In the Dock with Selective Electroplating

Surface plating is widely used to repair or salvage critical components in the marine industry. As many components need disassembly, the repair process is typically carried out when the ship is in dry dock. Due to the nature of the plating process, this work is usually performed by plating or machine shops off-site. In a quest to add value through reduced downtime and labor costs, many shipyards are looking to bring this service in-house. Here, Mark Meyer, Sales Manager North America at SIFCO ASC, explains how shipyards can put key technologies in the dock which offer speed, portability and efficiency.

As everyone in the shipbuilding industry knows, repairs are a constant and inevitable fact of marine life, resulting in costly downtime and loss of earnings. Saltwater and harsh operating conditions cause corrosion and damage to key components such as pumps, valves and motors, necessitating regular maintenance or replacement. Commonly used to repair or salvage components and extend in-service life, surface coatings brings many advantages, including corrosion protection and wear resistance.

Just as there are a number of coatings – including nickels, copper, silver and nickel alloys – there are also numerous methods of application to surface coatings. Typically, key components are disassembled and sent to nearby service shops, with shipyards taking the delays and costs on the chin. However, driven by a desire to save time, increase revenue and add value to their customers, many shipyards are now looking to bring the plating process on-site.

Plating Methods – a Brief Comparison

There are three main technologies for applying surface coatings. The most common – tank plating – immerses components in an electrolyte solution. High Velocity Oxygen Fuel (HVOF) is a thermal spray technology that uses gas combustion or liquid fuel to spray molten materials onto the component surface. The third method is an electrolytic process called selective plating (also known as brush plating) where the operator applies high-quality deposits onto a specific area.

As with any technology, there are pros and cons for each, but of all three, selective plating lends itself particularly well to the demands and business models of shipyards. It is hardly surprising, therefore, that many are turning to the SIFCO Process®, a leading portable method of selective plating. There are numerous reasons for this, including performance, speed, portability, safety and cost.

Performance

Essentially, all three surface finishing processes deliver the same end result. However, there are small differences in certain mechanical properties including adhesion and thickness of the deposit.

Tests run in accordance with ASTM C633-79 on the SIFCO Process show that two commonly used nickel deposits had a bond strength exceeding that of the bonding cement. In addition, the hardness of finish with selective plating lies within the broad range of performance obtained with tank deposits. Similarly, its adhesion is comparable to tank plating in most applications. Metallurgically dense and free of defects, brush-plated deposits meet or exceed the requirements for tank electroplates, and far exceed those of thermal spray.

Moreover, selective plating is carried out at room temperature, eliminating the risk of heat distortion or hydrogen embrittlement, both of which can lead to parts failure. Whereas thermal spray provides a mechanical bond, the SIFCO Process creates a powerful atomic bond that is resistant to cyclical temperature fluctuations and sharp, direct impact. For this reason, the SIFCO Process has been widely adopted by naval forces across the US, UK and Japan, and is used on a range of components such as turbine casings, providing a metal-to-metal seal with less risk for thermal distortion than welding.

Speed

Clearly, one of the key reasons for bringing surface coatings in-house is to accelerate the process and minimize downtime. In this respect, selective plating scores highly. With tank plating, parts have to be removed and usually shipped to a plating company off site. Extensive masking may also be necessary, adding time to the process. Furthermore, certain parts may be too large for the tank to accommodate. With thermal spray technology, the application of the coating cannot be precisely controlled, so further machining is often needed to achieve the correct specification, adding a step to the process.

Selective plating avoids these complications. Compared with a deposition rate of 0.001" per hour for tank plating, selective plating is up to 60 times faster (0.015” per hour), accelerating the process. It’s also more precise, potentially eliminating the need for post-process machining. Most significantly of all, it can be applied in situ with only minimal disassembly and masking. Rather than the parts coming to the process, the process is able to go to the parts – and this is perhaps the key benefit of selective plating.

Portability and Ease

While selective plating can be applied in a dedicated workshop – or by an automated process – it can also be delivered as a truly mobile service. Unlike the relatively complex processes of tank plating and thermal spray, only four core elements are required: a power pack, plating tools, plating solutions and a trained operator. All the equipment can be carried into the dock, or on board the ships, and applied in situ, helping enhance or repair OEM components or salvage worn or mis-machined parts.

While many shipyards have SIFCO ASC’s certified technicians perform the repairs on site, a shipyard’s repair technicians and engineers can even take on the role after training – opening up the ways to upskill ‘tiger teams’ to add value to shipyard services.

