Photosensitive Haptic Coatings

for Athletic Footwear and More

Waterborne, high-solid, 3D haptic coatings 1 have enjoyed big market success in recent years. A main application field is athletic footwear. Exciting multi-color effects on multiple 3D coating levels, in combination with sensational touch effects and high-performance features, allow totally new freedom of functional design.

Now new photosensitive haptic coatings are introduced to the market. These coatings are based on fully waterborne PUD resins with high elasticity, flexibility and superior bonding properties, and are usually applied on textile substrates. Based on nanoscale oxidized graphene particles – graphene oxide (GO) nanoparticles – highly photosensitive coating layers can be developed. The GO-doped haptic layers show high transparency and are nearly colorless. When the GO-doped coatings are exposed to natural sunlight or artificial UV light, the GO nanolayers start a chemical reduction process, and dark black reduced graphene oxide (RGO) nanolayers are produced. 2,3 Relatively large sp2 islands are formed, totally changing the absorption properties of these coatings and turning them (over time) into a dark black color. By using masking devices, the coating on athletic footwear can be partially exposed to UV light, and design patterns can be created by selective UV exposure. Furthermore, the GO-doped haptic coatings can be further pigmented with standard pigments or with iridescent special-effect pigments. During the time of UV exposure, creative color effect changes can be achieved, changing the appearance of a surface over time.

Introduction

Customers are first attracted to products by their visual appearance. The color design of athletic footwear, therefore, plays a crucial role in product sales. Single colors or the right combination of colors will make a product successful. Today’s consumer markets demand emotional excitement for products, and quickly run into aesthetic fatigue if nothing is perceived as special. Photosensitive haptic coatings will add a type of living color effect by responding to the environment and the consumers’ use habits by changing color. Whenever photosensitive haptic coatings are exposed to sunshine, a slow color change process begins, and the coating darkens. If applied to athletic footwear, the color will be a little different every sunny day the shoe is used. The color will gradually change over time, and the consumer can observe the color change every day, curiously waiting to see the final color.

Following the new megatrend of consumer product mass individualization, photosensitive haptic coatings open up more opportunities for point-of-purchase individualization of athletic footwear and other products. Masking papers could be digitally cut directly in the shop, and individual designs could be created by UV irradiation devices. Stimulating inspiration, customers can have a sense of participation in the footwear-making process. This can increase the interaction between the customer and his/her footwear, and achieve real personal customization.

