Innovations for Sustainable Road Markings

Kraton pioneered refining crude tall oil (CTO) into biobased chemicals, including tall oil rosin, dating back to the 1930s. Refined rosin typically has a color that can vary from pale yellow to dark red, depending on the CTO source and refining effectiveness. The rosin can then be upgraded into rosin ester resin through a stabilization and esterification process. Formulators use rosin ester resins to make products for various applications, including adhesive applications like case sealing or electronics assembly and coatings applications like furniture varnishing or road marking. Formulators often prefer these biobased resins to petroleum-based alternatives due to performance advantages like adhesion and chemical resistance.

Road markings are an essential application in the coatings industry because of their critical role in road safety. Improving road safety has been an increasingly important goal for governments and road owners worldwide for many years due to the expanding world population and rising mobility. According to the World Health Organization (WHO) Global Status Report on Road Safety, road traffic accidents kill more than 1.3 million people each year. Traffic accidents are the number-one cause of death for children and young adults ages 5 through 29. Road safety experts know that road markings are among the most effective and economic countermeasures to reduce accidents. The growing trend toward vehicle automation is making road markings even more critical. Because more than half of all traffic fatalities involve lane-departure events, lane-keeping technologies have the potential to save millions of lives over time. Lane-keeping technologies depend on machine vision systems constantly identifying the center and edge lines on the roadway. Because of this dependence, several leading players in automated vehicle technology have recognized that road markings are the single most crucial piece of infrastructure to enable vehicle automation.

Key attributes that enable both human and machine visibility of road markings include the markings’ retro-reflectivity and luminance. Glass beads on the road-marking surface bounce light from a car’s headlights back to the driver, giving retro-reflectivity. Titanium dioxide and other pigments in the road marking impart luminance and whiteness, giving the marking visual contrast from unmarked pavement. These attributes offer good visibility in the nighttime and daytime. For this visibility to last, there must be good adhesion to both the road surface and the glass beads. Rosin ester resins are the preferred resin technology in high-performance hot-melt thermoplastic road markings because of the excellent adhesion they can enable.

The combination of resin and the amount of titanium dioxide plays an essential role in the road marking whiteness. With the available resins in the market, if the formulator tries to optimize cost by reducing the amount of titanium dioxide in their white marking, they tend to find that the marking loses luminance and becomes more yellow, reducing visibility for the driver and potentially failing to meet specifications. Lower color resins are needed to minimize the trade-off between visibility and cost. Kraton’s newly introduced REvolution™ technology allows for the production of near water-white rosin esters, meeting formulators’ needs.

The Challenge

Rosin ester resins can be a significant component of a thermoplastic road marking formulation. These resins allow for excellent specific adhesion to a wide range of substrates due to their polarity and polymer compatibility. Because of their low molecular weight and narrow molecular weight distribution, combined with their cycloaliphatic-aromatic structure, rosin esters have a broad compatibility with other formulating ingredients. They are used with a wide range of polymers for thermoplastic road marking paints, including ethylene-vinyl acetate (EVA), acrylics, ethylene-butyl acrylate (EBA), polyethylene (PE), and block copolymers such as styrene-isoprene-styrene (SIS) and styrene-butadiene-styrene (SBS). Applying different integrated processing steps can optimize rosin ester production yield, quality, and product consistency.

Bio-based feedstocks like CTO are typically more complex than petroleum since they have a higher degree of functionality; this makes the purification steps, in most cases, more sophisticated. However, because of their natural complexity, they are more challenging to stabilize than their petroleum-based alternatives.

The key challenge in the road marking industry is to optimize thermoplastic road markings’ performance at the lowest cost. One of the critical raw materials is titanium dioxide (TiO2), which gives whiteness to the lines and provides the hiding power to optimize light’s retro-reflectivity through the glass beads. A significant issue with titanium dioxide is the availability and related price fluctuations. The currently used resins, both rosin ester- and hydrocarbon-based, are inherently yellow-colored, requiring a certain amount of titanium dioxide to formulate white markings. Providing almost water-white rosin esters may lessen titanium dioxide use without sacrificing the performance of the thermoplastic road marking. In addition to a low initial color, providing a long pot life of the thermoplastic road marking requires a low retained color. Rosin esters must be thermally and oxidatively stable to offer a low retained color.

What Are the Current Solutions?

For improving the rosin ester characteristics outlined above, there are two catalysts used for production. The first, an esterification catalyst, is used to increase the speed of esterification (reduce cycle time) and maintain a lower rosin ester color. The second, a disproportionation catalyst, is used to reduce the initial color and improve the thermal/oxidative stability.

