From Concept to Implementation: Anti-Ice Coating Technology for the Aerospace Industry

A manufacturer of de-icing systems brought up the idea of combining an active de-icing system with a coating that easily sheds ice. Ice formation on the leading edge of an aircraft is a common aviation danger, playing a key role in several catastrophic accidents over the years that have killed people and destroyed aircrafts. All commercial aircraft have a built-in ice protection system, which could be either a thermal, thermal-mechanical, electro-mechanical or pneumatic system. A common issue with de-icing devices is that they consume substantial power. Aircraft generally look to reduce power consumption, and with the advent of battery-powered aircraft, mechanisms or features that reduce power consumption are critically important. The aspect of reduced power is also relevant for battery-powered drones. Applying a passive anti-ice coating that functions synergistically with the active de-icing device is an attractive approach. The advantages are reduced power consumption, improved service life of mechanical components, lighter electronics and extra protection in case of failure of active device.

The challenge presented to the engineers and scientists at NEI Corporation was to develop and demonstrate a coating that exhibits durable anti-ice performance, and satisfactory wear and erosion resistance. More importantly, it needed to be practical for retrofitting in-service aircraft as well as be used by OEMs. In order to address the need, NEI developed its NANOMYTE ® SuperAi™ coating technology to have the following features:

- Extremely lubricating surface;

- Superior ice adhesion reduction factor;

- Thin coating (<1 mil or 25 microns), providing a lightweight solution;

- Durable anti-ice performance, suitable for permanent application;

- Room temperature cure;

- Easy application by spraying, dipping or brushing.

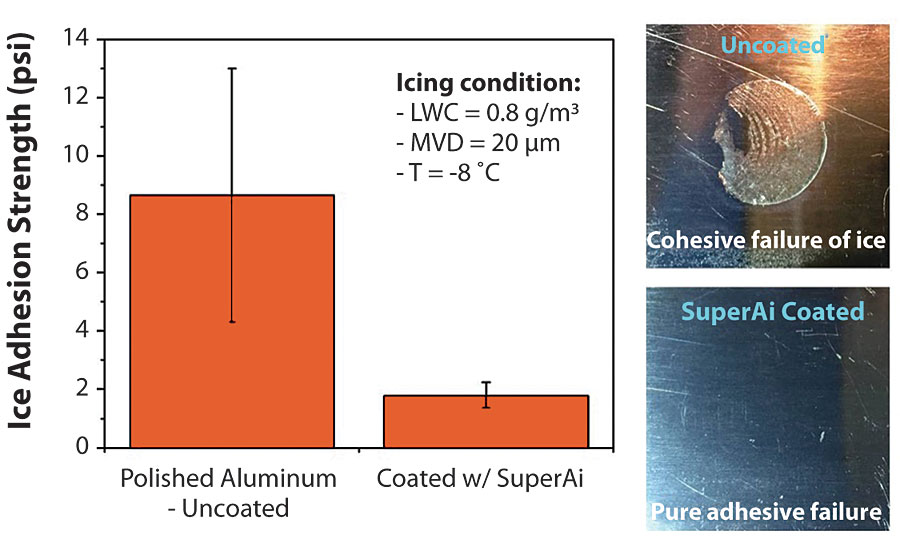

The development of the SuperAi coating started after numerous discussions with engineers at a major low-power ice protection system manufacturer. They brought to our attention the two basic technical requirements for an anti-ice coating to be applied on their de-icing systems, i.e., lower ice adhesion and durable anti-ice performance. We demonstrated both attributes after extensive experiments in NEI’s laboratory and iterative testing at an icing wind tunnel facility with prototype de-icing devices. The ice adhesion measurements taken at NEI were corroborated by work done at the Penn State Adverse Environment Rotor Test Stand (AERTS) facility, which repeatedly showed an ice adhesion strength as low as ~1.8 psi for the SuperAi-coated aluminum substrate – this represents an 80% reduction compared to an uncoated polished aluminum substrate. Figure 1 shows a pure adhesive failure when an ice column was pulled off the SuperAi-coated substrate. In contrast, a cohesive failure of ice is seen for the uncoated aluminum substrate.

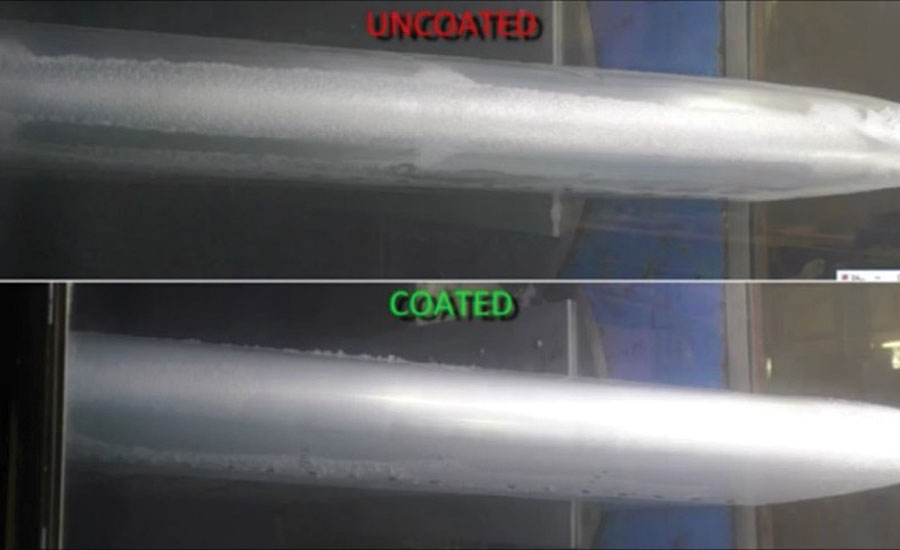

To demonstrate the enhanced de-icing efficiency of a de-icing device with the use of SuperAi, coated prototypes of electro-mechanical and thermal-mechanical expulsion de-icing systems were tested in an icing tunnel under simulated in-flight icing conditions at our collaborator’s facility. Figure 2 shows the SuperAi-coated leading edge being assembled with the thermal-mechanical expulsion de-icing system. We have repeatedly demonstrated that improved de-icing efficiency, along with a 45-70% reduction in power consumption of the active de-icing systems, could be achieved with the use of the newly developed anti-ice coating (Figure 3).