Application of Photosensitive Haptic Coatings

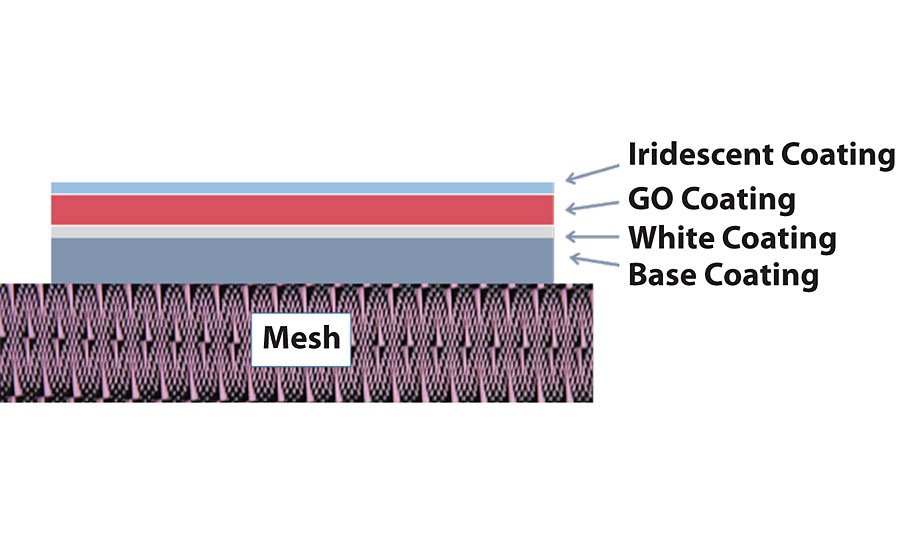

Photosensitive haptic coatings are basically applied in the same way as well-established haptic coatings – by manual or automatic screen printing technology. 4 For the process discussed in this article, the screen printing process was modified to allow high coating thickness of 0.2-1.2 mm for the base coat. Multiple layers are deposited, forming a 3D structured coating – potentially with multi-colors and multi-levels. Usually haptic coatings are applied on textile materials, polyester or nylon fibers, which are commonly used for athletic footwear. For the best photosensitive color effects, a special layer build up was developed, as shown in Figure 1. Multiple layers of transparent base coat are first applied, building up the required 3D coating effect and ensuring maximum bonding strength to the fabric. On top of the base coat, a first color coat, usually white, is applied to guarantee final color consistency. The GO-doped photosensitive layer is applied as the main effect coating, providing the color change mechanism in the whole 3D coating system. Usually the GO layer is applied with a thickness of 0.2 mm, allowing a strongly visible color change. Optionally, a thin iridescent color coating could be applied as a final top coat. Iridescent colors are especially interesting because of their strong visibility on dark backgrounds. Of course, the final top coat can also be modified to offer other haptic effects like soft touch, rough touch and matte or glossy effects.

Analysis of UV Photosensitive Mechanism of GO Coating

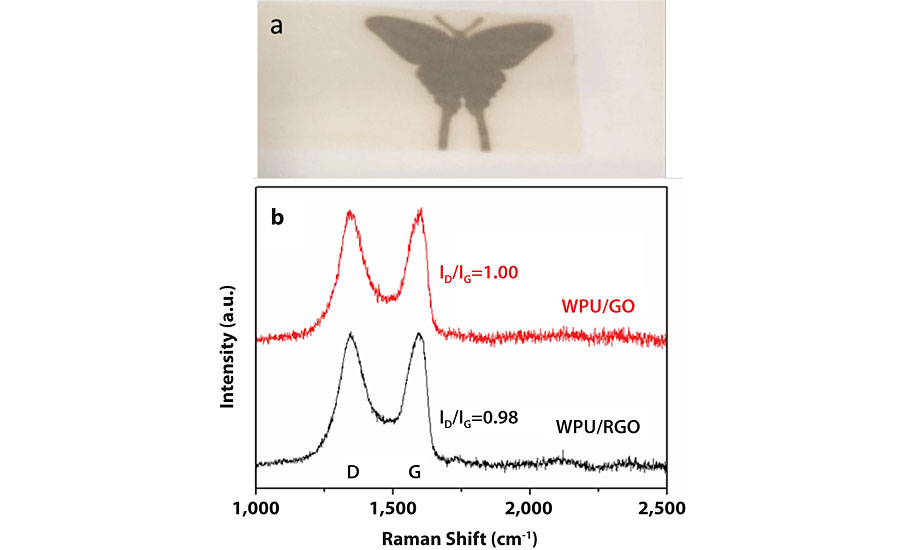

In a photosensitive haptic coating system, the GO coating is the most important part of the color-changing process. It is well known that GO can be gradually reduced under UV light, and during reduction a color transition from light yellow to dark black occurs. However, to date there are not many ideas for how this color change can be utilized in our daily life in consumer products. In order to study the photosensitive mechanism of a GO coating, 0.02 wt% GO was added in a waterborne polyurethane dispersion (WPU). A 0.2-mm-thick GO coating was prepared, which was light yellow and had a nearly colorless appearance. The GO coating was partially covered with a butterfly gauge and radiated with UV light for 30 min. The result is shown in Figure 2a. The uncovered butterfly design changed to a very dark (nearly black) color. Fig. 2b shows the result of a Raman study of the light and dark areas of the sample. The results of the original non-UV treated sample is labeled as WPU/GO and the darkened area is labeled WPU/RGO. The corresponding ID/IG value was found to be 1.00 and 0.98 respectively. This is a clear indication that some oxygenated functional groups on the surface of GO were removed. GO was weakly reduced photochemically during the UV irradiation.

