Why Remanufacturing and Selective Electroplating Go Hand-in-Hand

Remanufacturing is on the rise. Already commonly used in the automobile, heavy equipment and off-highway vehicles (OHV) sectors, this manufacturing trend is expected to continue growing across even more industries and applications. This includes marine, aerospace, general industry and more, as businesses seek to reduce capital costs and extend the life of equipment and machinery.

Growth of remanufacturing can be further attributed to the constant desire to drive down the total cost of ownership of expensive equipment. Examples include landing gear in aerospace, diesel engines in OHV, pumps, valves and turbines in many industries, and much more. There’s a greater need now, more than ever, to minimize repairs and replacements, while enhancing agility throughout engineering processes – and remanufacturing fits this need perfectly.

The Ever-Present Need for Remanufacturing

In all industries, all equipment, from the smallest component to the biggest (and most expensive) machines are constantly subjected to unpredictable field conditions, harsh operating environments and sometimes even abuse, all of which combine to increase the risk of wear and tear, corrosion and damage.

If not properly maintained, many of these components – or entire pieces of machinery – may need to be scrapped, increasing capital equipment costs and downtime. These worn, corroded or damaged components contribute to the 73 million metric tons of ferrous metal, and millions more tons of non-ferrous metals and stainless steel in the U.S. scrap rate. This result is far from inevitable though – if site managers and manufacturers can find a way to head off component failure and remove the need for scrapping equipment.

This is where remanufacturing comes into play, returning OEM parts back to original specification – or better – for a longer, more reliable lifespan.

Extending Operational Lifespan without Lengthy Downtimes

It’s clear that remanufacturing is an increasingly prominent way to extend the operational lifespan of equipment. However, it is just as crucial to ensure that downtime is minimized when doing so, especially as the costs of such downtime can quickly rack up. In industries like marine and shipping, power generation and mining, any way to quickly, cost-effectively and sustainably enhance components, improve wear resistance and repair damage is key. Here, selective electroplating offers a vital benefit.

Selective plating (also known as brush plating) is a method of repairing and restoring critical dimensions and surface properties of worn components back to OEM standards, using an array of tried-and-trusted solutions, such as copper, nickel, nickel-tungsten and cobalt. Even more crucially, it can be completed on site, to reduce the downtime and cost associated with disassembly, transport and reassembly.

This is due to the ability of selective electroplating to treat specific areas of a component, with accurate, selective brush plating of materials onto localized surfaces and diameters, enabling in-situ repair and enhancement that is typically faster than alternative surface coating methods.

As opposed to tank plating – the other major method in electroplating –– brush plating does not require extensive masking or special fixtures. It can also plate deposits between 30 to 60 times faster, with no risk of part distortion thanks to the process taking place at room temperature. All of which combines to make this particular remanufacturing process a faster, more cost-effective and lower-risk option.

The Science in Selective Electroplating

Given the continuous use and sometimes harsh direct impact experienced when equipment and machinery is in operation, selective plating needs to bond at the atomic level. This is something not provided by traditional surface coating methods, such as thermal spray, which only forms a mechanical bond.

To create this atomic bond, selective plating uses electrochemical principles: an electrolyte solution, containing ions of the deposit material, is introduced between the negatively charged plating surface and the positively charged tool. This is powered by a portable power pack, enabling precision control over amperage, voltage and duration.

When the tool – or anode – touches the surface, a circuit is created, with a cover material around the tool providing a reservoir to ensure even distribution. The current within the circuit causes the ions between the interfaces to bond – building up the plating layer and delivering a highly adherent and dense metal deposit.

Selective plating also allows for more accurate control of deposit thicknesses – often allowing parts to be plated to size with no post-machining. With the portable nature of brush plating, repairs are able to be undertaken either in the shop or on the job site – meaning accuracy is matched by a fundamental flexibility in the process.

Plating in Practice: Hydraulic Rod and Ram Defect Repairs

So, selective electroplating has been discussed in theory, but what happens actually out in the field? One example is SIFCO ASC’s work with a well-known heavy equipment and OHV manufacturer.

Due to size, cost and lead time, replacement parts or components for heavy equipment are not typically available on short notice. However, many components with wear and/or surface defects can be repaired, rather than replaced.

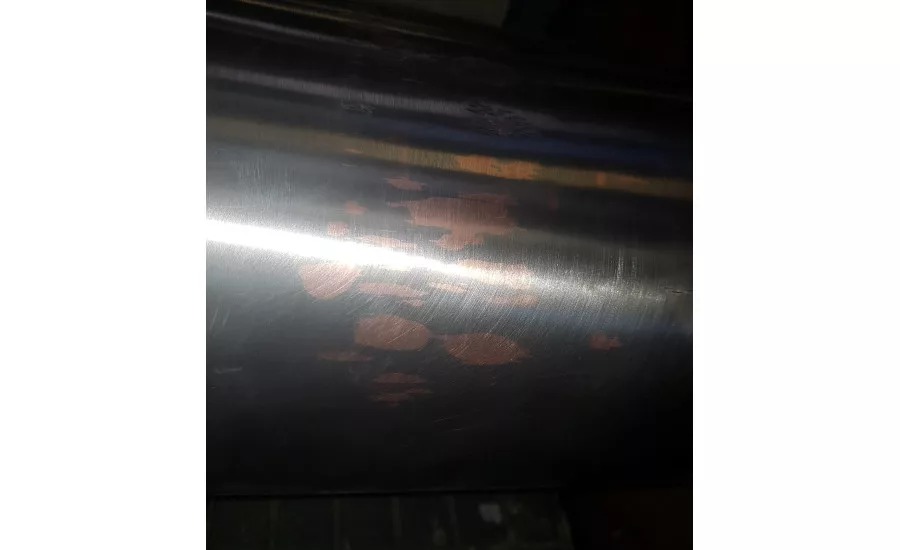

A common scenario is damage to hydraulic rods and rams, ranging from light scratches to deep impacts and corrosion damage. This can be permanently repaired by selectively plating using the SIFCO Process®. Defects are typically repaired with one or more layers of copper, then covered with a wear resistant deposit with good release or wetting characteristics.

These types of repairs are easily completed on rods and rams made up of carbon or stainless steel that have been plated with chrome or nickel. Copper is applied to the damaged area and then dressed back to just below the surface. Finally, a thin layer of cobalt-nickel is applied to a slightly larger area and then polished to match the surface texture.

Reducing Environmental Impact

Sustainability is at the heart of remanufacturing – and any way that we can cut down the demand for Earth’s resources is a welcome one. Brush plating fits the bill here – especially given its far lower impact compared to other surface coating methods.

Using less solution and chemicals, and generating very little waste, as well as reductions in the carbon costs of emissions, transport and shipping, it’s a more sustainable option at an ecological level. Even for workers’ health and wellbeing, the reduction in fumes and hazardous waste requiring disposal delivers a safer, healthier working environment.

Maximizing Uptime – and Minimizing Costs

In a fast-moving quarter of the world’s industrial landscape, remanufacturing and selective plating present a distinct way to do things better: returning vehicles, machines and equipment to operational effectiveness for a longer life of efficient and reliable service, with minimal downtime in the process.

Increased wear resistance, surface hardness and low electrical contact resistance, or corrosion protection, are just some of the benefits of the process.

With over 50 years’ expertise, a dedicated team of technical engineers, and an innovative R&D department, SIFCO ASC is the world’s largest selective electroplating and anodizing partner. To learn more, visit www.sifcoasc.com/remanufacturing.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!