Innovations addressing the problem of color and stability are more than 30 years old. There is an evident need to innovate on the rosin ester chemistry and combine a light color with product stability. Over the past three decades, numerous improvements directed towards enhancing catalysts have been disclosed. The most significant inventions in this area are dating back to the 1970s and 80s. The most important esterification catalysts were discovered in the mid-80s, and the most important disproportionation catalysts in the 1970s. Note that the most recent discoveries in these two areas date back to 1986.

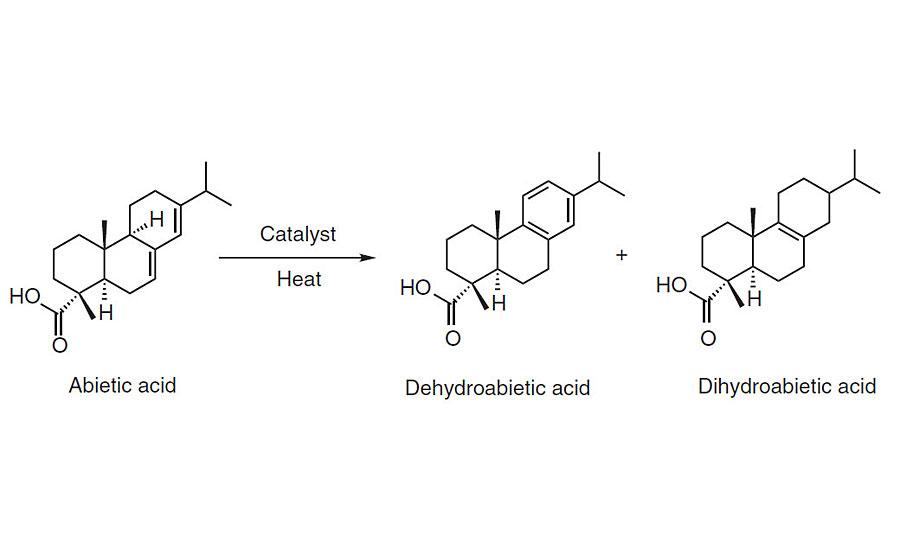

The disproportionation reaction is a method to stabilize rosin esters against oxidation. Dehydroabietic acid and dihydroabietic acid isomers are formed from abietic acid in a catalyzed conversion. The rosin disproportionation reaction involves several chemical conversions, including dehydrogenation, hydrogenation, aromatization, and olefin bond isomerization reactions. Disproportionation reduces the level of conjugated unsaturation and thereby dramatically improves oxidative stability. Disproportionation is one of the most applied stabilization methods in the industry as its implementation is substantially cost-effective (Figure 1).

Another stabilization method used in the industry is hydrogenation. The rosin or rosin ester can either be partially hydrogenated or ‘fully’ hydrogenated, where only a limited number of double bonds remain. However, this process requires high temperatures and a very high hydrogen pressure — which is more costly to operate. Although hydrogenated rosin esters' stability is significantly improved, the obtained initial colors are still relatively high. Additional processing steps to reduce the rosin ester color are typically required. For example, disproportionation, distillation, esterification, dehydrogenation, and final post-treatment step are applied in some production processes. This process results in a considerable increase in production costs, making the associated products only economically viable in high-end niche markets. For the standard-grade rosin esters, esterification and a disproportionation catalyst are used. As indicated by the patent literature, these technologies’ core development took place more than 30 years ago.

Technical Innovation

Kraton discovered a novel catalyst class, allowing for the production of near water-white rosin esters. The catalyst provides a high level of bleaching without compromising any other product characteristics. A significant advantage of the discovered technology is that it works catalytically. In other words, it enables effective practical implementation, i.e., an economically viable process that, to our knowledge, results in the lightest color rosin ester ever produced in a one-step process.

Producing very light color rosin esters will impact the thermoplastic’s visual aspect, resulting in improved whiteness of the road marking, helping support the separation of traffic during the daytime. The determination of the whiteness can be assessed according to the luminance and chromaticity coordinates. Luminance in road marking indicates the luminous intensity of light reflected on a surface at a given angle. The chromaticity coordinates are a measure of the whiteness of a surface. The coordinates indicate where the color resides in the color scale. For white thermoplastic road markings, a specified area in the color scale determines if the road marking is white or not. The combination of raw materials used in a thermoplastic road marking formulation gives the final whiteness.

