R&D in the Coatings Industry: Why Formulators Must Go Back to Basics

mrs_veronik, Creatas Video+/Getty Images Plus, via Getty Images

Conversation between Merit van der Lee, Scientific Consultant and Team Lead, RheoCube, Amsterdam; and Dr. Ulf Stalmach, Co-Founder of the Smart Paint Factory Alliance, and with ORONTEC, Dortmund, Germany. Written by Jenny Maat, Marketing Team Lead at RheoCube.

When it comes to chemical formulations and rheology, the coatings industry has generally stood by its use of physical prototypes, or trial-and-error experimentation. While this approach has gotten the industry by so far, it’s definitely not future proof. Paint formulations may have remained similar over the years, but there’s been a dramatic increase in the special properties expected from these products. Regulations have changed with respect to ingredients and their use. The number of products available has also undergone change. For the average formulator, the coatings sector has become a lot more demanding to cater to.

Good formulations and the right ingredients are key success factors in any product development exercise. The price/quality paradigm has always prevailed in choosing ingredient suppliers, but a new range of decision criteria is fast evolving. New, innovative ingredients are needed to meet customer requirements, and it looks like sourcing them will be a challenge. Sustainability has become an additional issue, which formulators have to account for. In many cases, buying from the usual suppliers will no longer be an option — that will have a huge impact on R&D research programs.

It’s No Longer Just About Price/Quality

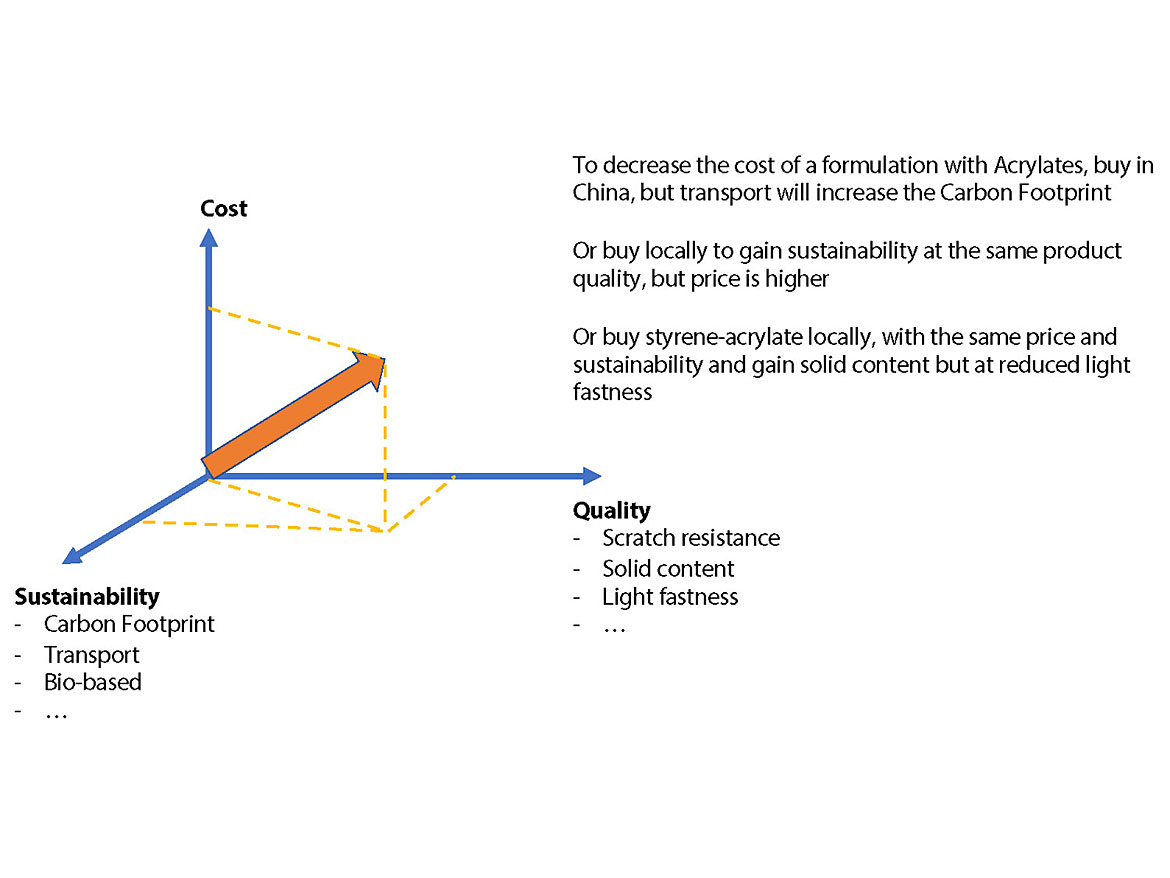

Take the price/quality mix as an example. These two elements must now be assessed in line with an array of other metrics such as sustainability, product application or health (e.g. solvent-free). To add to the complexity, each of those factors has, in itself, a range of subfactors. The list of considerations, and the impacts they have on one another, quickly becomes long and very unwieldy (Figure 1).