Color Design and Features

Exciting color designs could be created by combining the photosensitive haptic coating with other color pigments. The resulting colors will gradually change in sunlight and significantly darken during UV exposure. To create great consumer products, color development has to be guided from two directions: 1) The initial color before UV radiation needs to be attractive looking, achieving an initial buy decision; and 2) The final darker color needs to be very attractive as well to keep the consumer happy with the product.

A great color-shifting opportunity is available with iridescent pigments. Interestingly, the color appearance of iridescent pigments looks very different on light and dark backgrounds. In addition to their iridescent effect, iridescent pigments show a light luster with high transparency on light-colored backgrounds, and a unique deep color (such as deep purple, deep blue and deep green) on dark backgrounds. Figure 3 shows a coating film on top of a black and white panel. The color change due to background color can easily be seen. The photosensitive haptic coating could now be used providing the background color. The GO-doped coating is basically translucent. Therefore, in our standard layer build up a white color coat is placed below the GO-doped coating. Before UV radiation is applied, the photosensitive coating system will therefore show a light-color, iridescent appearance. After UV radiation, the GO-doped layer will darken and will finally become black. Together with that gradually darkening of the GO-doped layer, the topcoat iridescent color will become more visible and will finally reach the color like on the black background.

Figure 4 shows a color compilation before and after UV exposure. It can be seen that the initial color is always a light color, and the final color after UV exposure is dark and shows a strong hue.

Color Change as a Function of Time and UV Intensity

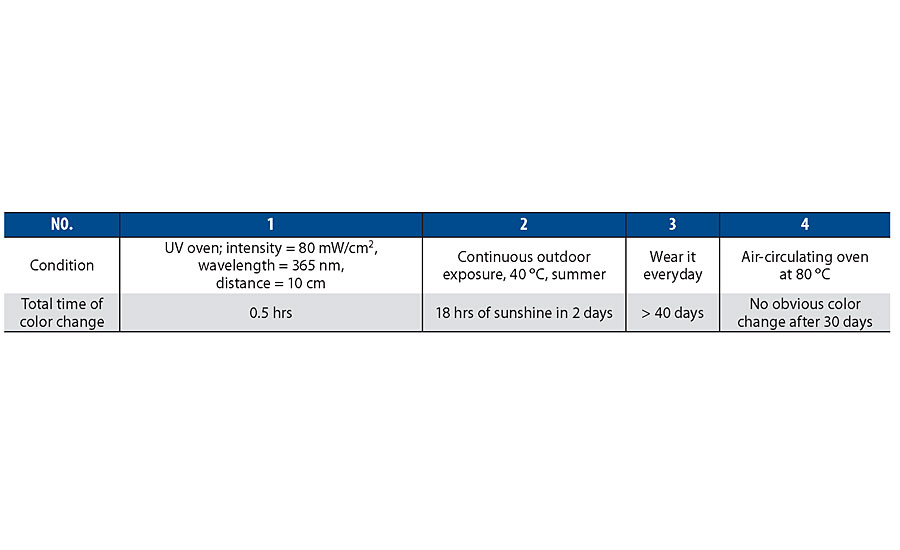

For practical use of the photosensitive haptic coatings it is important to understand the condition and timing for the change from the initial color to the final color. Therefore, the color change was studied as a function of UV intensity, time and temperature. Table 1 on the following page summarizes the results.

The following conclusions were drawn: 1) Higher-intensity UV light shortens the time of color change; 2) Compared with continuous UV irradiation, frequently applied discontinuous exposure takes more time for color change; 3) In the absence of UV light, the coating color will not change, even at elevated temperatures up to 80 ºC.