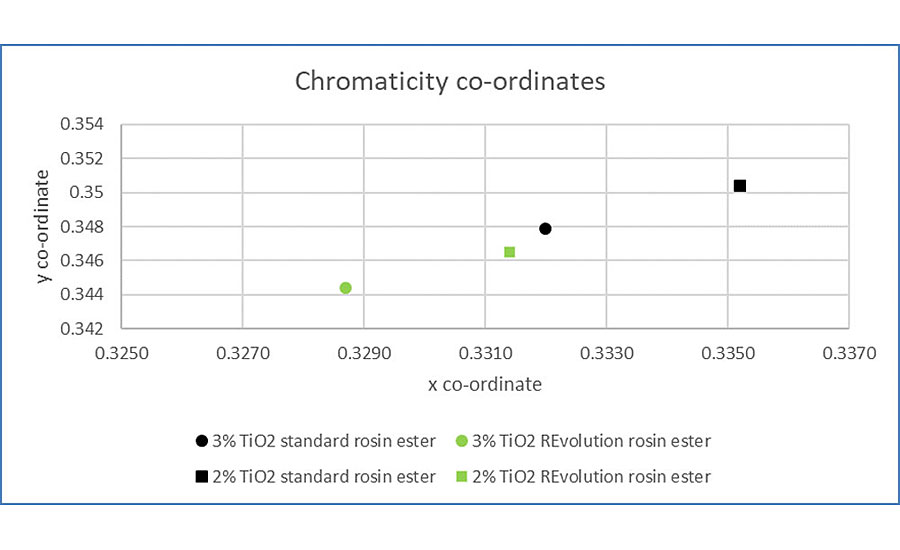

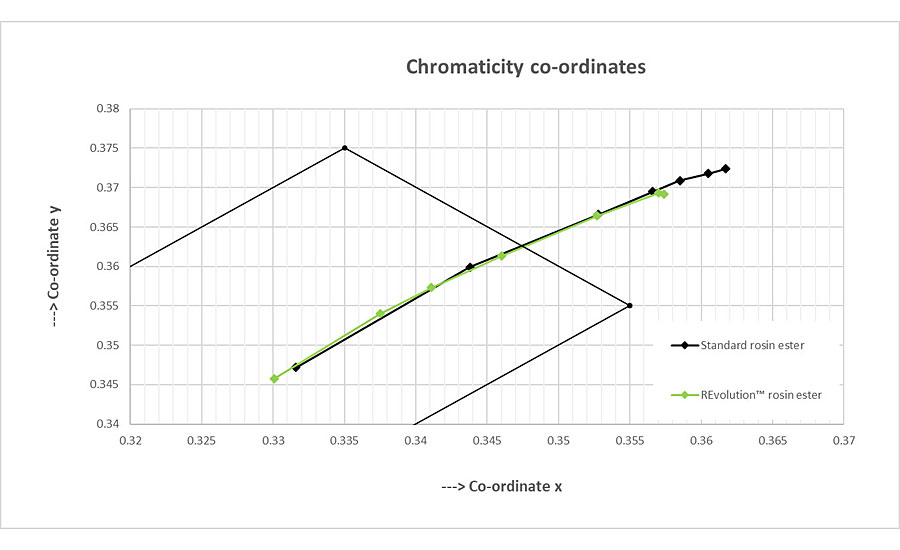

As part of Kraton’s REvolution technology, a thermoplastic road marking containing organic and inorganic raw materials is made available. Although the amount of organic raw materials is about 18 to 24%, it is a significant contributor to the color of the thermoplastic road marking. Titanium dioxide and fillers give whiteness to the thermoplastic road marking paint. If the organic raw materials are significantly colored, this color tends to reduce the overall whiteness of the thermoplastic road marking. The cause behind this is the coverage of the inorganic components by a thin layer of organic raw material when applying heat during the application process. During cooling, the system adheres to the surface and sets, giving a solid road marking. The organic raw materials can be divided into tackifiers, oils and polymers. The amount of tackifier or rosin ester used in a thermoplastic road marking varies between 14 and 18%, depending on the application method. The rosin ester color plays a critical role in the whiteness of the thermoplastic road marking. A comparison between the standard rosin ester and REvolution rosin ester, SYLVACOTE™ 4101RM, in two thermoplastic formulations with different titanium dioxide loadings are presented in Figures 2 and 3.

Figure 2 shows that using the new rosin esters contributes to improving the whiteness of the thermoplastic road marking paints compared to standard rosin esters. Focusing on the chromaticity coordinates, the results indicate that a formulation containing 2% titanium dioxide with a REvolution rosin ester maps very closely in coordinates to a formulation containing 3% titanium dioxide with standard rosin ester. As such, using the new rosin ester will improve the whiteness of a thermoplastic road marking using the same titanium dioxide content, or possibly reducing the titanium dioxide content to achieve the same results.

