Selecting the Best Diaphragm for Paints and Coatings

While the first “paints” were constructed from natural substances like charcoal, mud and berry juice, today’s paints and coatings are made of a wide variety of highly stylized components using high-tech manufacturing processes. It has been in the last 35 to 40 years that most of the major enhancements in paint and coating manufacturing have evolved. Driven by these technological advances, the market has evolved into one of the most diverse and important in the world, with paint and coatings now vital components in applications as varied as traffic marking, house coatings, automobile exteriors and aluminum cans.

Specifically, the major changes that have occurred in the industry have been paced by the introduction of new coating technologies, which have replaced traditional low-solid, solvent-based formulations. Today, synthetic pigments and stabilizers are used to mass-produce uniform batches of paint. Alkyd resins have become a major component within the production process. Sand mills and high-speed dispersion mixers are used to rapidly grind dispersible pigments. The growing demand for radiation-curable coatings, known as radcure, as well as powder coatings and nanotechnology increase demand for more environmentally safe and fast-drying end products.

While nature provided the materials for prehistoric paints, modern formulations rely on feedstocks known as binders, solvents and additives, all of which contribute to a paint’s ability to perform as expected.

Binders: The binder is the liquid, resinous part of a paint that holds all of the paint’s constituents into a solution that, after application onto a surface, enables the paint to cure into a film. Binders “bind” the pigment together, providing adhesion, integrity and toughness to the dry paint film. The binder’s resinous material is made up of polymers, which can include acrylics, alkyds, aminoplasts, cellulosics, epoxies, chloro- and fluorocarbons, natural plant oils, phenolics, polyesters, polyurethanes, silicones and vinyl.

Solvents: Also known as the “carrier,” the solvent provides a medium to get the pigment and binder from the container onto the surface that is to be painted. A solvent is a liquid that is able to lower the viscosity of a binder sufficiently to allow application onto a substrate and then evaporate to permit the formation of a paint film.

Additives: Additives are defined as low-level ingredients that provide specific paint properties, such as thickening, stabilizing, mildew resistance, defoaming, and good flow and leveling.

The overriding challenge for paint and coatings producers, then, is to find a pump technology that can reliably, efficiently and safely transfer the components of this unique concoction on the way to producing a high-performance end product.

Why AODD Pumps?

Over the years, the use of positive displacement (PD) air-operated double-diaphragm (AODD) pumps in high-volume transfer operations with high-value liquids has grown in popularity. The reasons are obvious: because of their utilitarian design, AODD pumps are highly flexible, reliable, durable and resilient when used in even the toughest pumping environments. This is due to the fact their method of operation gives them the ability to self-prime, deadhead and run dry with low shear, which allows them to immediately begin pumping when turned on and handle sensitive materials.

Their seal-less design also virtually eliminates the risk of leaks developing, which makes them ideal for handling hazardous materials. As PD pumps, they are also able to quickly reach and maintain desired flow rates throughout the entire duration of the product run. All of these features are making AODD pumps a first-choice option for the manufacture of paints and coatings.

The true genius that makes AODD pumps perfect for use in such a wide array of industries and fluid-handling applications is in their simple design and highly repeatable method of operation. The operation begins when compressed air enters the pump through its Air Distribution System (ADS), which moves one of two diaphragms away from the center of the pump. Simultaneously, the second diaphragm is pulled toward the center by the shaft that connects both diaphragms. This creates a vacuum that forces the fluid into the inlet manifold, which lifts a valve ball off its seat. This enables the fluid to travel to the outlet where it is discharged into the piping. At this time, the ball valve reseats and the piston (diaphragm plate) pulls the diaphragm away from the center of the pump, allowing the other diaphragm to enable fluid to enter its half of the pump, from where it is discharged.

Knowing how AODD pumps function, it becomes obvious that the twin diaphragms play an indispensable role in ensuring proper operation. In other words, the diaphragms can be considered the “heart” of the AODD pump.

Doing Diaphragm Due Diligence

So, paint and coatings manufacturers cannot consider diaphragms as nothing more than throwaway parts for their AODD pumps. They must perform their due diligence in order to ensure that the diaphragms they outfit their pumps with are compatible with the components that will be handled during the paint and coating production process. Not having accurate application information – most notably fluid properties and operational temperature – before outfitting an AODD pump can make selecting the proper diaphragm a challenge.

In general, the factors to consider when selecting a diaphragm include product characteristics, process temperature, application-specific requirements (i.e. FDA material of construction) and the diaphragm’s flex life. Another element to consider when selecting the diaphragm is the length of the stroke; some application/diaphragm combinations require a short-stroke pump configuration to ensure proper operation.