Safety and Environmental

Following significant investment in R&D, SIFCO ASC has developed a range of well-engineered and proven deposits that deliver excellent performance, while posing minimal risk to either operator or the environment. In addition, selective plating consumes less energy and produces less effluent waste, adding to its sustainable credentials. The SIFCO Process is therefore a safe, sustainable and cost-effective technology.

Versatility

Suitable for a wide variety of sizes – from inside diameters as small as 1/4" through to components too large to be tank plated, the SIFCO Process offers a high degree of versatility.

This, coupled with ease and portability, make it an ideal process for a wide range of components and on-board repairs, including large, hard-to-move components such as propeller shafts, bearing seats and turbine casings. Other components suitable for selective plating include propulsion components, hydraulics, and electrical and structural systems, so it is suitable for many marine applications.

Automation

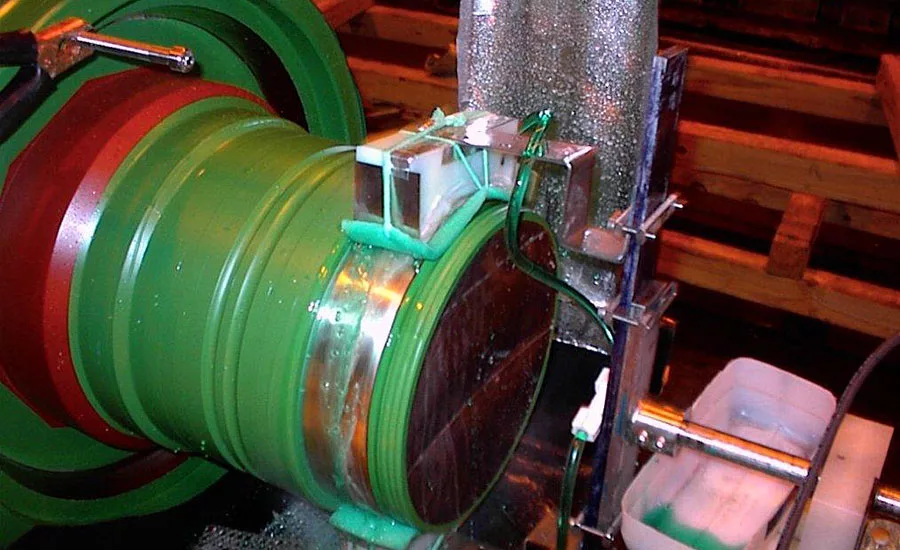

Although the SIFCO Process is typically a manual process, it can also be automated to meet the demands of higher volume plating applications, to include data logging and improved traceability. In automated applications, a computer program controls tooling and chemicals, while a robotic arm delivers consistent application during both pre-treatment and plating. Real-time data allows shipyards to monitor quality control while improving traceability and repeatability. Additionally, automation reduces ergonomic risk to the operator, limiting their exposure to chemicals used in the process.

Cost

Ultimately, cost will be the key driver in terms of shipyard investment, and many factors combine to make selective plating the process of choice.

There are multiple options when it’s time for an on-board repair. The first option, the shipyard can bring the plating operation in house. As selective plating requires minimal equipment and space, less capital investment in tools and personnel is needed. The second option, they can have one of SIFCO ASC’s certified technicians perform the repair on site. The portability of the process means it can be used for large, difficult-to-move components such as propeller shafts, reducing the need for expensive disassembly and shipping of components.

The selective plating process provides a permanent and cost-effective repair, with minimal need for additional machining. Shipyards can also benefit by not having to replace equipment, and instead use selective plating to extend the useful life of components and machinery. It consumes less energy and chemicals than other technologies and – most critically – it accelerates turnaround to minimize equipment downtime and production delays.

Quality and Assurance

SIFCO ASC is a world-leading business with a global footprint and track-record of R&D in the marine sector. The SIFCO Process is industry proven and written into shipbuilding specifications, including the American Bureau of Shipping, Mil-STD 2197(SH) and NAVSEA. First approved by the US Navy over 50 years ago, it remains the market leading brush plating process, supported by a global marine fleets.

In addition to providing a superior and more consistent coating quality, the SIFCO Process is easier and faster to apply, resulting in less downtime. Moreover, by performing the process in-house or in situ, traceability is improved and risks inherent in the supply chain are reduced.

The net result is improved production flexibility and efficiency and a reduction in total product cost. Critically, the SIFCO Process uses lower volumes of materials, minimizing EHS concerns. The process not only exceeds the fundamental requirements of shipbuilding manufacturing, and repair and maintenance processes, it also provides a full circle of benefits, including quality, durability, cost saving, portability and time saving.

Learn more about how the SIFCO Process brings protection on board at www.sifcoasc.com/marine.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!