part of their own painting systems.

For more information, visit www.nanorustx.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!