We move from a price/quality paradigm to an entire matrix. Accounting for sustainability, quality and cost alone create at least seven different factors to consider in buying a material. These additional factors include the footprint of a material used, the origin of production (transport), and method of production (energy, waste involved). It’s also important to look at factors related to how ingredients were developed, such as the number of trials run, material usage and the resulting waste produced — to name but a few.

In addition, formulators must now respond quickly to changes in availability of various ingredients. This undoubtedly complicates the formulation process even further.

While the importance of using safer, smarter or more sustainable inputs is by now well documented, exactly how all of this plays out in the lab is yet to unfold.

The Reality of Being Sustainable

In response to a more environmentally aware consumer and tightening regulatory environment, companies will increasingly chase sustainability scores. That quest, however, will have a knock-on effect on price, quality and other metrics.

A bio-based ingredient might sound good on paper, but it’s not just a matter of adding it into a formulation. It might not work at all from a product application point of view. The way in which it's processed could have environmental consequences, ruling it out if a company wants to legitimize its sustainability goals. Transport is another factor. Buying ingredients from faraway places won’t help to align with sustainability goals. Local sourcing is the obvious alternative there, but that could be much more expensive, which again impacts on the price factor.

What emerges is a complicated balancing act, where we go from optimizing on the traditional price/quality continuum to finding a global optimum. It seems however, that no matter what choice is made, formulators will struggle to reach 100% on all dimensions.

Each of these factors must be right, yet they affect each other and the overall success of fulfilling a growing matrix of needs. So how will this work in a market that’s increasingly competitive and regulated, where there is no compromise to be found anywhere?

Collaborate and Understand the Why

As new factors (beyond the usual price/quality) become crucial, formulators will need to change their modus operandi and adopt a bottom-up approach. Formulators, and indeed chemical experimentalists have to rethink everything, from ground zero. It will help to take a step back, really understand why certain formulations don’t work, and discover the potential that arises from that knowledge. Formulators must also become comfortable with collaborating outside of their sphere, sharing information and engaging with data sharing and data visualization technologies.

To find and use the right ingredients for product R&D, formulators will do well to work in a holistic, collaborative way. That means connecting with new and diverse parts of their department or organization (even outside organizations) to bring in the right expertise at a very early stage of product development. By doing so, they can avoid moving down the line with a prototype only to discover that it won’t make the cut on certain metrics, like the sustainability score.

It’s also key to understand ingredients in a way that has never been done before. The traditional way to overcome change has been to use trial-and-error, tweaking products, often by adding new substances to formulas, to arrive at a physical prototype that seems to work. The resulting knowledge is temporary and transient. It lives in people’s heads, and is often only accessible to a limited number of team members (if at all). What’s needed is a deep, shared understanding of formulations, why they work and why they don’t.

Without these crucial insights, coatings companies’ R&D programs, and therefore product development, will move too slowly. Successful formulating will require gut feeling to be replaced with science. It requires data sharing, so everyone works off the right information. That will deliver substantial wins, offer increased predictive power on experiments and help to isolate the physical experiments that just won’t work.

That capacity to isolate wasted experiments already offers a positive input to sustainability scores, by saving on the use of resources such as chemicals. It also underscores the need for a change in mindset. For many coatings veterans, it’s hard to see anything positive in not running multiple trials. That concept is new in an arena where the battle cry has generally been “I’ve done over X number of experiments to get to this point,” with a greater number of experiments suggesting greater credibility.

Formulators Cannot Do It Alone

Instead of going back and forth with trial-and-error experiments on the current formulations, it makes more sense to start from scratch. Formulators are at the forefront of this work, but they cannot do it alone. The good news is that they don’t need to.

Enhanced computing power has made digital R&D more possible than ever. Entire teams can benefit from a central source of truth on learnings about formulations. Companies can also retain organizational IP, rather than losing it when a formulator moves on.

R&D professionals can use smart tools to understand experimental results, and bolster their knowledge for the future. This could save years of chasing formulations that simply won’t work in the end. Discovering that at the very start will prevent wasteful spending and slow go-to-market.

The end goal is better products, for less cost. These must be delivered on time in line with customer needs, while managing to meet targets and satisfy legislation. Digital support can help chemical R&D to start off on the right foot, fast-track product development and stay ahead of competition.

The Way Forward

It’s a daunting task to respond to this paradigm shift. Time, new tools and a different way of thinking will be called for. However, there’s a very real need to invest in gaining deep insights on materials. That’s what will allow companies to reap the benefits of digital R&D and keep up with ever changing market demands.

The way forward has become more complicated and unclear, but in all of this there is a key — understanding the why. Formulators should be fearless in uncovering the reasons for an experiment's success or failure. They should use technology to track down the rheological sweet spot for their products and see the lab as a source of knowledge and collaboration. The resulting data will set research projects off on the right path and deliver huge savings for R&D, the company, the customer and maybe even the planet.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!