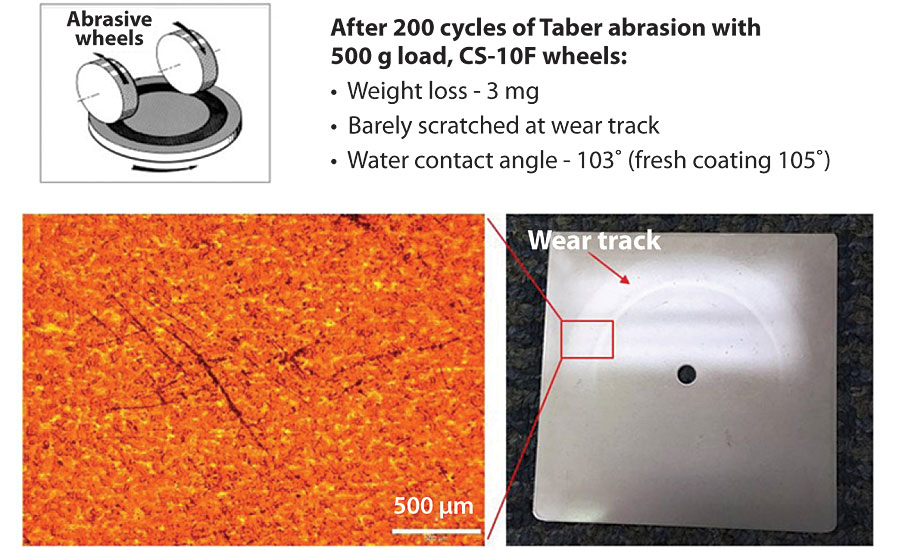

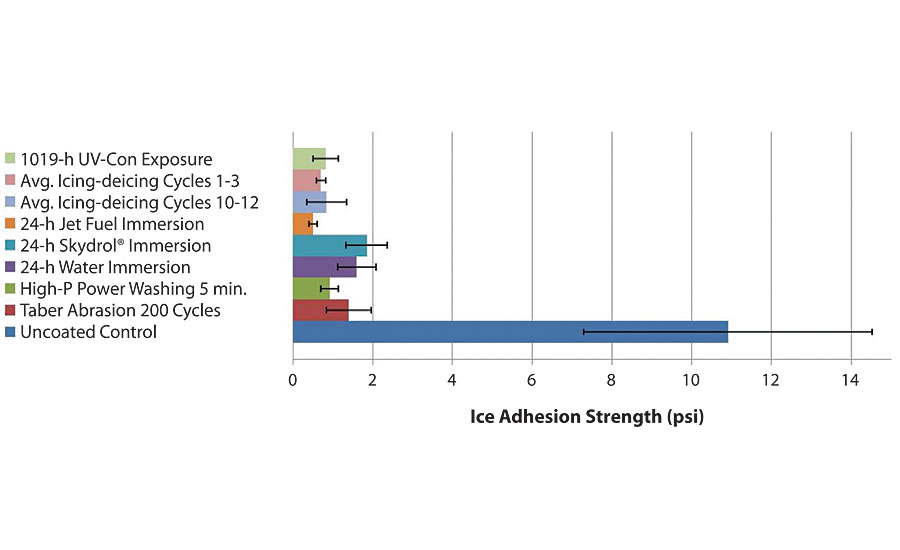

Abrasion resistance is of great importance for the targeted application. Figure 4 shows that the SuperAi coating was barely scratched at the wear track after 200 cycles of Taber abrasion. Note that the CS-10F Calibrase ® wheel used in the test is composed of a binder and abrasive particles, such as aluminum oxide and silicon carbide. The testing conditions simulate normal service abrasion and wear. Further, the contact angle at the wear track was measured to be 103 (vs. 105 of fresh, unabraded surface), indicating that the hydrophobicity of the surface was minimally affected by the abrasion. The ice adhesion measurement at the wear track showed that the coating remained highly icephobic after 200 cycles of Taber abrasion (Figure 5).

Other important aspects of an anti-ice coating for aircraft include its ability to resist rain erosion, chemical and solvent resistance, resistance to icing-deicing cycles, and weatherability. These aspects were investigated with various durability tests. As can be seen in Fig 5, the SuperAi coating could survive repeated icing-deicing cycles. There was little change in ice adhesion after immersion in jet fuel, Skydrol ® (an aviation hydraulic fluid), and water for an extended period of time. Further, the ice adhesion strength was minimally affected by abrasion, high-pressure power wash, and UV-Con exposure.

In summary, we were able to address an important need in the industry, using a disciplined and focused product development effort. The case study presented here is representative of the application-driven coatings development effort we undertake to address a problem or an opportunity. We work directly with customers and seek to develop, demonstrate and implement a solution.

Author’s Note:

NEI Corporation is extremely mindful of maintaining the confidentiality of its customer’s information, even without a non-disclosure agreement. Specific and sensitive information relating to customers have been withheld.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!