Considering the first application on athletic footwear and taking normal consumer habits of using a running shoe into account, it may take around 100 days for the coating on the athletic footwear to completely change color. Obviously, the timing for complete color change strongly depends on climate zone, time of day when used and local weather conditions, but was found to be in an interesting range for outdoor athletic footwear.

Individualization on Athletic Footwear

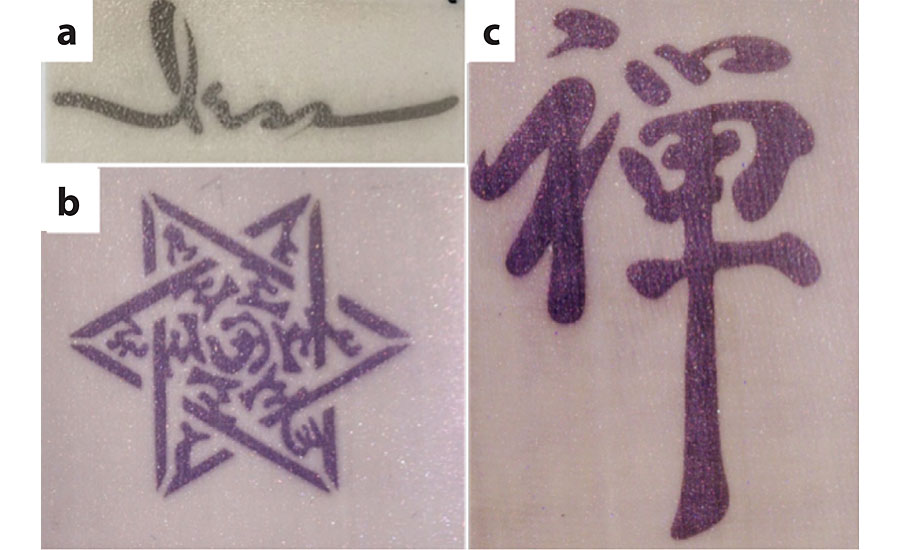

Photosensitive haptic coatings can not only achieve gradual color change on athletic footwear, but could also be used for point-of-purchase individualization. Shoes with photosensitive coatings could be efficiently manufactured in mass production. Brands and retailers could install digital cutting machines and UV light boxes within the shop environment. The digital cutting machine could quickly cut masking papers in any shape and individual customer design. With intensive artificial UV light, the masked photosensitive coating could be irradiated and will change color with a few minutes. An individual shoe design could be manufactured within the shop in less than 30 min. Figure 5 shows some individual designs created in this way.

Acknowledgments

The authors thank the haptic team of Huafeng for their fruitful discussions and support. Thanks also to our scientific cooperation partners in Xiamen and Fuzhou for their continuous support discussing all graphene-related topics.

References

1 Schmidt, T.W.; Fang, V.Z. HAPTIC - a New Additive Manufacturing Technology, Proced. of the 2nd conf. on Proceeding in Additive Manufacturing, 2016: 97, ISSN:2424 8967 :doi:10.3850/2424-8967_V02-3251.

2 Matsumoto, Y.; Koinuma, M.; Kim, S.Y.; Watanabe, Y.; Taniguchi, T.; Hatakeyama, K.; Tateishi, H.; Ida, S. Simple Photoreduction of Graphene Oxide Nanosheet under Mild Conditions[J]. ACS Applied Materials & Interfaces, 2010, 2(12), 3461-3466.

3 Williams, G.; Seger, B.; Kamat, P.V. TiO2 -Graphene Nanocomposites. UV-Assisted Photocatalytic Reduction of Graphene Oxide [J]. ACS Nano, 2008, 2(7), 1487-1491.

4 www.hapticcoating.com

For more information, e-mail thomas.schmidt@huafeng-cn.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!