Thermoplastic road marking applications need to use a thermal stabilized resin to have a good pot life during the application process. With this new technology, the rosin ester’s thermal stability improves the thermoplastic road marking to stay within the chromaticity coordinates specification box twice as long as conventionally produced rosin esters. Figure 3 represents the shift occurring when continuously heating a thermoplastic paint for 30 hours and taking samples at intervals of 6 hours. The test thermoplastic road marking formulation contains 16% rosin ester and 3% titanium dioxide. A standard-produced rosin ester used in a thermoplastic formulation will fall out of specification after 12 hours, while a REvolution rosin ester-based formulation will fall out of specification after 24 hours.

As explained with both figures, using very pale or close to water-white rosin esters is beneficial to increase the thermoplastic paint’s whiteness. The hiding power of titanium dioxide increased due to the thin layer of organic materials, of which the rosin ester is the major component. The new rosin esters improve the daytime visibility of the thermoplastic road marking.

The emphasis of this article is on the chromaticity coordinates to demonstrate the efficiency of this new technology. Other critical parameters as day and nighttime retro-reflectivity will be assessed to determine if this new technology will bring the retro-reflectivity to the next level.

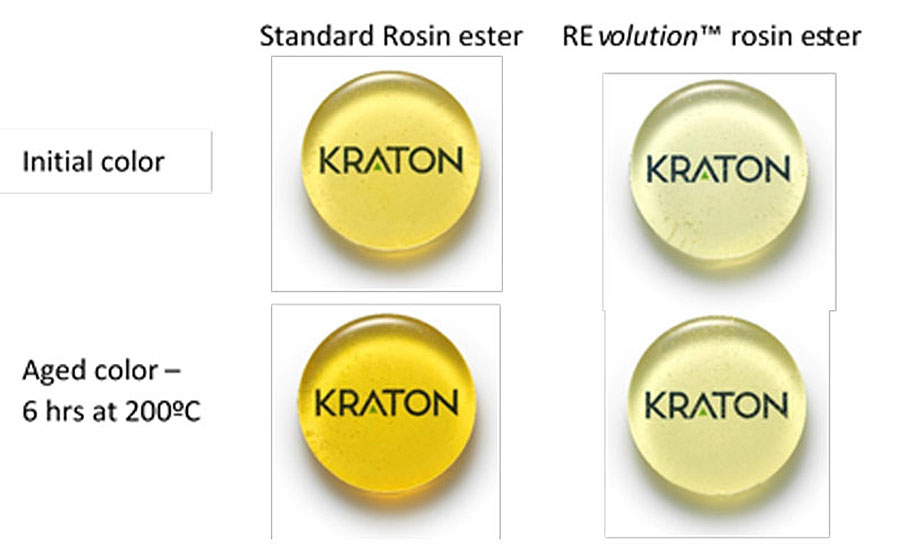

Kraton is offering a step-change innovation in the area of rosin ester catalysis with this new platform. The new technology allows for rosin ester’s production with significantly improved color and oxidative stability in a cost-effective way (Figure 4). These benefits are critical parameters required in various industries, such as adhesives and road marking. The ability to meet these performance requirements will drive further demand for sustainable solutions.

The new technology has long passed proof-of-concept. It has been scaled up and commercialized for more than a year. The platform was first tested on rosin esters in Europe and has expanded to Kraton plants globally.

When applying the REvolution process to Kraton’s existing rosin ester, it is designed to deliver a resin based on renewable resources close to water-white and highly stable. With the increased interest in sustainable solutions for the construction market, rosin esters are an immediate solution to improve the life cycle assessment of thermoplastic road marking formulations. Cradle-to-gate life cycle assessments indicate that Kraton rosin ester resins, including this new technology, generate less than half of the fossil-based carbon dioxide emissions of petroleum-based alternative resins.

Conclusion

We have developed a unique, biobased solution designed for thermoplastic road marking formulations with its REvolution technology. Performance criteria such as whiteness and retro-reflectivity are essential for the end user. This new technology improves two critical performance characteristics in a rosin ester, initial light color, and oxidative stability. The unique, biobased rosin ester resin presented in this article serves as an alternative to petroleum-based resins in thermoplastic road marking formulations. For product lines where life cycle assessment is critical, Kraton rosin ester products are an excellent alternative to reduce greenhouse gas emissions and improve the finished product's overall life cycle assessment.

Our next generation of rosin esters offers excellent bonding strength, improved light color, and high stability while providing thermoplastic road marking formulators with a new choice of high-performance biobased tackifiers. For more information, visit revolutionrosinesters.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!