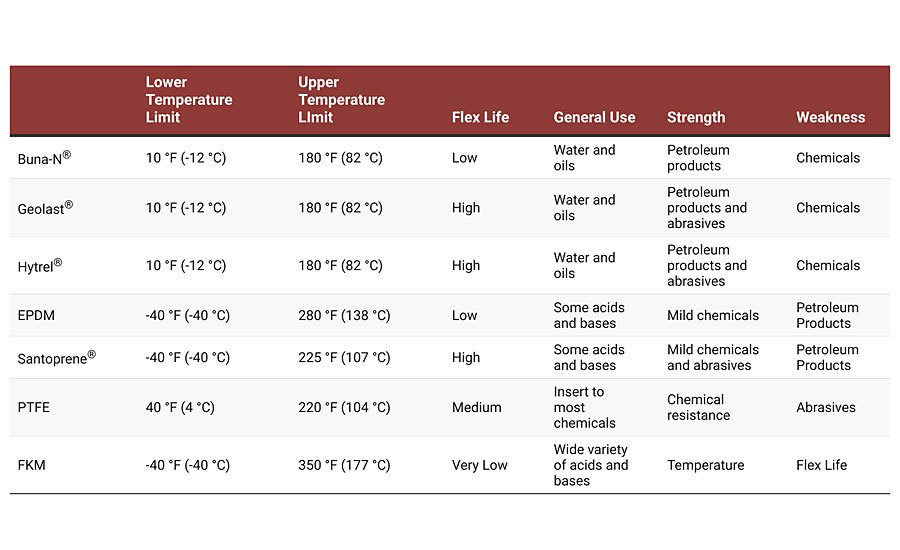

To aid its paint and coatings clients in finding the right diaphragm, All-Flo offers a seven-diaphragm portfolio that is available in rubber, thermoplastic elastomer (TPE) and polytetrafluoroethylene (PTFE) materials of construction (Table 1).

All models have been engineered to be used in specific fluid-transfer applications based on the type of fluid that is being moved.

Buna-N: Buna-N, which is also referred to as “nitrile,” is a rubber compound that provides excellent performance in applications that involve petroleum-based fluids such as leaded gasoline, fuel oils, kerosene and turpentine. Buna-N provides low to moderate flex life and moderate abrasion resistance.

Ethylene Propylene Diene Monomer (EPDM): EPDM rubber is an excellent choice for use in extreme cold temperatures or when pumping dilute acids or caustics. EPDM diaphragms are most commonly used in the manufacturing, food, pharmaceutical, and paint and coatings industries. Their flex life is lower than many other diaphragm materials, but they do exhibit good abrasion resistance. EPDM is also a good choice where statically dissipative materials are being handled.

Fluoroelastomer (FKM): FKM is a rubber compound that uses vinylidene fluoride as its monomer, which allows it to be used with a wide variety of acids and bases. It does have very low flexibility, but can be the best choice in applications where fluid temperatures can reach upwards of 350 ºF (177 ºC).

Geolast: Geolast is a TPE that exhibits enhanced oil resistance and low oil swell, which makes it perfect for the handling of petroleum products. While equivalent to Buna-N in most of its characteristics, Geolast does offer a higher level of flexibility and good abrasion resistance, all at a lower cost than fabric-reinforced Buna-N.

Hytrel: Also a TPE, Hytrel delivers high flex life and excellent abrasion resistance. It also offers superior sealing or seal energizing due to its low compression set.

Santoprene: Another member of the TPE family, Santoprene is constructed of cured EPDM rubber, which helps make it ideal for use in various applications, including the transfer of acidic and caustic liquids. It also has excellent flex life, abrasion-resistance properties and a wide temperature range that makes it the go-to diaphragm in many chemical and industrial applications. Some Santoprene formulations can also be used in sanitary fluid-handling applications.

PTFE: As an almost entirely chemically inert compound, PTFE can be used with a wide range of fluids. It is especially compatible with corrosive fluids such as aromatic or chlorinated hydrocarbons, acids, caustics, ketones and acetates.

To further assist its clients, we have created a Chemical Compatibility Chart that lists 907 materials that can be handled by an AODD pump and rates the level of compatibility (most compatible, minor effect, severe effect and not compatible) with the seven different diaphragm materials.

Conclusion

Whether pumping binders, solvents, additives or a finished product during the manufacture of paints and coatings, an AODD pump’s diaphragms must meet the needs of some very specific handling characteristics. The challenge is identifying and implementing the optimum diaphragm – one that will ensure safe, efficient, cost-effective and trouble-free operation. Choosing the correct diaphragm requires knowing and considering all of the process parameters. Because all of the parameters must work in perfect harmony in order to produce the best pumping solution, it is imperative that the user considers all options before settling on the diaphragm that will best optimize performance. This can be a daunting task for the uninitiated, so All-Flo offers assistance through its Chemical Compatibility Chart, which gives the user all of the information necessary to ensure that a diaphragm that is compatible for use in paint and coating production is chosen in all instances.

All-Flo is a product brand of PSG, a Dover Company. Find more information on All-Flo at all-flo.com and on PSG at psgdover.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!